Flexible direct-current generator based on organic semiconductor film

An organic semiconductor, DC generator technology, applied in the direction of triboelectric generators, etc., can solve the problems of low output current and power, hinder development and production application, and unfavorable miniaturization integration, and achieve stable device operation, simple structure and high voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Take two flexible polyethylene terephthalate (PET) substrates of appropriate size, put the substrates in acetone solution and ethanol solution to clean the substrate surface in order to remove impurities attached to the surface , and use N 2 blow dry;

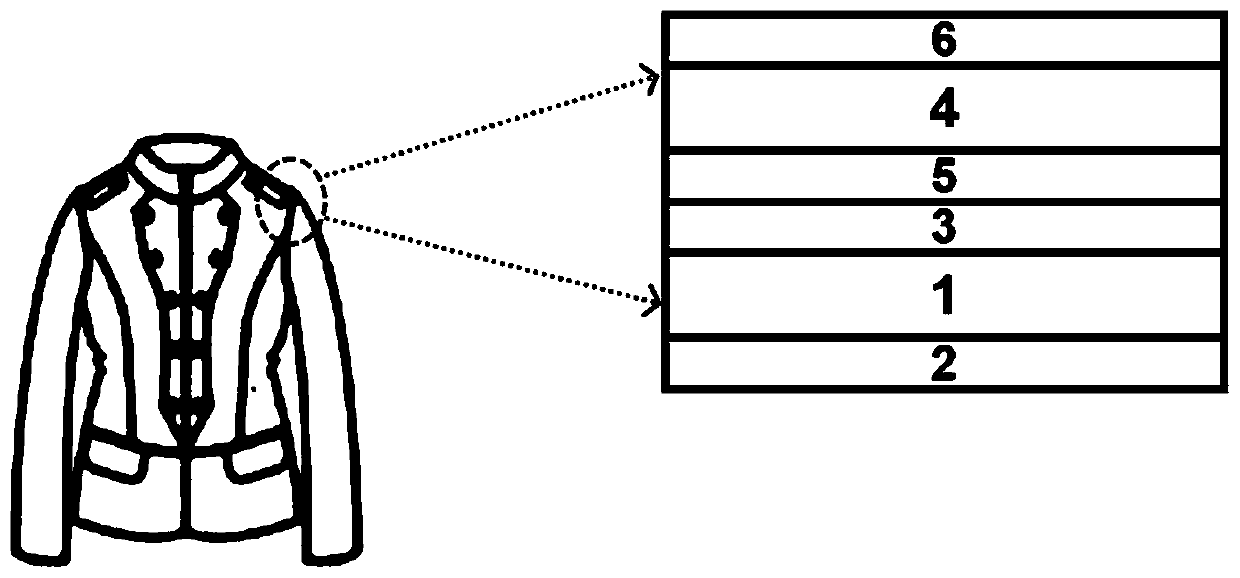

[0029] 2) Select one side as the front side on a PET flexible substrate, make an electrode on the surface, the material is a 50nm silver electrode, and prepare a polyvinylcarbazole (PVK) organic semiconductor film on the electrode surface by spin coating;

[0030] 3) Select one side as the front side on another PET flexible substrate, make electrodes on the surface, the material is 50nm silver electrode, and prepare poly[9,9-dioctylfluorene] (PFO) organic semiconductor on the electrode surface by spin coating method film;

[0031] 4) Press the front side of the flexible substrate spin-coated with PFO organic semiconductor thin film on the front side of the flexible substrate spin-coated with PVK organic semiconductor ...

Embodiment 2

[0034] 1) Take two indium tin oxide (ITO) flexible substrates of appropriate size, put the substrates into acetone solution and ethanol solution to clean the surface of the substrates, remove impurities attached to the surface, and clean them with N 2 blow dry;

[0035] 2) Select one side as the front side on an ITO flexible substrate, make an electrode on the surface, the material is a 50nm silver electrode, and then prepare a polyvinylcarbazole (PVK) organic semiconductor film on the electrode surface by spin coating;

[0036] 3) Select one side as the front side on another PET flexible substrate, make electrodes on the surface, the material is 50nm silver electrode, and prepare poly[9-(1-octylnonyl)-9H-carbazole] by spin coating method on the electrode surface (PCZ) organic semiconductor thin film;

[0037] 4) Press the front side of the flexible substrate spin-coated with PCZ organic semiconductor thin film on the front side of the flexible substrate spin-coated with PVK ...

Embodiment 3

[0040] 1) Take two indium tin oxide (ITO) flexible substrates of appropriate size, put the substrates into acetone solution and ethanol solution to clean the surface of the substrates, remove impurities attached to the surface, and clean them with N 2 blow dry;

[0041] 2) Select one side as the front side on an ITO flexible substrate, make an electrode on the surface, the material is a 50nm gold electrode, and prepare poly[2-methoxy-5-(2-ethylhexyl oxide) on the electrode surface by spin coating Base) -1,4-phenylacetylene] (MEH-PPV) organic semiconductor film;

[0042] 3) Select one side as the front side on another ITO flexible substrate, make electrodes on the surface, the material is a 50nm gold electrode, and prepare poly[9-(1-octylnonyl)-9H-carbazole] by spin coating on the electrode surface (PCZ) organic semiconductor thin film;

[0043] 4) Press the front side of the flexible substrate spin-coated with PCZ organic semiconductor film on the front side of the flexible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com