Power plant sterilization algicide and preparation method thereof

A bactericidal and algicide technology for power plants, applied in the directions of fungicides, herbicides and algicides, botanical equipment and methods, etc. problem, to achieve the effect of good compounding effect of reagents, stable transportation and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a power plant bactericidal algicide is characterized in that it comprises the following steps:

[0023] (1) The weight ratio is 1% of trimethylamine, 0.1% of oxychloropropane, 25% of 12 / 14 tertiary amine, the quaternary tetrakis hydroxymethyl phosphorus sulfate, and its mass ratio is 1:1.2-1.8, 1%, isothiazole Phosphoketone 03%, stirring;

[0024] (2) Place 1% hydrochloric acid and remainder deionized water in the uniformly stirred product described in step (1), so that its pH value is 7.

[0025] (3) inspection canning of the product obtained in step (2).

Embodiment 2

[0027] A preparation method of a power plant bactericidal algicide is characterized in that it comprises the following steps:

[0028] (1) The weight ratio is 25% of trimethylamine, 10% of chloropropane oxide, 10% of 12 / 14 tertiary amine, 1% of tetradecyl tributyl phosphorus chloride, and 10% of dodecyl tributyl phosphorus chloride , its mass ratio is 1:1.2, isothiazolone 4%, stirs;

[0029] (2) 4% hydrochloric acid and remainder deionized water are placed in the uniformly stirred product described in step (1), so that its pH value is 8.

[0030] (3) inspection canning of the product obtained in step (2)

Embodiment 3

[0032] A preparation method of a power plant bactericidal algicide is characterized in that it comprises the following steps:

[0033] (1) The weight ratio is 30% of trimethylamine, 15% of chloropropane oxide, 20% of 12 / 14 tertiary amine, 1-25% of dodecyl tributyl phosphorus chloride, 4% of isothiazolone, and carry out stir;

[0034] (2) Place 6% hydrochloric acid and remainder deionized water in the uniformly stirred product described in step (1), so that its pH value is 6.

[0035] (3) inspection canning of the product obtained in step (2).

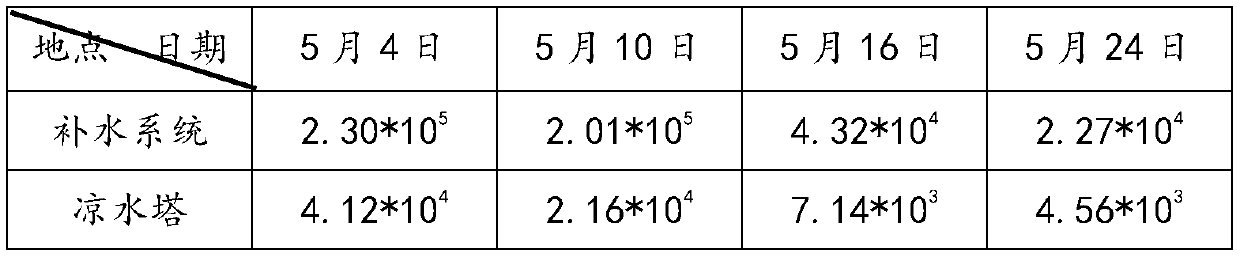

[0036] The power plant bactericidal algicide prepared in Example 1 is placed in different positions of the power plant, and the water quality is sampled at different time periods and different positions of the power plant. The results of the number of algae in the sampled product are as follows:

[0037] The number of algae at different time and different sampling points in the power plant (unit: piece / mL)

[0038]

[0039] As can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com