Method for protecting thin-wall energy gathering cutting ropes by using Parylene micro-nano films

A cutting wire, micro-nano technology, applied in metal material coating process, coating, gaseous chemical plating, etc. The wall pipe is prone to corrosion and other problems, so that the composition of the film is easy to control, the step coverage is excellent, and the effect of meeting the protection requirements is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

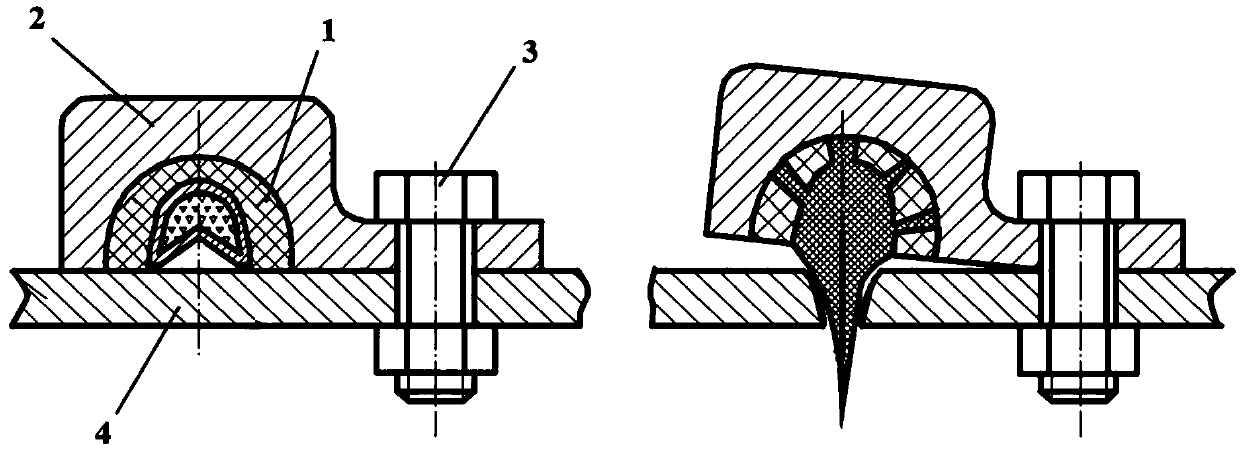

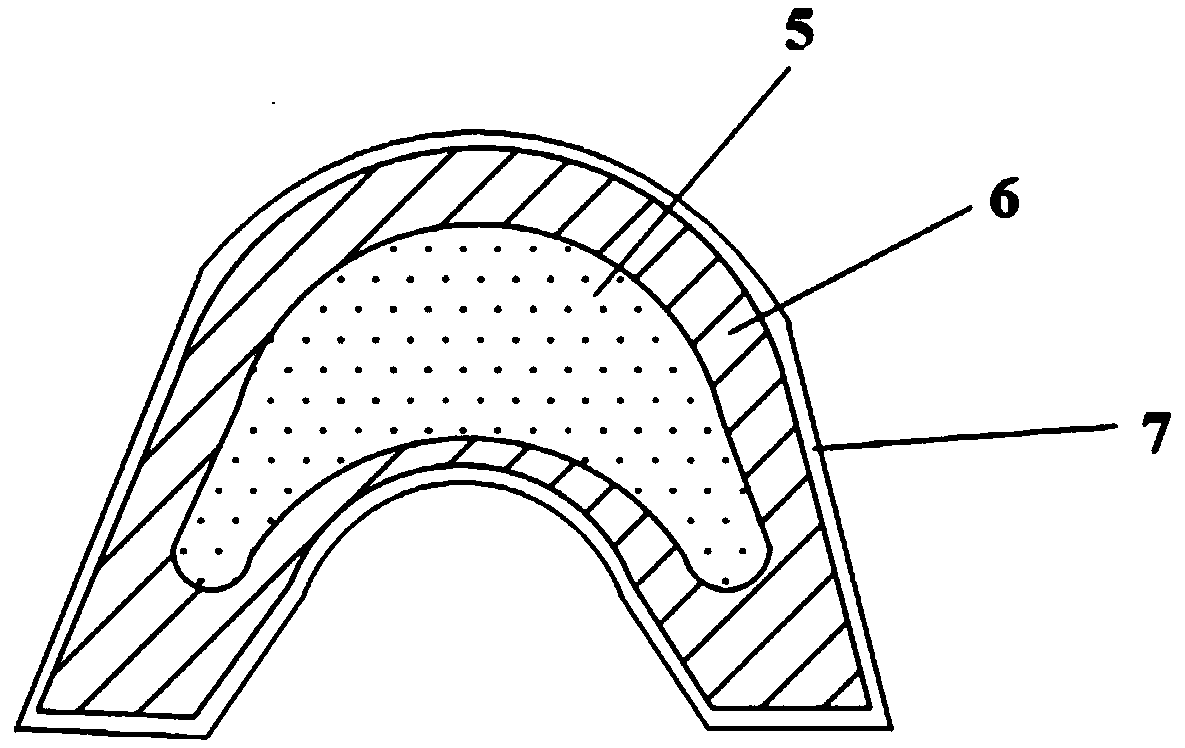

[0029] Protection of Thin-Walled Lead Pipe Cutting Cables Using Parylene C

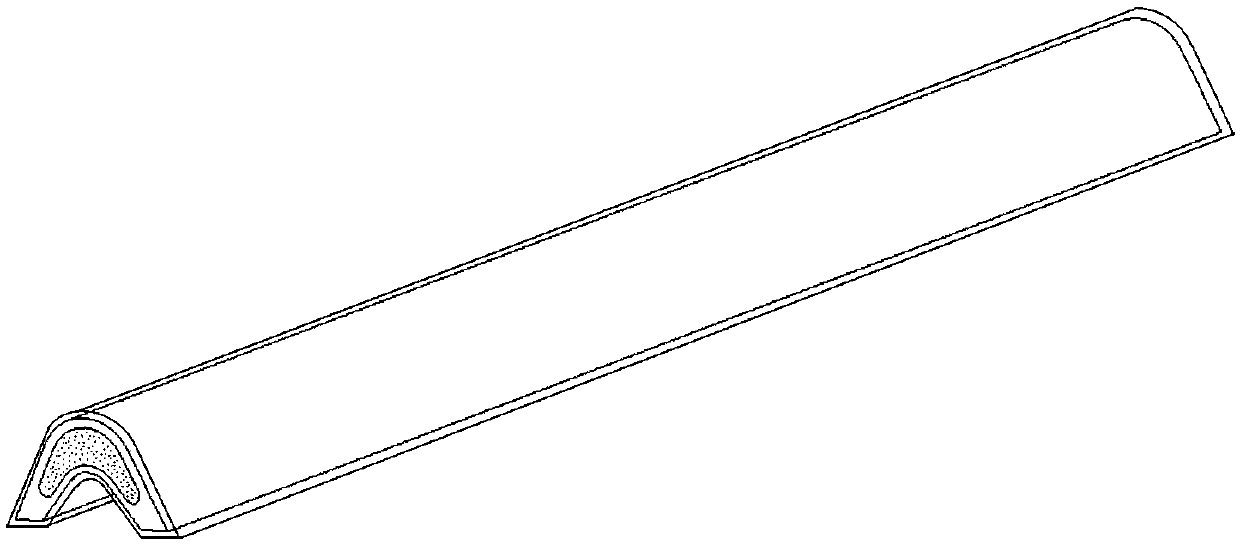

[0030] Cut the thin-walled lead-antimony alloy (with an antimony content of 2%) with a length of 10 m into a ring shape and put it into a vacuum chamber of a chemical vapor deposition device. It should be noted that the filament should be suspended in the vacuum chamber, and its diameter is about tens of microns, so that the thin-walled cutting wire is suspended on the filament, and there is no mutual contact between each ring, such as Figure 4 shown. When the vacuum in the chamber is lower than 2.0×10 -2 At torr, evaporate at 180°C, crack Parylene C raw material at 700°C, cool down at the end of the equipment through a cold trap, keep the temperature in the vacuum deposition chamber at about 35°C, and finally cut the cable of Parylene C monomer in the thin-walled lead pipe Polymerization occurs on the outer wall, which is about 25 μm thick. After a series of environmental assessment tests, the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com