Nanogel polymerized aluminum type liquid alkali-free accelerator and preparation method thereof

A technology of nano-gel and polymerized aluminum, which is applied in the field of concrete admixtures, can solve the problems of low early strength, safe use of fluorine-containing toxic substances, etc., and achieve the effect of improving stability, long-term stability, and early strength of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

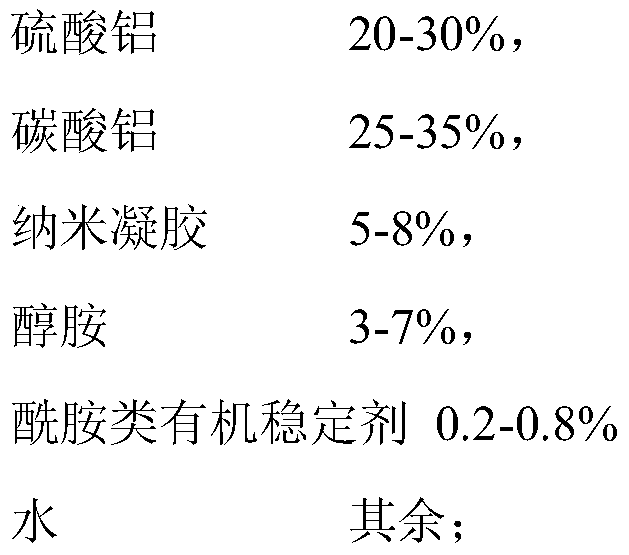

Method used

Image

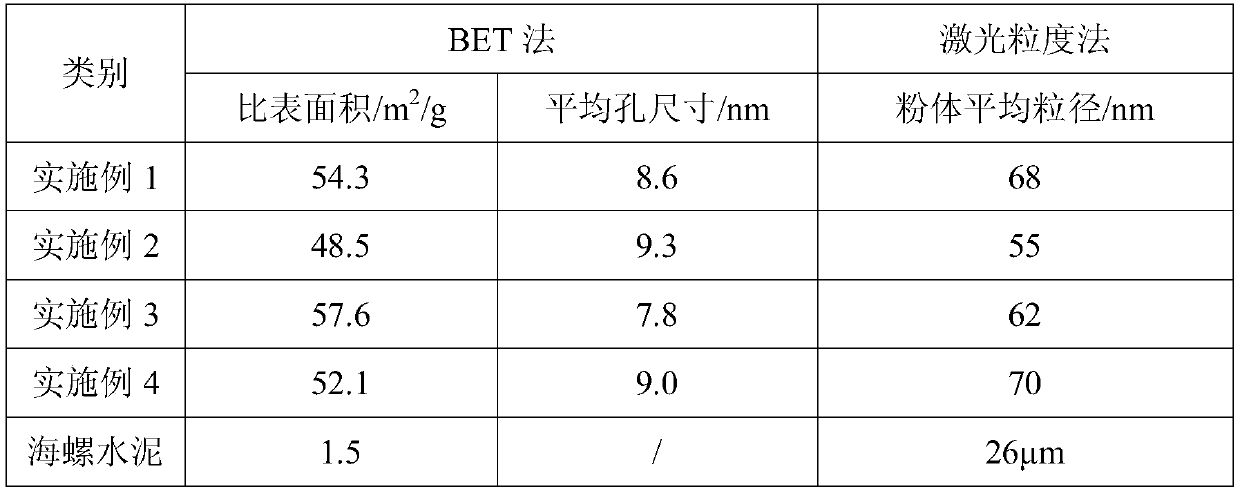

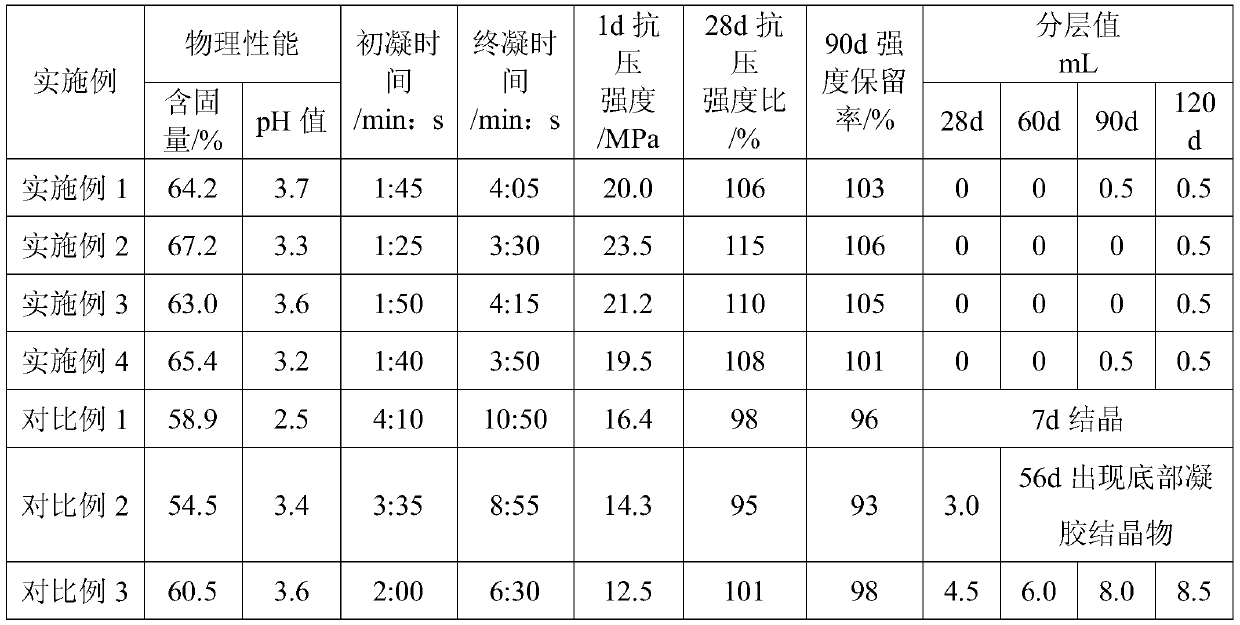

Examples

Embodiment 1

[0030] A preparation method of nano-gel polymerized aluminum type liquid alkali-free quick-setting agent, comprising the following steps:

[0031] (1) Add calcium oxide, white carbon black and water into a glass beaker with a calcium-silicon molar ratio of 1.8 and a water-solid ratio of 24 and stir thoroughly for 8 minutes, then perform ultrasonic dispersion for 5 minutes and then transfer the reaction materials to the reactor; according to the reaction temperature The hydrothermal synthesis reaction was carried out at 150°C and the reaction time was 8 hours. Finally, the reactant was centrifuged, filtered, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C to obtain nanogel;

[0032] (2) Mix 175g of aluminum carbonate, 30g of nanogel, 15g of diethanolamine and 147.5g of water evenly, stir while heating to 55°C, keep the temperature for 2.0h and let it stand for 0.5h to obtain the initial reactant; mix 130g of aluminum sulfate Add ...

Embodiment 2

[0034] A preparation method of nano-gel polymerized aluminum type liquid alkali-free quick-setting agent, comprising the following steps:

