A method for preparing low-crystallinity high-elasticity nylon 66 by utilizing gold extraction waste liquid

A low-crystallinity, gold-extracting waste liquid technology, applied in the manufacture of rayon, single-component polyamide rayon, textiles and papermaking, etc., can solve the problems of difficult elements to handle, low elongation at break of nylon 66 fiber, etc. , to achieve the effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

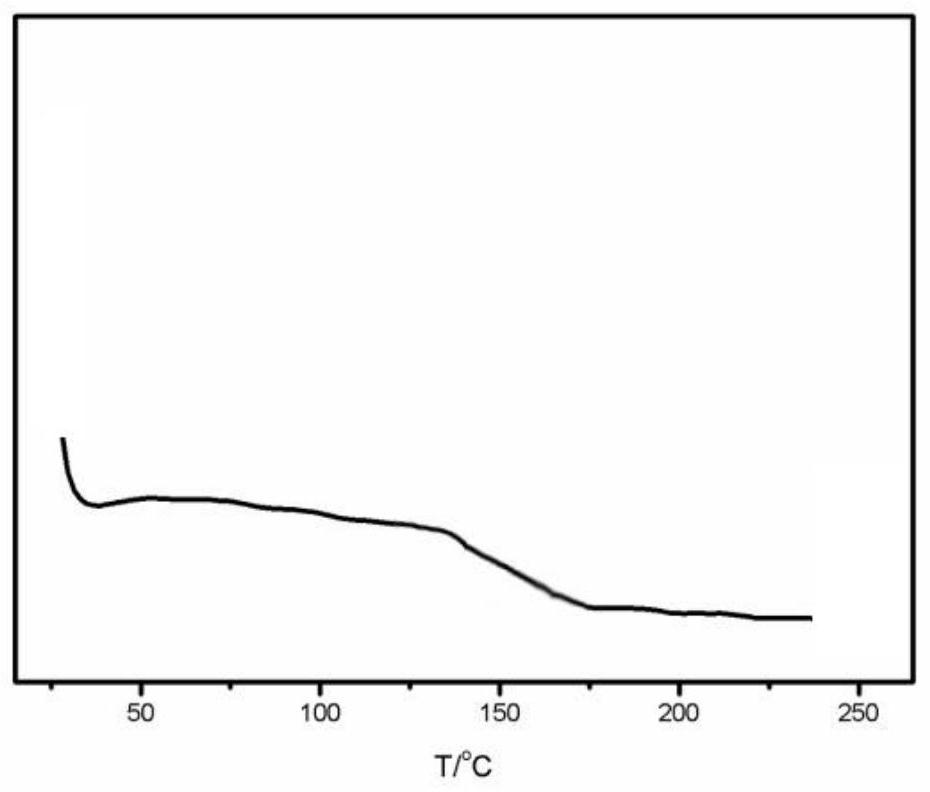

Image

Examples

Embodiment 1

[0015] A method for preparing low-crystallinity high-elastic nylon 66 by utilizing gold extraction waste liquid, comprising the following steps:

[0016] 1) The waste liquid after extraction of gold and silver is left to stand, take the supernatant, add hydrochloric acid to adjust the pH to 1, heat and concentrate until precipitation occurs and stop, to obtain a concentrated solution;

[0017] 2) Filter the PA66 powder with a relative viscosity of 1.8, take the particles with a particle size between 600 meshes, add it to the concentrated solution obtained in step 1), control the weight ratio of the concentrated solution to the polyamide powder to be 5:1, and stir at 40°C While adding calcium formate powder, the amount of calcium formate powder added is 2 times of that in PA66 powder, stirring and reacting for 5h, and then standing for filtration to obtain a solid reactant;

[0018] 3) drying the solid reactant obtained in step 2) at 60°C, and melting and granulating to obtain ...

Embodiment 2

[0021] A method for preparing low-crystallinity high-elastic nylon 66 by utilizing gold extraction waste liquid, comprising the following steps:

[0022] 1) the waste liquid after the gold and silver extraction is left to stand, take the supernatant, add hydrochloric acid to adjust the pH to 3, heat and concentrate until precipitation occurs and stop, to obtain a concentrated solution;

[0023] 2) Filter the PA66 powder with a relative viscosity of 2.4, take particles with a particle size between 400 meshes, add it to the concentrated solution obtained in step 1), control the weight ratio of the concentrated solution and polyamide powder to be 10:1, and stir at 50°C While adding calcium formate powder, the addition amount of calcium formate powder is 5 times of that in PA66 powder, stirring and reacting for 5h and then standing for filtration to obtain a solid reactant;

[0024] 3) drying the solid reactant obtained in step 2) at 60°C, and melting and granulating to obtain PA6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com