Pyrolytic carbon black deep deashing process

A technology for pyrolysis of carbon and carbon black, applied in the field of harmless and resource utilization of garbage, can solve the problems of incomplete separation, large amount of acid and alkali, hidden safety hazards of acid method, etc., and achieves low equipment investment and operating costs, The effect of simplifying the process and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

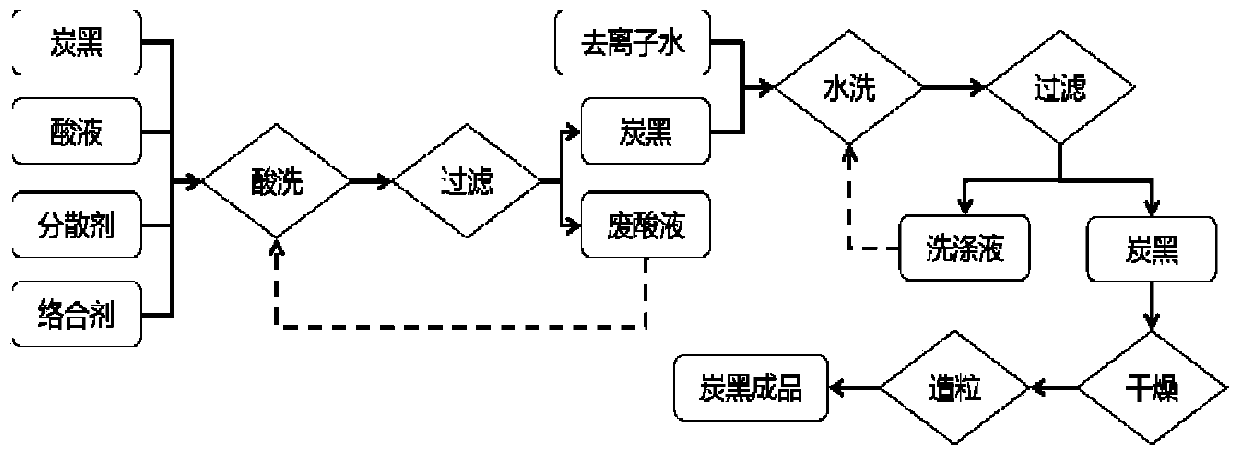

Image

Examples

Embodiment 1

[0035] 5g of pyrolytic carbon black, 50mL of HCl acid solution, 0.05g of sodium hexametaphosphate, and 0.5g of citric acid were mixed and added into the reactor, heated to 50°C in a water bath in a 40kHz ultrasonic vibration environment, and reacted for 120min. Ionized water is prepared according to 1:1 (v:v). After the reaction, it was separated by suction filtration to obtain a solid filter residue and a filtrate. The solid filter residue was washed repeatedly with deionized water, and the filter residue and washing liquid were separated by suction filtration. Until the washing solution turns neutral, stop the washing process, dry and granulate, and make carbon black finished products. The ash content of the prepared carbon black is reduced from the initial 18.1% to 5.6%

Embodiment 2

[0037] Mix 5g pyrolytic carbon black with 50mL HCl acid solution, 0.05g sodium hexametaphosphate, and 0.5g disodium EDTA into the reactor, heat it in a water bath to 50°C in a 40kHz ultrasonic vibration environment and react for 120min, in which the acid solution is composed of concentrated hydrochloric acid and Deionized water is prepared according to 1:1 (v:v). After the reaction, it was separated by suction filtration. A solid residue and filtrate were obtained. The solid filter residue was washed repeatedly with deionized water, and the filter residue and washing liquid were separated by suction filtration. Until the washing solution turns neutral, stop the washing process, dry and granulate, and make carbon black finished products. The ash content of the prepared carbon black decreased from the initial 18.1% to 5.1%.

Embodiment 3

[0039] Mix 5g pyrolytic carbon black with 75mL HCl acid solution, 0.05g sodium hexametaphosphate, and 0.5g disodium EDTA into the reactor, and heat it in a water bath to 50°C for 120min in a 40kHz ultrasonic vibration environment. The acid solution is composed of concentrated hydrochloric acid and Deionized water is prepared according to 1:1 (v:v). After the reaction, it was separated by suction filtration. A solid residue and filtrate were obtained. The solid filter residue was washed repeatedly with deionized water, and the filter residue and washing liquid were separated by suction filtration. Until the washing solution turns neutral, stop the washing process, dry and granulate, and make carbon black finished products. The ash content of the prepared carbon black decreased from the initial 18.1% to 4.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com