Electrode for supercapacitor and preparation method and application thereof

A technology for supercapacitors and electrodes, which is applied in the field of electrodes for supercapacitors and their preparation, can solve the problems of low energy density and difficult to satisfy, and achieve the effects of obvious effects, simple methods, and flexible and controllable preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method for an electrode for a supercapacitor, comprising the following steps:

[0038] S1. After mixing activated carbon, Super P and PVDF, add it to N-methylpyrrolidone (NMP) solvent, ball mill and stir to form a uniform electrode slurry, and coat the electrode slurry on the carbon-coated aluminum foil;

[0039] The mass ratio of the solute composed of activated carbon, Super P and PVDF to the N-methylpyrrolidone solvent is 1: (4-6), and the mass ratio of activated carbon, Super P and PVDF is (8-7): (1-2): 1. The speed of the ball mill stirring treatment is 300-400rpm.

[0040] The thickness of the carbon-coated aluminum foil is 15-20 microns, and the coating thickness of the electrode slurry on the carbon-coated aluminum foil is 150-200 microns.

[0041] S2. Put the coated carbon-coated aluminum foil into a blast oven to dry the solvent, then put it into a vacuum oven, take it out after drying, and roll it tightly on an electric double-roller machine to m...

Embodiment 1

[0053] Weigh 0.8 grams of activated carbon, 0.1 grams of Super P and 0.1 grams of PVDF, mix them in 3 milliliters of N-methylpyrrolidone (NMP) solvent, stir by ball milling at a speed of 300 rpm to form a uniform electrode slurry, and coat with a 100-micron spatula On 18 micron thick charcoal-coated aluminum foil;

[0054] Put the coated pole pieces into a blast oven and bake at 80°C for 3 hours, then put them in a vacuum oven and bake at 80°C for 12 hours, then take them out, put them on an electric roller machine and roll them tightly, the thickness of the rolls is 80% before rolling.

[0055] Put the electrode piece in the ALD vacuum chamber for Al 2 o 3 Deposit 20 cycles. The temperature is 120° C., 20 cycles, and the deposition thickness is 2 nm.

