Monatomic noble metal anchoring defect type WO3/TiO2 nanotube as well as preparation and application thereof

A nanotube and noble metal technology, applied in the field of photocatalytic materials, can solve the problems of easy deactivation, limited capacity, poor photocatalytic performance, etc., and achieve the effect of high efficiency, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A single-atom noble metal-anchored defect-type WO 3 / TiO 2 A method for preparing a nanotube composite, comprising the steps of:

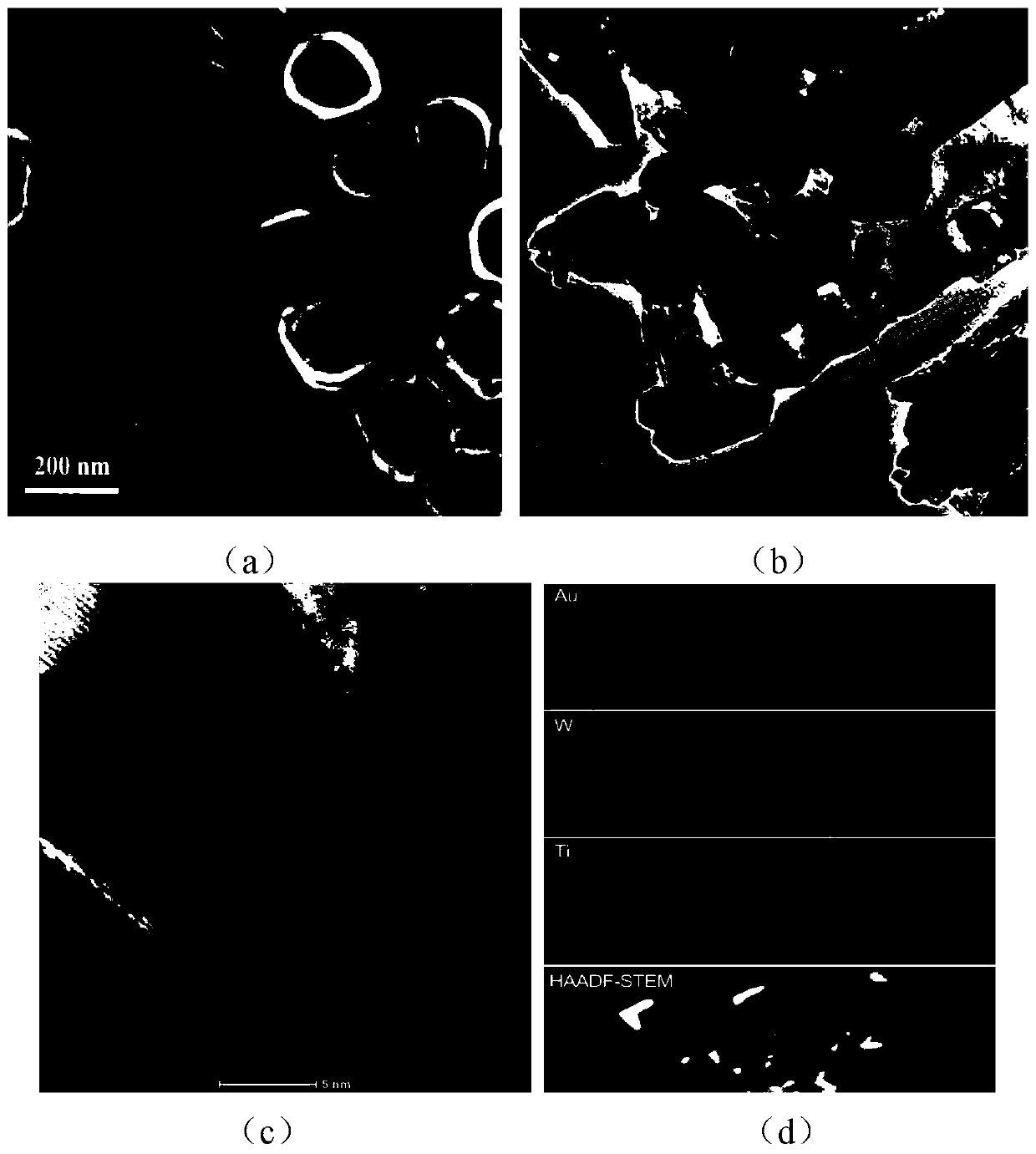

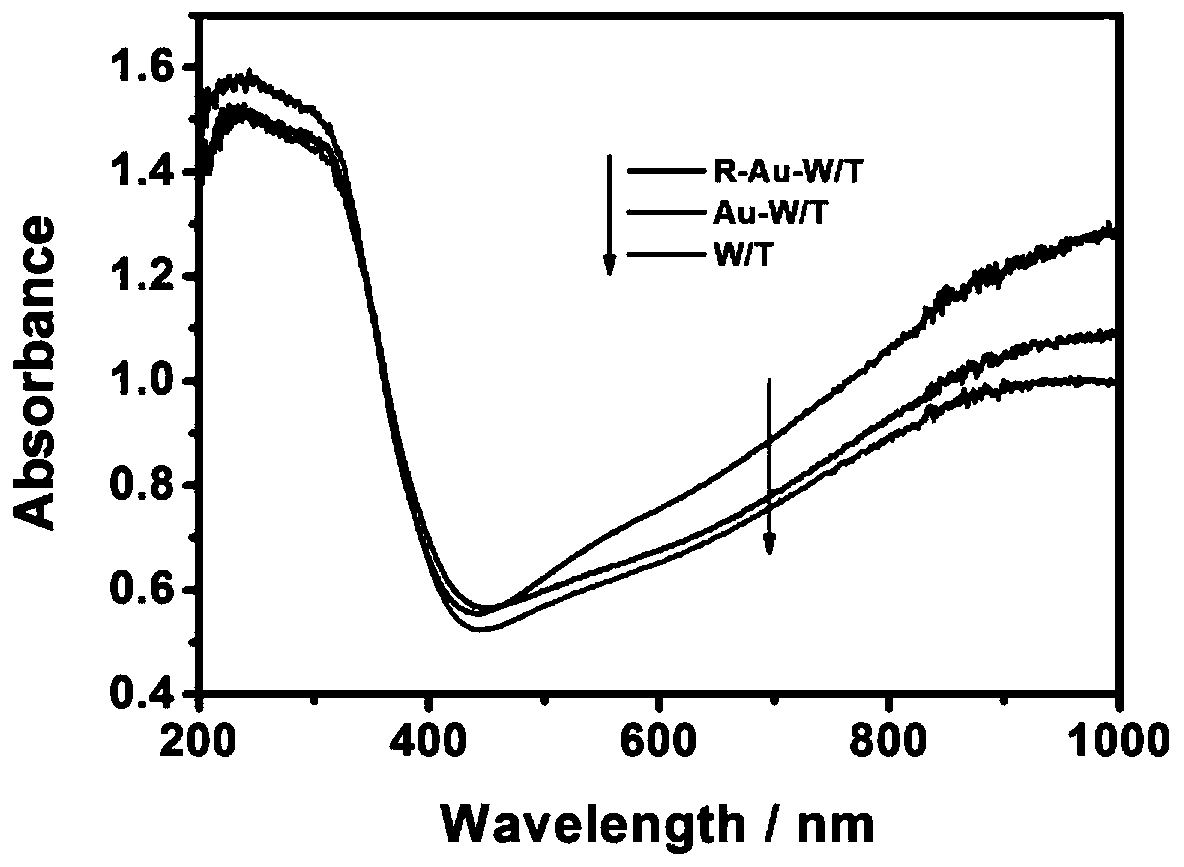

[0046] (1) in TiO 2 Depositing WO on the inner and outer walls of nanotubes 3 nanoparticles, calcined so that the WO 3 Nanoparticles crystallized to obtain WO loaded on the inner and outer walls 3 Nanoparticles of TiO 2 nanotube;

