Quality guarantee state indicator and preparation method thereof

A state indicator and indicator technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc. requirements, did not point out how to use the specific plan of the indicator, etc., to achieve the effect of ensuring service life, excellent moisture permeability, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

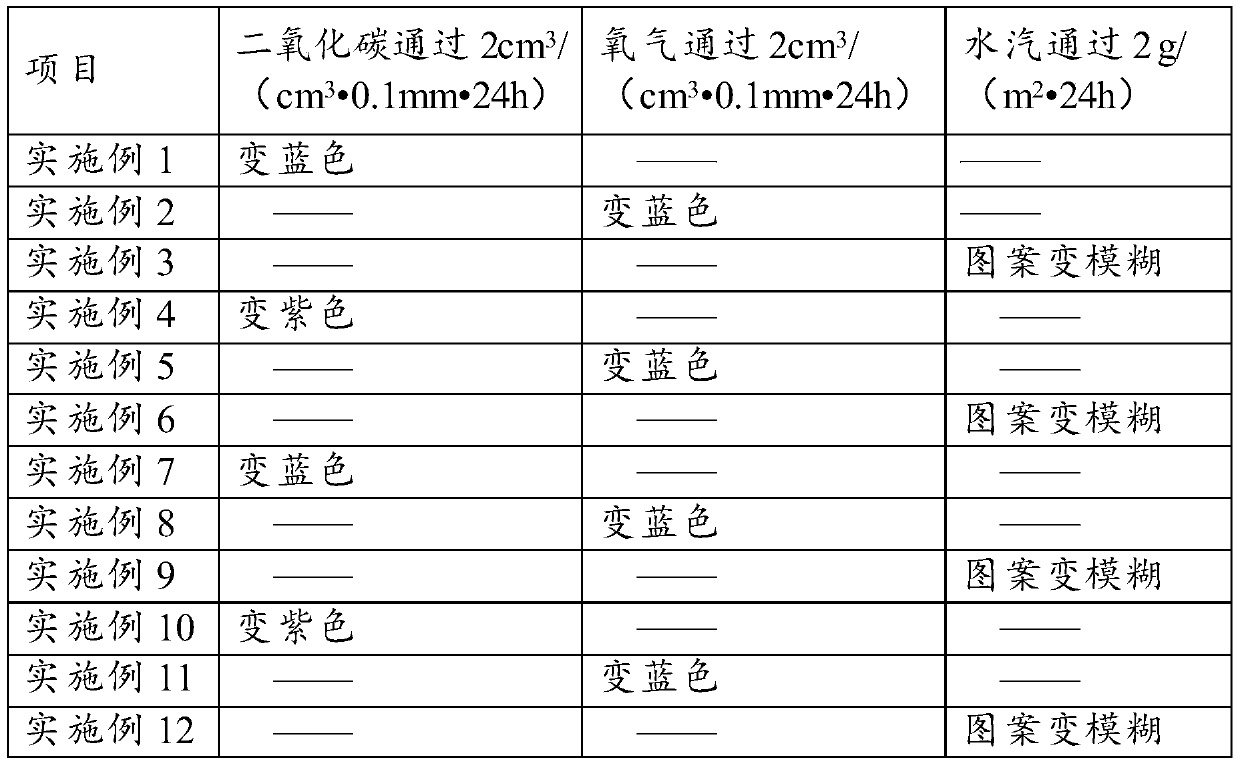

[0065] The present invention has no special limitation on the preparation method of the carbon dioxide indicator. In some embodiments of the present invention, the carbon dioxide indicator is obtained by mixing a carbon dioxide sensitive reactive dye, an alkaline substance and a solvent. Wherein the alkaline substance used is a commonly used inorganic base, the added amount is enough to ensure that the pH value of the carbon dioxide indicator is not less than 8.5, and the added amount of the solvent is enough to ensure that the concentration of the indicator is 0.1wt%-1wt%.

[0066] In certain embodiments of the invention, the oxygen indicator comprises an oxygen sensitive reactive dye and a solvent. In some embodiments of the present invention, the oxygen-sensitive reactive dyes include methylene blue, azure B, Nile blue, ruthenium terpyridine, ruthenium perchlorate, platinum octaethylporphyrinone, and proflavin one or several. In some embodiments of the present invention, t...

