Stirring type environment-friendly electroplating wastewater precipitation treatment device

A technology for electroplating wastewater and sedimentation treatment, which is applied in the fields of metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. High-efficiency mixing, increased precipitation processing capacity, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

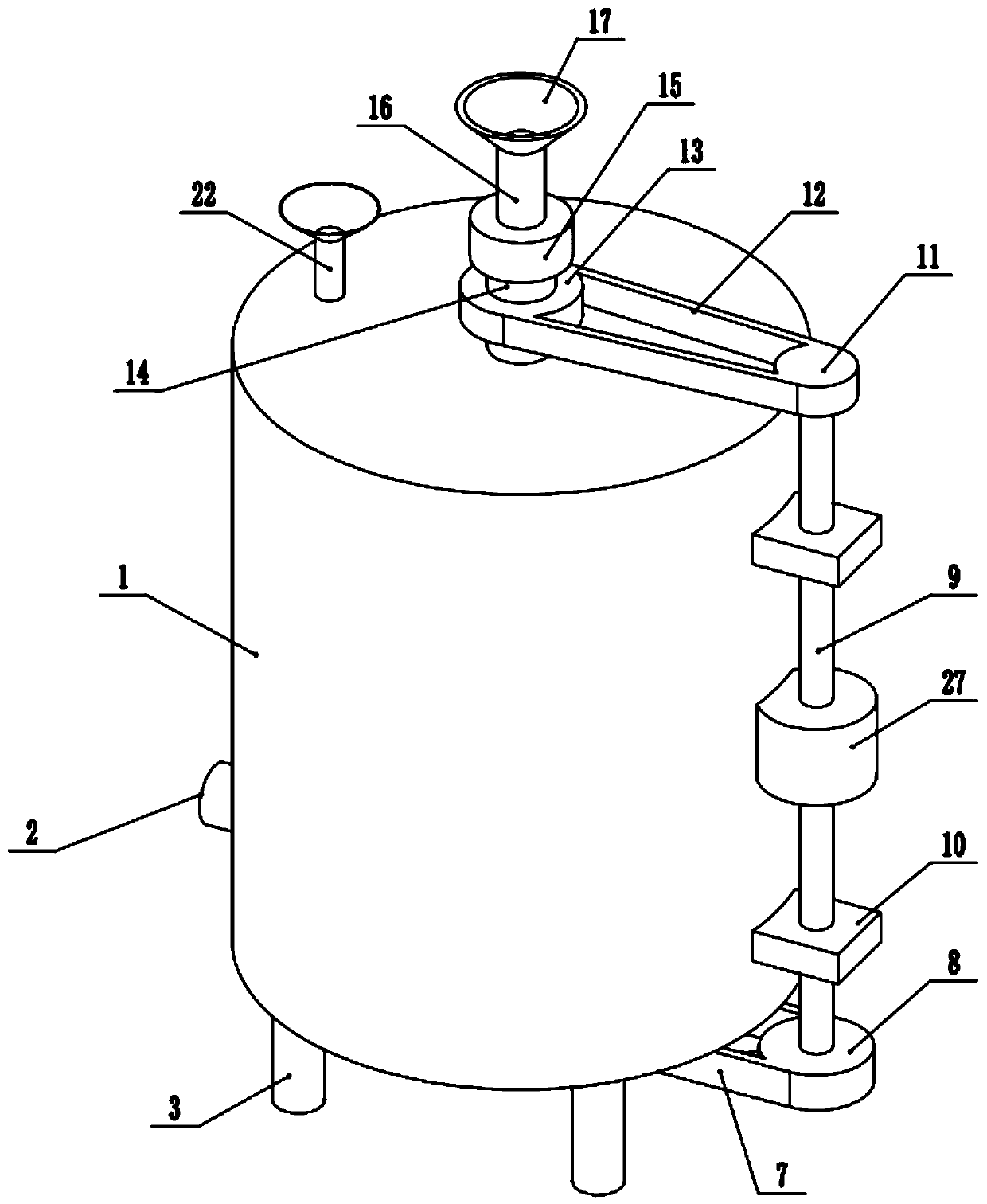

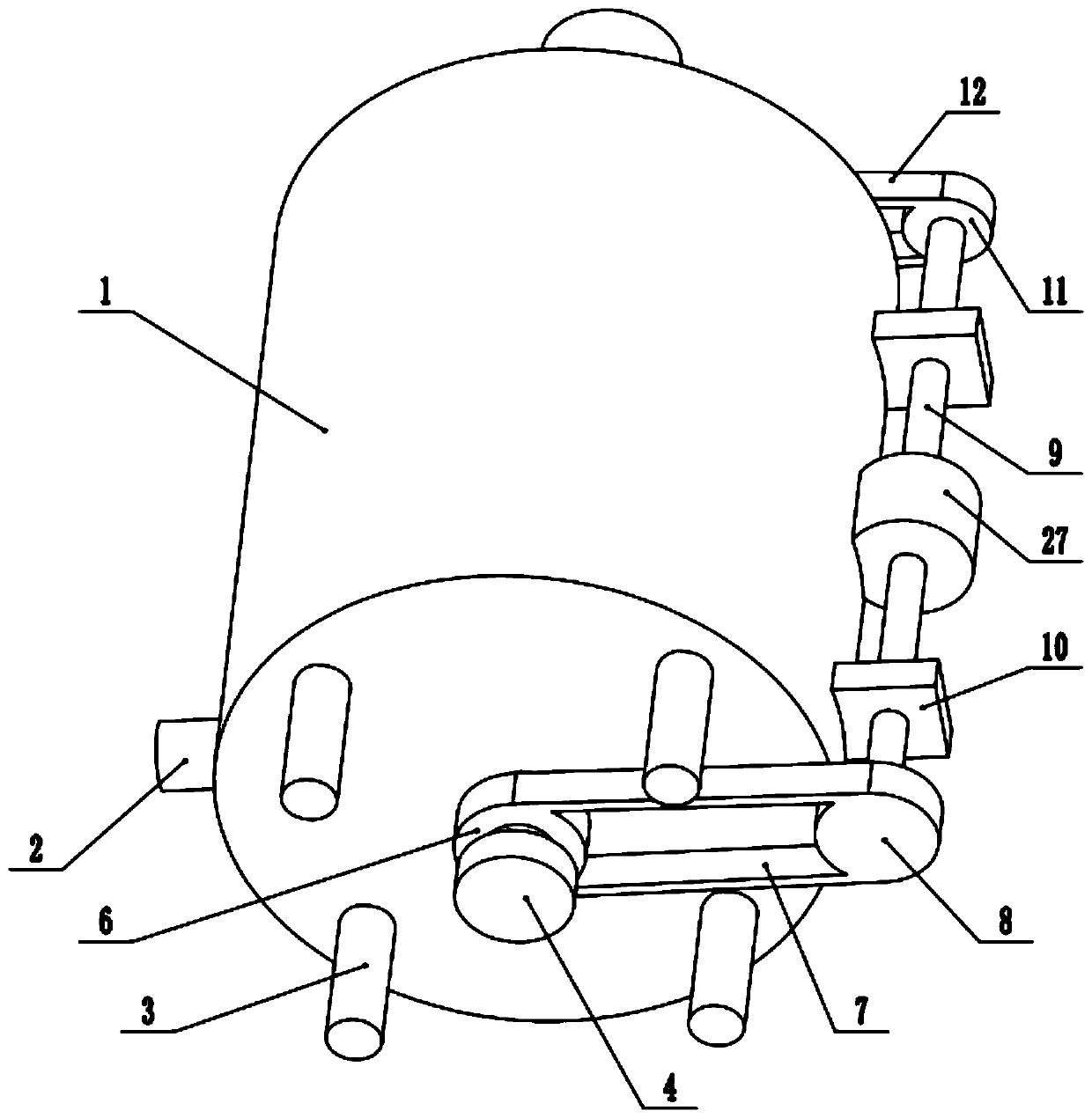

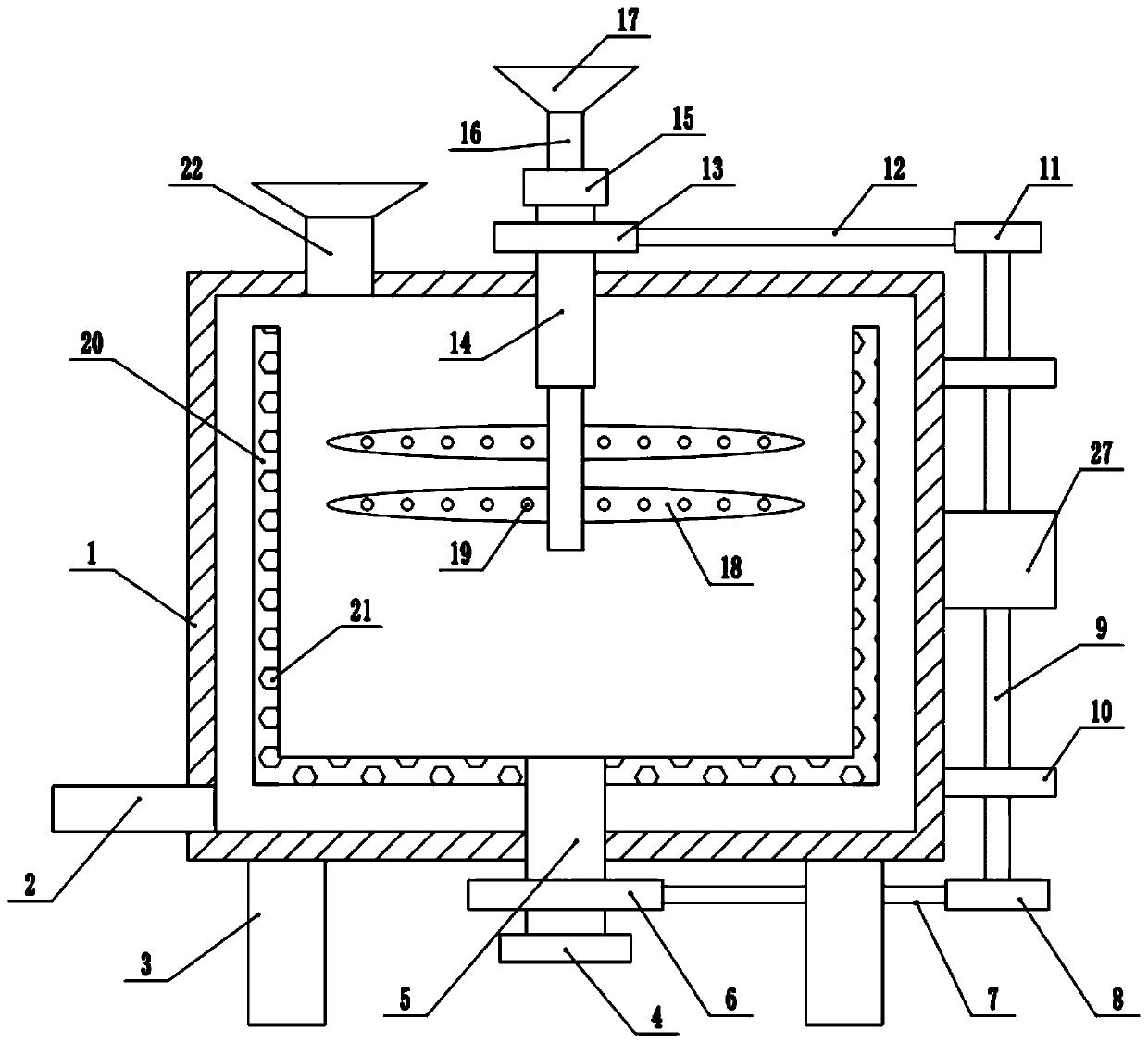

[0033] refer to Figure 1-7, in an embodiment of the present invention, a stirring environment-friendly electroplating wastewater precipitation treatment device includes a stirring box 1, and a drain pipe 2 is installed at the lower left side of the stirring box 1 for the non-precipitating liquid layer generated during