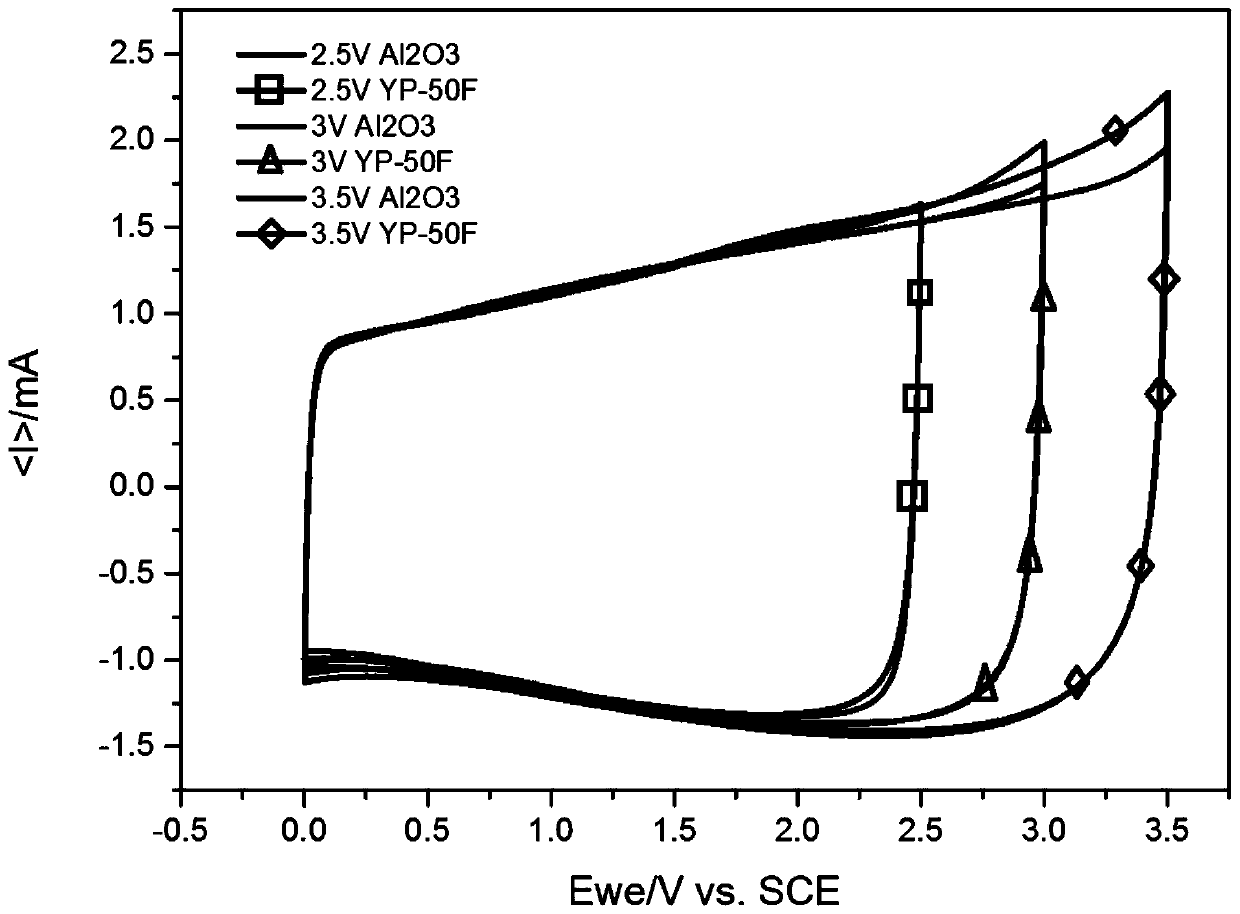

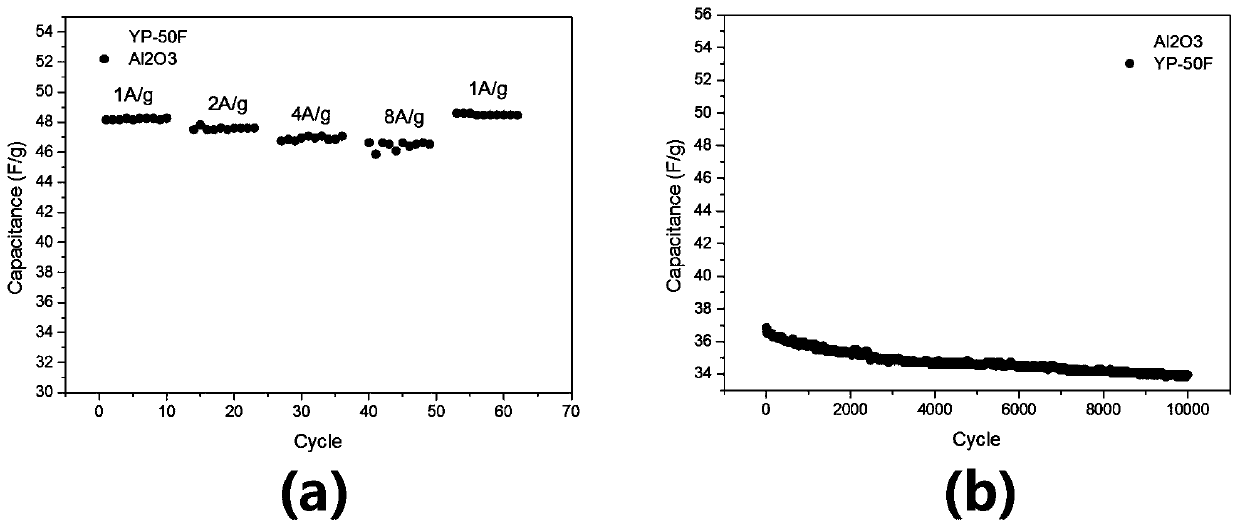

[0056] The above pole pieces were cut and assembled into batteries for electrochemical testing. The CV curve and the charge and discharge test results are as follows: figure 1 and figure 2 shown.

Embodiment 2

[0058] Weigh 0.8 grams of activated carbon, 0.1 grams of Super P and 0.1 grams of PVDF, mix them in 3.5 milliliters of N-methylpyrrolidone (NMP) solvent, and stir at 400 rpm to form a uniform electrode slurry by ball milling. 15 micron thick carbon-coated aluminum foil;

[0059] Put the coated pole piece in a blast oven at 100°C for 2 hours, then put it in a vacuum oven at 70°C for 12 hours, take it out, put it on an electric counter-roller and roll it tightly, and set the thickness to unrolled 90% of the time;

[0060] Put the electrode piece in the ALD vacuum chamber for Al 2 o 3 deposition. Temperature 100°C, 60 cycles, deposition thickness 6 nm;

[0061] The above-mentioned treated electrode pieces were cut and assembled into batteries for electrochemical testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com