Method for synthesizing boron-silicon and iron-silicon MTT zeolite in absence of organic structure directing agent

A technology of organic structure and directing agent, applied in the direction of crystalline aluminosilicate zeolite, iron silicate, inorganic chemistry, etc., can solve the problems of increased cost, waste liquid, exhaust gas emission, etc. The effect of purity, good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of solid ferrosilicon precursor

[0028] First, dissolve 0.2 g NaOH in 3 g H 2 O, then this solution was added dropwise to 30 g of aqueous silica sol with a mass fraction of 40% under stirring conditions. Then, ferric nitrate solution (dissolving a certain amount of ferric nitrate nonahydrate in 10gH 2 O) was added dropwise to the above solution. Then, the solution was stirred for another 2 h, and placed in an oven at 150° C. for 12 h to evaporate the water in the solution. In this way, solid ferrosilicon precursors can be obtained. In this solution, the masses of ferric nitrate nonahydrate added were 0.4g, 0.8g, and 8g respectively. Therefore, the Si / Fe molar ratios of the obtained solid ferrosilicon precursors are 200, 100, and 10, respectively.

Embodiment 2

[0029] Embodiment 2: Preparation of solid silicon boron precursor

[0030] First, dissolve 0.2 g NaOH in 3 g H 2 O, then this solution was added dropwise to 20 g of aqueous silica sol with a mass fraction of 40% under stirring conditions. Next, with sodium metaborate solution (a certain amount of sodium metaborate tetrahydrate is dissolved in 10g H 2 O) was added dropwise to the above solution. Then, the solution was stirred for another 2 h, and placed in an oven at 150° C. for 12 h to evaporate the water in the solution. In this way, a solid silicon-boron precursor can be obtained. In this solution, the masses of sodium metaborate tetrahydrate added were 0.09g, 0.61g, and 1.8g, respectively. Therefore, the Si / B molar ratios of the obtained solid silicon-boron precursors were 200, 30, and 10, respectively.

Embodiment 3

[0031] Embodiment 3: No organic structure directing agent method synthesis Fe-MTT zeolite

[0032] 1.56g solid ferrosilicon precursor (Si / Fe=100), 0.3g Na 2 SiO 3 9H 2 O, 1.9g ethanol and 0.16g all-silicon MTT (accounting for 10% of the mass ratio of solid precursor) seed crystals were placed in the grinding mill, and then crystallized at 140°C for 4 days to complete crystallization, and the product was suction filtered and dried get the product. The reaction raw material ratio is as follows:

[0033] SiO 2 :Fe:Na 2 O: ethanol = 1:0.01:0.04:1.5

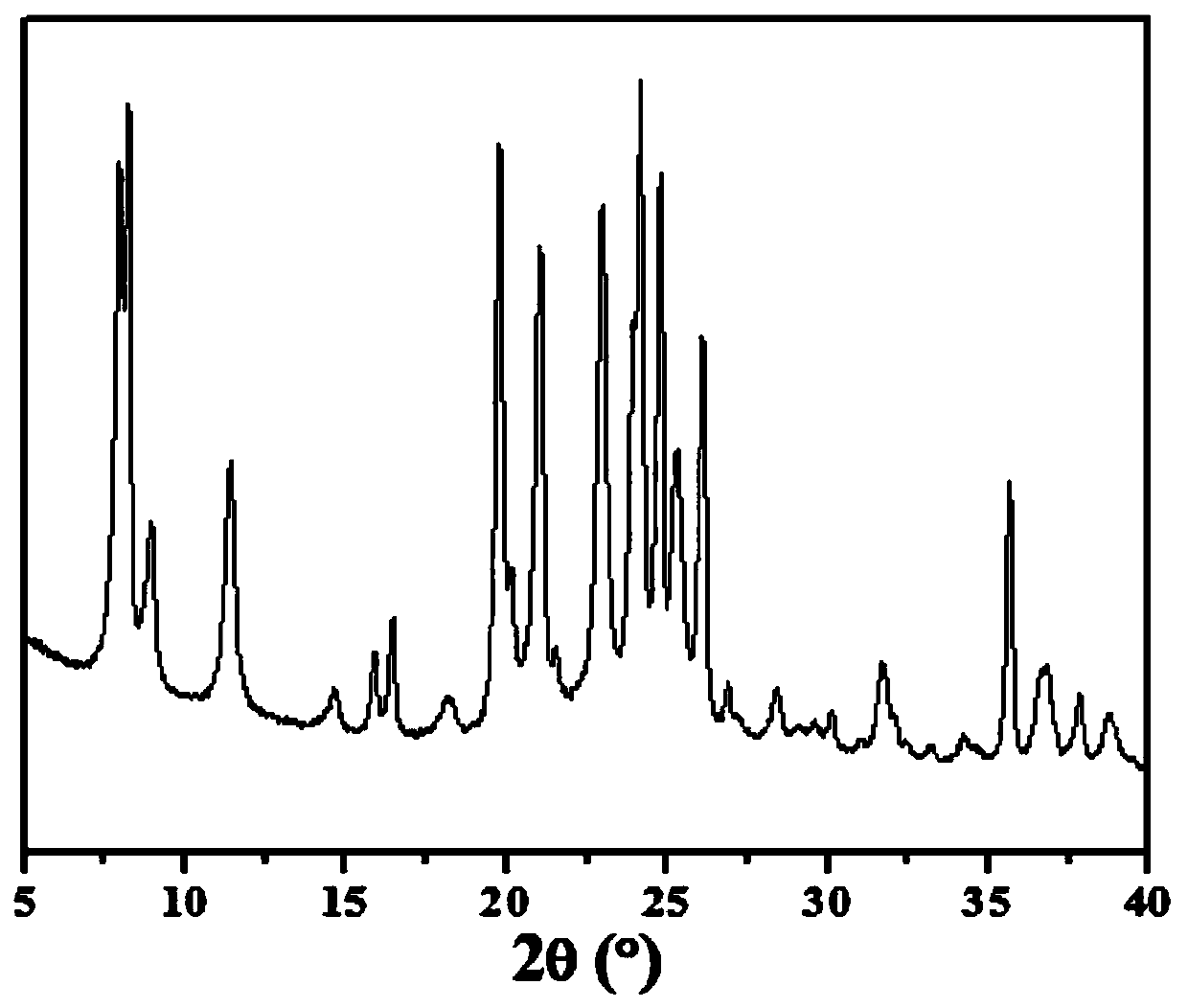

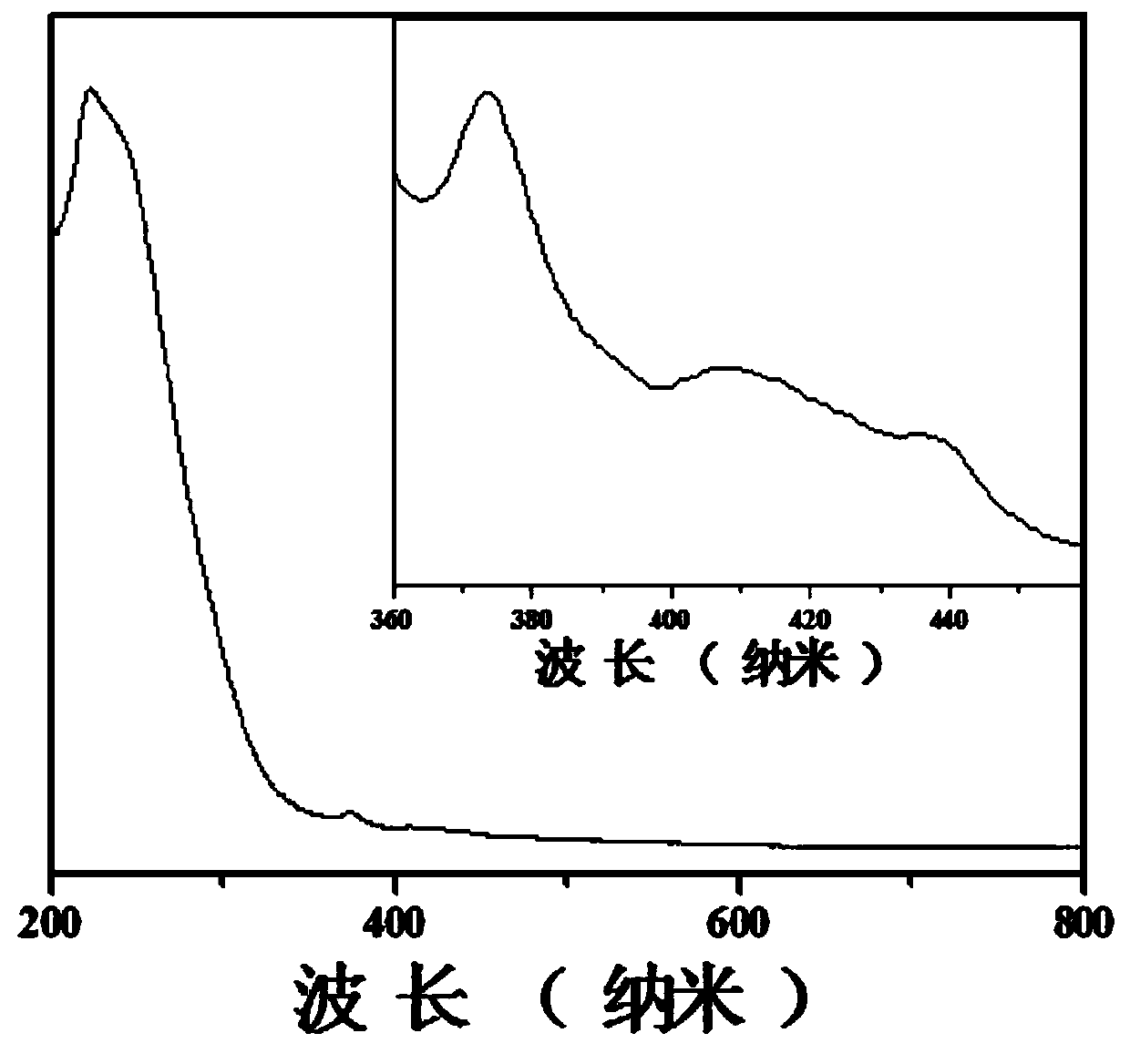

[0034] Through XRD analysis, its structure is MTT zeolite ( figure 1 ), and the Fe-MTT zeolite obtained by this method can be seen that its iron has entered the zeolite framework ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com