Single-component conductive adhesive stored and cured at normal temperature as well as preparation method and application thereof

A conductive adhesive, one-component technology, applied in the field of conductive adhesive, can solve problems such as dispensing, thickening, and repeated use, and achieve excellent moisture and heat aging resistance and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

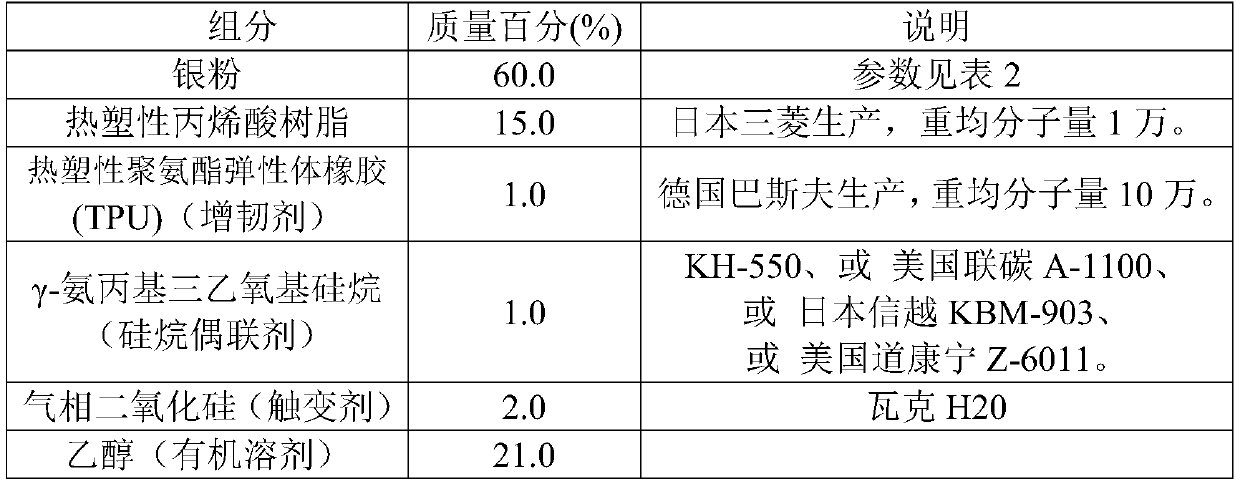

[0033] A single-component conductive adhesive stored and cured at room temperature, its raw material composition is shown in Tables 1 and 2:

[0034] Table 1

[0035]

[0036] Table 2

[0037]

[0038] Put thermoplastic acrylic resin, thermoplastic polyurethane elastomer rubber (TPU) toughening agent, silane coupling agent, thixotropic agent and organic solvent into the double planetary mixer (Taiyi (Shanghai) Industrial Co., Ltd., the model is TSJ-5) in the stainless steel kettle, open the cooling water, stirring and high-speed dispersion in sequence. Control the temperature and flow rate of the cooling water to keep the material temperature in the kettle not exceeding 30°C (the temperature and flow rate of the cooling water should be adjusted according to the actual temperature in the kettle. , to ensure that the temperature of the material in the kettle does not exceed 30°C), until the material is completely dissolved. Then add silver powder and continue to stir and ...

Embodiment 2

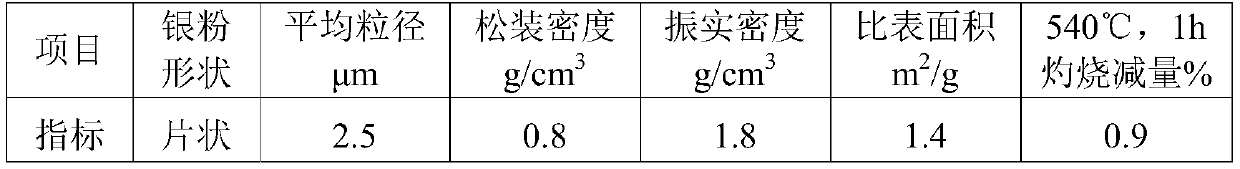

[0040] A single-component conductive adhesive stored and cured at room temperature, its raw material composition is shown in Table 3 and Table 4:

[0041] table 3

[0042]

[0043] Table 4

[0044]

[0045] Put thermoplastic acrylic resin, urethane (TPU) toughening agent, silane coupling agent, thixotropic agent and organic solvent into the stainless steel kettle of the double planetary mixer according to the weight ratio described in the above table 1, and open in sequence Cooling water, stirring and high-speed dispersion. Control the temperature and flow rate of the cooling water to keep the temperature of the material in the kettle not exceeding 30°C until the material is completely dissolved. Then add silver powder and continue to stir and disperse at high speed until the mixture is even. Then vacuumize and defoam, filter with 400-mesh steel mesh, then pack into syringes, and finally store in a dry and ventilated environment at room temperature.

Embodiment 3

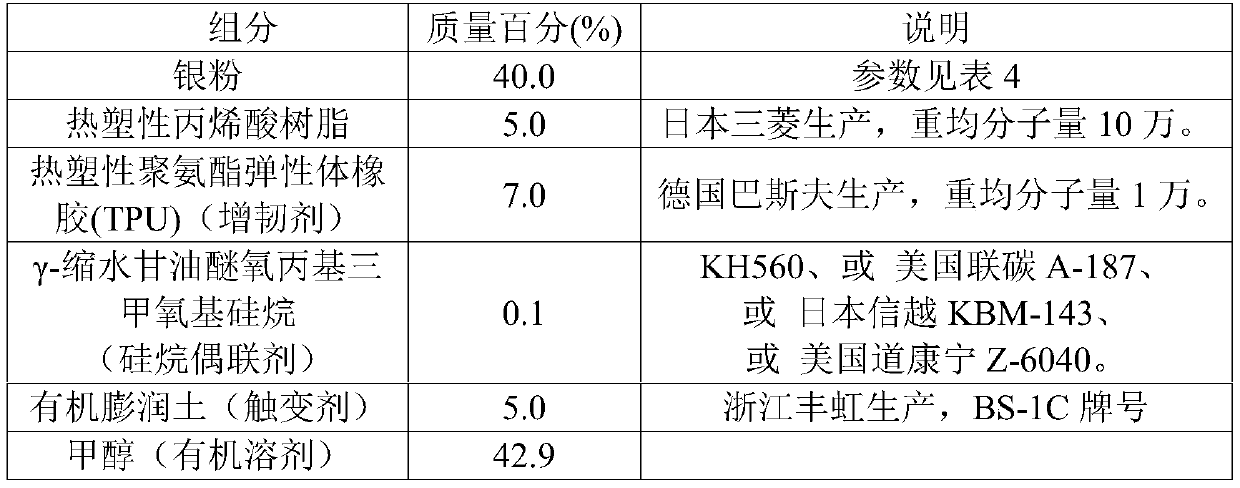

[0047] A single-component conductive adhesive stored and cured at room temperature, its raw material composition is shown in Table 5 and Table 6:

[0048] table 5

[0049]

[0050] Table 6

[0051]

[0052] Put thermoplastic acrylic resin, urethane (TPU) toughening agent, silane coupling agent, thixotropic agent and organic solvent into the stainless steel kettle of the double planetary mixer according to the weight ratio described in the above table 1, and open in sequence Cooling water, stirring and high-speed dispersion. Control the temperature and flow rate of the cooling water to keep the temperature of the material in the kettle not exceeding 30°C until the material is completely dissolved. Then add silver powder and continue to stir and disperse at high speed until the mixture is even. Then vacuumize and defoam, filter with 400-mesh steel mesh, then pack into syringes, and finally store in a dry and ventilated environment at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com