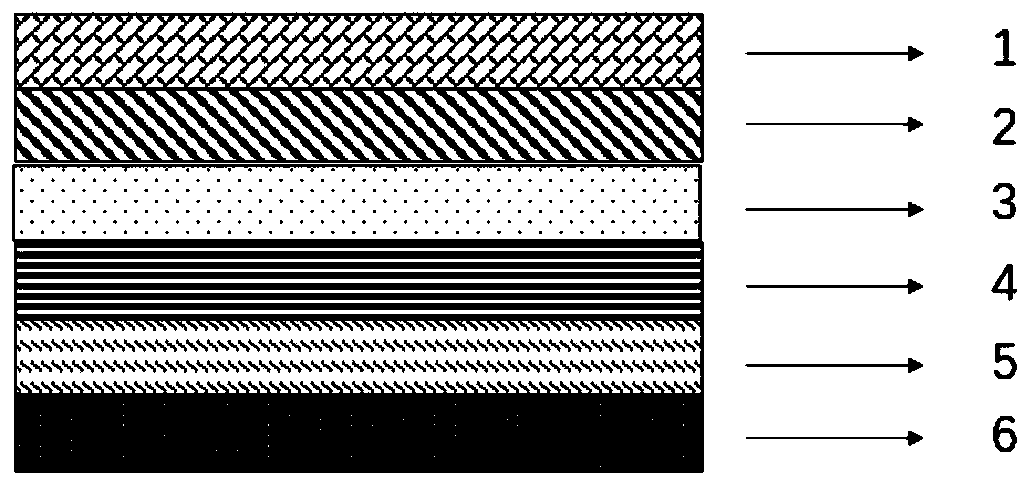

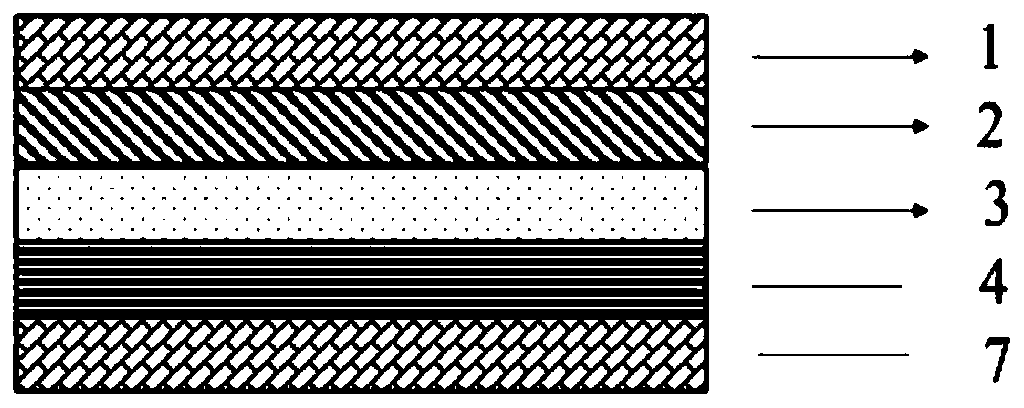

Embodiment 1

[0161] The polytetrafluoroethylene film (ePTFE, 100 μ m) is placed in the position where the dry compound machine is placed, and its surface is coated with polyurethane adhesive (Henkel 3100, the coating amount of the adhesive is 3g / m 2 ) and carbon dioxide indicator (reactive dyestuff is thymolphthalein, alkaline substance is potassium hydroxide, solvent is glycerin, the pH value of carbon dioxide indicator is 8.5, and the concentration of carbon dioxide indicator is 1wt%) mixed reagent, will complete coating The first permeable membrane of the cloth is dried in a drying tunnel at 10°C for 24h, then, the mixed reagent coated is melted under heating, and placed on the porous substrate (starch grafted) Acrylamide porous substrate, 230μm) lamination, after cooling, pressing, winding and curing, the first lamination film is formed;

[0162] Then the first lamination is placed in the position where the dry composite machine is placed, and polyurethane adhesive (Henkel 3100, the co...

Embodiment 2

[0165] The composite film (180 μm) obtained by bonding polytetrafluoroethylene film (ePTFE) and polyethylene film (PE) is placed in the position where the dry laminating machine is placed, and its surface is coated with polyurethane adhesive (Henkel3100, the coating amount of adhesive for, 3g / m 2 ) and an oxygen indicator (methylene blue, the solvent is glycerin, the mass ratio of methylene blue to glycerin is 1:50), and the coated first permeable membrane is dried in the oven at 10°C for 24h, Then, melt the coated mixed reagent in a heated state, and stick to the porous substrate (starch grafted acrylamide porous substrate, 230 μm) placed in the second place of the dry composite machine, cool, press, After winding and aging, the first laminating film is formed;

[0166] Then the first lamination is placed in the position where the dry composite machine is placed, and polyurethane adhesive (Henkel 3100, the coating amount of the adhesive is 3g / m2) on the porous substrate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com