Microdefect-induced electrochromic intelligent glass composite membrane group and preparation method thereof

An electrochromic and smart glass technology, applied in the direction of ion implantation plating, coating, instruments, etc., can solve the problems of affecting the discoloration time of the material, the discoloration process is easy to be uneven, and the reaction rate is affected, so as to improve the uniformity of discoloration, Improve the color changing efficiency and speed up the coloring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

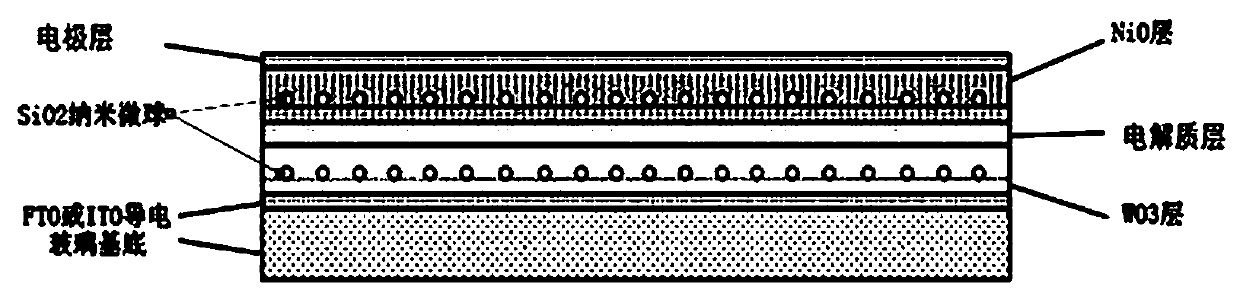

[0016] (1) Preparation of embedded SiO 2 WO of nanospheres 3 Layer: On the FTO or ITO surface of the FTO or ITO conductive glass substrate, first prepare WO with a thickness of 20nm by DC reactive magnetron sputtering 3 layer, followed by scrape coating, coating 5% solid content silicon oxide nanosphere emulsion on WO 3 layer, in WO 3 Discrete SiO 2 Microspheres, the diameter of which is 100nm; the WO with a thickness of 300nm was prepared by DC reactive magnetron sputtering again 3 layer, wherein the target material of magnetron sputtering is a metal plane tungsten target, the sputtering pressure is 0.37Pa, the sputtering power is 800W, the sputtering argon flow rate is 200sccm, and the oxygen flow rate is 55sccm;

[0017] (2) Preparation of electrolyte layer: WO prepared in step (1) 3 On the layer, a layer of Li with a thickness of 100 nm was prepared by DC reactive sputtering method. x Ga y O layer, the target used is Li, Ga alloy target, the Li / Ga mixing mass ratio ...

Embodiment 2

[0021] (1) Preparation of embedded SiO 2 WO of nanospheres 3 Layer: On the FTO or ITO surface of the FTO or ITO conductive glass substrate, first prepare WO with a thickness of 50nm by DC reactive magnetron sputtering 3 layer, followed by scrape coating, coating 5% solid content silicon oxide nanosphere emulsion on WO 3 layer, in WO 3 Discrete SiO 2 Microspheres, the diameter of the microspheres is 50nm; the WO with a thickness of 200nm is prepared by DC reactive magnetron sputtering again. 3 layer, wherein the magnetron sputtering target is a metal flat tungsten target, the sputtering pressure is 1.0Pa, the sputtering power is 1000W, the sputtering argon flow rate is 450 sccm, and the oxygen flow rate is 120 sccm;

[0022] (2) Preparation of electrolyte layer: WO prepared in step (1) 3 On the layer, a layer of Li with a thickness of 200nm was prepared by DC reactive sputtering method. x Ga y O layer, the target used is Li, Ga alloy target, the Li / Ga mixing mass ratio i...

Embodiment 3

[0026] (1) Preparation of embedded SiO 2 WO of nanospheres 3 Layer: On the FTO or ITO surface of the FTO or ITO conductive glass substrate, first prepare WO with a thickness of 90nm by DC reactive magnetron sputtering 3 layer, followed by scrape coating, coating 5% solid content silicon oxide nanosphere emulsion on WO 3 layer, in WO 3 Discrete SiO 2 Microspheres, the diameter of the microspheres is 20nm; the WO with a thickness of 150nm is prepared again by the DC reactive magnetron sputtering method 3 layer, wherein the magnetron sputtering target is a metal planar tungsten target, the sputtering pressure is 1.5Pa, the sputtering power is 1500W, the sputtering argon flow rate is 450 sccm, and the oxygen flow rate is 50 sccm;

[0027] (2) Preparation of electrolyte layer: WO prepared in step (1) 3 On the layer, a layer of Li with a thickness of 300nm was prepared by DC reactive sputtering method. x Nb y O layer, the targets used are Li and Nb alloy targets, the Li / Ga mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com