Foaming hot melt adhesive and preparation process thereof

A production process and foaming heat technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of incomplete melting of raw materials, no flame retardancy, large particle size of raw materials, etc. Achieve the effect of improving the melting effect, improving the crushing effect, and improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A foaming hot melt adhesive, including APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant, the composition ratio of the above raw materials is, APAO random polyalphaolefin 40%, polyethylene wax 11%, antioxidant 0.5%, C5 petroleum resin 40%, foaming agent 3.5%, flame retardant 5%.

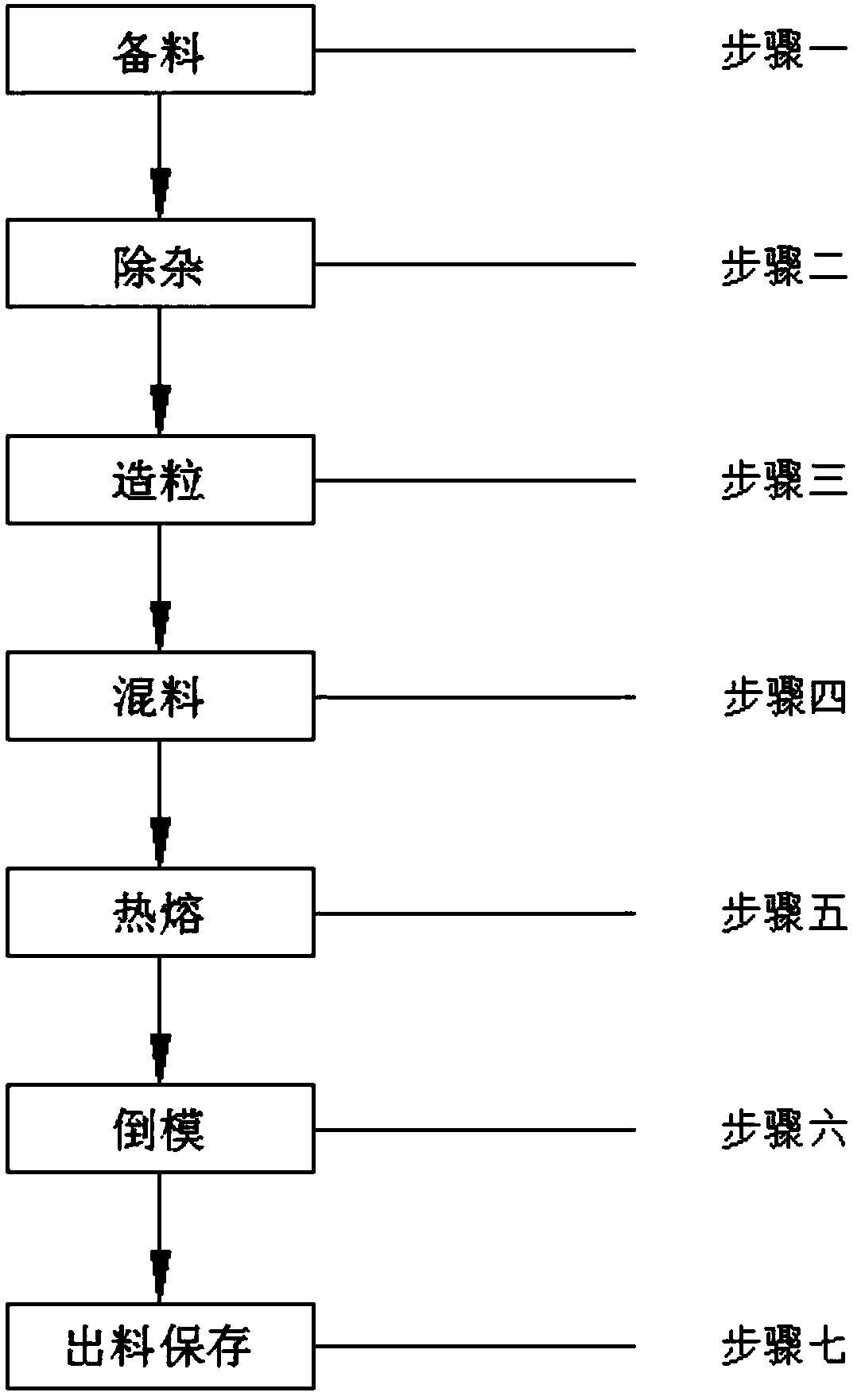

[0031] A manufacturing process of foamed hot-melt adhesive, comprising the following steps: Step 1, material preparation; Step 2, impurity removal; Step 3, granulation; Step 4, mixing materials; Step 5, hot melting; Step 6, mold inversion; Step 7, discharging and saving;

[0032] Wherein in the above-mentioned step 1, APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant are selected as raw materials, according to APAO random polyalphaolefin 40%, polyethylene 11% wax, 0.5% antioxidant, 40% C5 petroleum resin, 3.5% foaming agent, 5% flame retardant, and store separately a...

Embodiment 2

[0041] A foaming hot melt adhesive, including APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant, the composition ratio of the above raw materials is, APAO random polyalphaolefin 45%, polyethylene wax 7%, antioxidant 0.3%, C5 petroleum resin 38%, blowing agent 4%, flame retardant 5.7%.

[0042]A manufacturing process of foamed hot-melt adhesive, comprising the following steps: Step 1, material preparation; Step 2, impurity removal; Step 3, granulation; Step 4, mixing materials; Step 5, hot melting; Step 6, mold inversion; Step 7, discharging and saving;

[0043] Wherein in the above-mentioned step 1, APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant are selected as raw materials, according to APAO random polyalphaolefin 45%, polyethylene 7% wax, 0.3% antioxidant, 38% C5 petroleum resin, 4% foaming agent, 5.7% flame retardant, and store separately afte...

Embodiment 3

[0052] A foaming hot melt adhesive, including APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant, the composition ratio of the above raw materials is, APAO random polyalphaolefin 50%, polyethylene wax 9%, antioxidant 0.8%, C5 petroleum resin 35%, foaming agent 2.2%, flame retardant 3%.

[0053] A manufacturing process of foamed hot-melt adhesive, comprising the following steps: Step 1, material preparation; Step 2, impurity removal; Step 3, granulation; Step 4, mixing materials; Step 5, hot melting; Step 6, mold inversion; Step 7, discharging and saving;

[0054] Wherein in the above-mentioned step 1, APAO random polyalphaolefin, polyethylene wax, antioxidant, C5 petroleum resin, foaming agent and flame retardant are selected as raw materials, according to APAO random polyalphaolefin 50%, polyethylene 9% wax, 0.8% antioxidant, 35% C5 petroleum resin, 2.2% foaming agent, 3% flame retardant, and store separately aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com