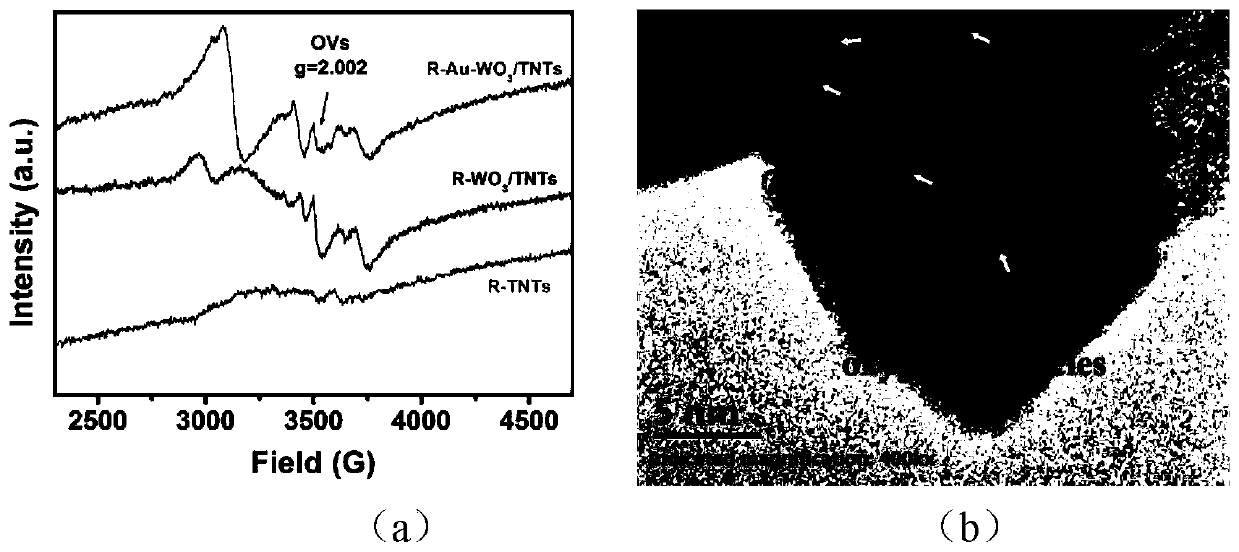

[0047] (2) Loaded WO on the inner and outer walls obtained in step (1) 3 Nanoparticles of TiO 2 Nanotubes undergo electrochemical reduction, and by controlling the potential and time of electrochemical reduction, some WO 3 The nanoparticles are reduced to form W 5+ defects, resulting in W 5+ Defective WO 3 Nanoparticle loaded TiO 2 Nanotube composites;

[0048] (3) with the step (2) obtained containing W 5+ Defective WO 3 Nanoparticle loaded TiO 2 The nanotube composite is used as the working electrode, and noble metal single atoms are supported in the composite by electrochemical deposition. WO 3...

Embodiment 1

[0081] A modified TiO 2 A method for preparing a nanotube-based visible light photocatalyst, comprising the following steps: the photocatalyst is visible light responsive TiO 2 Nanotube-based photocatalysts.

[0082] (1) Preparation of TiO 2 nanotube

[0083] The Ti sheet was cut to a size of 3cm×3.5cm, immersed in an ethylene glycol solution containing 3.119g / L ammonium fluoride and 13.75% (volume ratio) deionized water under a two-electrode system, and a platinum electrode was used as a counter electrode at 60V Voltage etching for 8 hours. Will get TiO 2 The nanotube precursor was placed in a muffle furnace and calcined at 450 °C for 120 min to obtain anatase TiO 2 nanotube.

[0084] (2) Preparation of WO 3 / TiO 2 nanotube

[0085] With the TiO obtained in step (1) 2 The nanotube was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. 3 Electrochemic...

Embodiment 2

[0110] A modified self-doping TiO 2 A method for preparing a nanotube-based visible light photocatalyst, comprising the following steps: the photocatalyst is visible light responsive TiO 2 Nanotube-based photocatalysts.

[0111] (1) Preparation of TiO 2 nanotube

[0112] The Ti sheet was cut to a size of 3cm×3.5cm, immersed in an ethylene glycol solution containing 0.1g / L ammonium fluoride and 20% (volume ratio) deionized water under a two-electrode system, and a platinum electrode was used as a counter electrode at 20V Voltage etching for 20 hours. Will get TiO 2 The nanotube precursor was placed in a muffle furnace and calcined at 400 °C for 240 min to obtain anatase TiO 2 nanotube.

[0113] (2) Preparation of WO 3 / TiO 2 nanotube

[0114] With the TiO obtained in step (1) 2 The nanotube was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. 3 Elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com