the precipitation process The liquid in the mixing box 1 is discharged, and the four corners of the bottom of the mixing box 1 are equipped with support legs 3, which are used to support and fix the mixing box 1. The inside of the mixing box 1 is equipped with an isolation cylinder 20, and the inner wall of the isolation cylinder 20 is uniformly provided with a number of discharge holes. 21. By setting discharge holes 21 on the isolation cylinder 20, the water attached to the sediment inside the isolation cylinder 20 can be quickly discharged under the action of centrifugal force. The bottom end of the isolation cylinder 20 is equipped with a rotating shaft 5, an...

Embodiment 2

[0035] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the upper end of the stirring box 1 is installed on the left side and a feed hopper 22 is also installed for the introduction of electroplating waste water. By setting the feed hopper 22 can separate the electroplating waste water and the flocculant into the introduction channel inside the stirring tank 1, avoiding precipitation on the inner wall of the feeding hopper 17, and increasing the reliability of the whole device.

[0036] In the present invention, when in use, electroplating wastewater and flocculants are introduced into the inside of the stirring tank 1 through the feed hopper 22 and the feeding hopper 17, and then the biaxial motor 27 is started to make the stirring shaft 16 and the rotating shaft 5 rotate accordingly, so that The internal electroplating wastewater can be precipitated and stirred. During this process, we can adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com