Zinc oxide nanoparticle ink and electroluminescent device

A technology of zinc oxide nanoparticles and particles, which is applied in the field of nanometers, can solve the problems of poor film quality of the electron transport layer, easy blockage of nozzles, easy aggregation of zinc oxide nanoparticles, etc., and achieve excellent luminescent properties, reduce adverse effects, and zinc oxide thin films even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a zinc oxide nanoparticle ink, including: ZnO nanoparticles with a mass ratio of 5%; diethylene glycol butyl ether with a mass ratio of 36.5% (the first solvent, the boiling point is about 230° C.); 18.1% by mass of 2,5-hexanediol (the second solvent, the boiling point is about 216°C); 22.3% by mass of isononanol (the second solvent, the boiling point is about 193°C); 13.3% isoamyl isovalerate (the third solvent, boiling point is about 193°C); 1H, 1H, 2H, 2H-perfluorooctanol (the fourth solvent, boiling point is about 4.8% by mass) 174°C). The preparation method of the zinc oxide nanoparticle ink adopts the direct mixing of ZnO nanoparticles and a solvent.

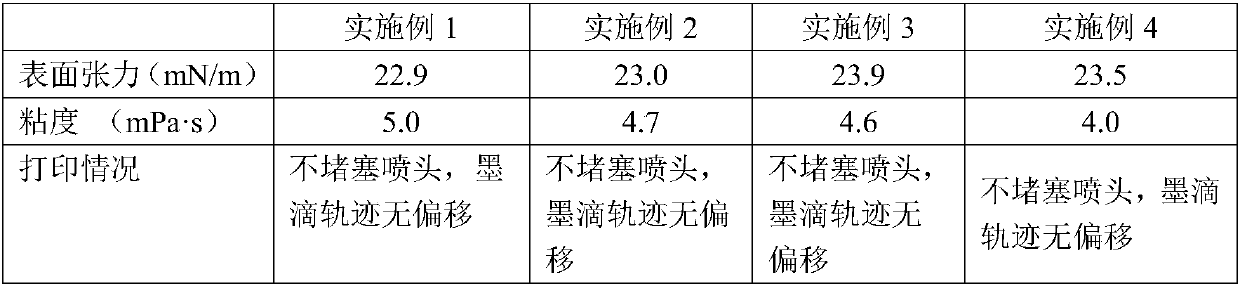

[0037] In Example 1, the zinc oxide nanoparticle ink remained stable after being placed for 30 days, and no agglomeration or precipitation occurred. At 25°C, the viscosity and surface tension properties of the zinc oxide nanoparticle ink were tested, and the results are shown in Table 1. ...

Embodiment 2

[0048] This embodiment provides a zinc oxide nanoparticle ink, including: ZnMgO nanoparticles with a mass ratio of 2%; diethylene glycol methyl ether with a mass ratio of 31.8% (the first solvent, the boiling point is about 193° C.); 2,4-pentanediol with a mass ratio of 16.7% (the second solvent, with a boiling point of about 200 °C); isononanol with a mass ratio of 24.8% (the second solvent, with a boiling point of about 193 °C); 20.2% isoamyl isovalerate (the third solvent, boiling point is about 193°C); 1H, 1H, 2H, 2H-perfluorooctanol (the fourth solvent, boiling point is about 4.5% by mass) 174°C). The preparation method of the zinc oxide nanoparticle ink adopts the direct mixing of ZnMgO nanoparticles and a solvent.

[0049] In Example 2, the zinc oxide nanoparticle ink remained stable after being placed for 30 days, and no agglomeration or precipitation occurred. At 25°C, the viscosity and surface tension properties of the ink were tested, and the results are shown in ...

Embodiment 3

[0060] This embodiment provides a zinc oxide nanoparticle ink, including: ZnMgLiO nanoparticles with a mass ratio of 48.1%; dipropylene glycol methyl ether (a first solvent, with a boiling point of about 190° C.) with a mass ratio of 48.1%; and a mass ratio of 10.3 % of 1,4-butanediol (the second solvent, the boiling point is about 228°C); 19.4% of isononanol (the second solvent, the boiling point of about 193°C) by mass; 10.5% by mass of isononanol Isoamyl butyrate (the third solvent, the boiling point is about 179°C); 1H,1H,7H-dodecafluoro-1-heptanol (the fourth solvent, the boiling point is about 170°C) with a mass ratio of 8%. The preparation method of the zinc oxide nanoparticle ink adopts the direct mixing of ZnMgLiO nanoparticles and a solvent.

[0061] In Example 3, the zinc oxide nanoparticle ink remained stable after being placed for 30 days, and no agglomeration or precipitation occurred. At 25°C, the viscosity and surface tension properties of the ink were tested,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com