[0035] (1) Add calcium oxide, diatomaceous earth and water into a glass beaker with a calcium-silicon molar ratio of 1.5 and a water-solid ratio of 18 and stir thoroughly for 6 minutes, then ultrasonically disperse for 4 minutes and then transfer the reaction materials to the reactor; according to the reaction temperature The hydrothermal synthesis reaction was carried out at 120°C and the reaction time was 12 hours. Finally, the reactants were centrifuged, filtered, washed twice with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C to obtain nanogels;

[0036] (2) 150g of aluminum carbonate, 40g of nanogel, 20g of triethanolamine and 137g of water were mixed evenly, stirred while heating to 50°C, and left to stand for 0.5h after the insulation reaction for 1.5h to obtain the initial reactant; 150g of aluminum sulfat...

Embodiment 3

[0038] A preparation method of nano-gel polymerized aluminum type liquid alkali-free quick-setting agent, comprising the following steps:

[0039] (1) Add calcium oxide, diatomaceous earth and water into a glass beaker with a calcium-silicon molar ratio of 1.2 and a water-solid ratio of 15 and stir thoroughly for 10 minutes, then ultrasonically disperse for 3 minutes and then transfer the reaction materials to the reactor; according to the reaction temperature The hydrothermal synthesis reaction was carried out at 180°C and the reaction time was 6h. Finally, the reactants were centrifuged, filtered, washed twice with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C to obtain nanogels;

[0040] (2) Mix 175g of aluminum carbonate, 35g of nanogel, 30g of triisopropanolamine and 161g of water evenly, stir while heating to 60°C, keep the temperature for 1.5h and let it stand for 0.5h to obtain the initial reactant; Aluminum sulfate and 4g of polyacrylamide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com