Method for preparing farnesene by cellulose, and engineering strain

A technology for engineering strains and engineering bacteria, which can be applied in the field of bioengineering and can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example is used to illustrate the preparation of cellulose hydrolyzate.

[0041] Weigh 100 g of corn stalks with a particle size of 20-80 meshes, add 1.5 L of formic acid solution (containing 88 wt % formic acid and 1 wt % HCl) and place it in a treatment tank. After reacting in a constant temperature water bath at 65° C. for 3 h, the reaction slurry was separated from solid to liquid. The solid component is further treated with ammonia water, the treatment conditions are: the concentration of ammonia water is 15wt%, the volume of ammonia water per kilogram of solid component is 8 liters, the treatment temperature is 60° C. and the reaction time is 16 hours. After the reaction, the material is separated from the solid and liquid, the solid component is washed with distilled water to pH 6-7, and dried to obtain the pretreated solid material.

[0042] The pretreated solid material is subjected to enzymatic hydrolysis, and the enzymatic hydrolysis conditions include:...

Embodiment 2

[0044] This example is used to illustrate the sequence structure of the plasmid. The commercially available vectors used in this example include the pet-22b vector, pBAD33 vector, pACYDCDuet-1 vector, pBBR1MCS-4 vector and pet-28a vector for knocking in the acetate kinase ack (gene) into the E. coli genome .

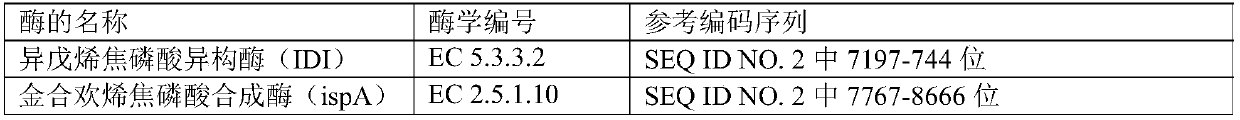

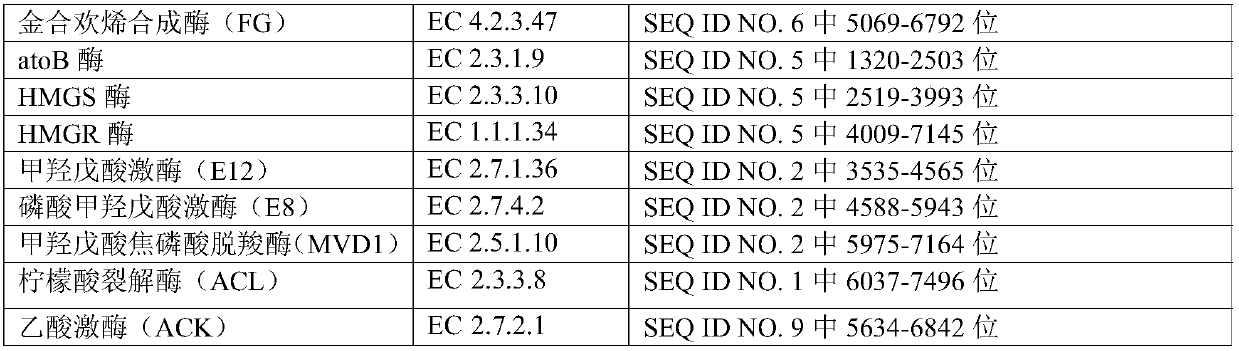

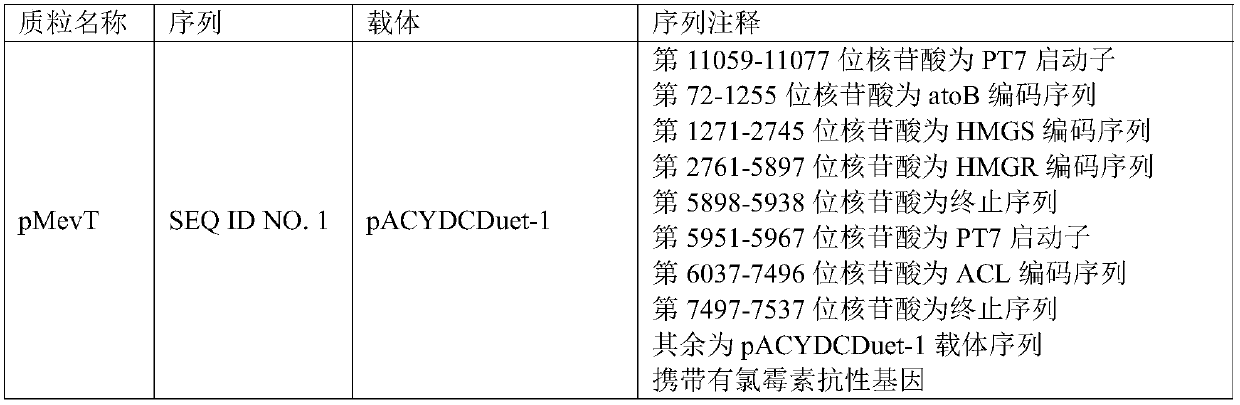

[0045] According to the instruction manual of the above-mentioned vectors, a set of plasmids for the metabolic pathway of MVA was constructed by using molecular biology operations such as PCR cloning, whole gene synthesis, restriction endonuclease digestion and ligation, including pMevT plasmid, pMBIS plasmid and pFII plasmid, and then One plasmid for replacing the pFII plasmid, ie, the pFG plasmid, was constructed, followed by two plasmids for replacing the pMevT plasmid, pMevT-1 and pMevT-2, respectively. The sequence information of the above plasmids is specifically shown in Table 2.

[0046] Table 2

[0047]

[0048]

[0049]

Embodiment 3

[0051] This example is used to illustrate the construction process of engineering strains.

[0052] Construction of the engineering strain F1 of the experimental group: Escherichia coli BL21 was selected as the host cell, and acetate kinase (ack) was knocked in according to the following method to obtain a strain overexpressing acetate kinase (ack) after knocking in.

[0053] The first step of competent cell preparation: After the plasmid pREDKI (shown in SEQ ID NO.10) was transferred into Escherichia coli BL21, it was inoculated into LB liquid medium (kana resistance), and placed in a shaker at 30°C overnight, The next day, they were transferred to fresh LB liquid medium (kana resistance) at a volume ratio of 1:100, cultured at 30°C until the OD600 was between 0.2 and 0.3, and induced by adding L-arabinose at a final concentration of 10 mmol / L. After induction for 1-1.5 hours, remove the ice bath from the shaker at 30°C for more than 10 minutes, centrifuge at 3500rpm / min at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com