Preparation method and application of silicon dioxide/cellulose composite porous material

A technology of silica and porous materials, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of high cost, single source of cellulose, etc., achieve simple operation, high CO2 adsorption capacity, raw materials Inexpensive and easy-to-get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

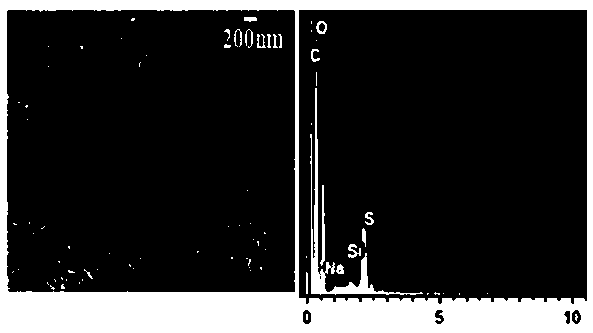

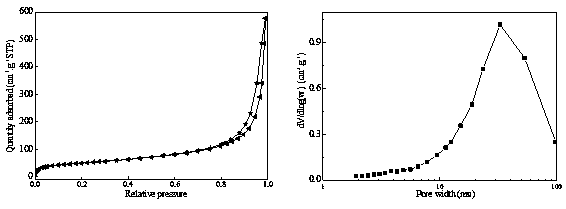

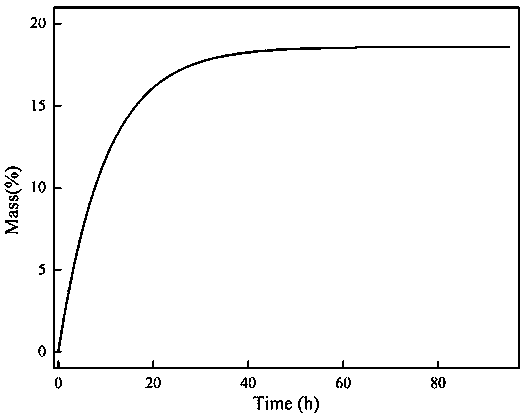

Embodiment 1

[0030] (1) Prepare fly ash-based silica wet gel, that is, mix fly ash and sodium carbonate evenly at a mass ratio of 1:1.2, place it at 800°C for 2 hours, take it out and cool it to room temperature, press The ratio of adding 8mL hydrochloric acid solution to 1g roasted product is to add 3mol / L hydrochloric acid solution to the roasted product while stirring, and after fully dissolving, filter, and place the filtrate at 90°C for sol-gel for 2 hours, and add 20 mL of hydrochloric acid solution with a concentration of 1 mol / L, ultrasonicated for 5 minutes, suction filtered, and washed repeatedly with deionized water until neutral, and the fly ash-based silica wet gel was obtained;

[0031] (2019).CO 2 The method in capture performance and characterization of cellulose aerogels synthesized from old corrugated containers. CarbohydrPolym, 115380. extracts cellulose from waste corrugated paper;

[0032](3) Put fly ash-based silica wet gel and old corrugated paper-based cellulose...

Embodiment 2

[0038] (1) Prepare coal gangue-based silica wet gel, that is, mix coal gangue and sodium carbonate evenly at a mass ratio of 1:1.2, place it at 800°C for 2 hours, take it out and cool it to room temperature, and then roast it at 1 g Proportion of adding 8mL hydrochloric acid solution to the product. Add 3mol / L hydrochloric acid solution to the roasted product while stirring. After fully dissolving, filter the filtrate and place the filtrate at 90°C for sol-gel for 2 hours. Add 20mL concentration of It is a 1mol / L hydrochloric acid solution, ultrasonicated for 5 minutes, suction filtered, and washed repeatedly with deionized water until neutral, and the gangue-based silica wet gel is obtained;

[0039] (2) Extract cellulose from waste corrugated paper, the method is the same as in Example 1;

[0040] (3) Put coal gangue-based silica wet gel and old corrugated paper-based cellulose into a beaker at the same time, wherein the mass ratio of silica wet gel dry basis to cellulose dr...

Embodiment 3

[0046] (1) Prepare fly ash-based silica wet gel, that is, mix fly ash and sodium carbonate evenly at a mass ratio of 1:1.2, place it at 800°C for 2 hours, take it out and cool it to room temperature, press The ratio of adding 8mL hydrochloric acid solution to 1g roasted product is to add 3mol / L hydrochloric acid solution to the roasted product while stirring, and after fully dissolving, filter, and place the filtrate at 90°C for sol-gel for 2 hours, and add 20 mL of hydrochloric acid solution with a concentration of 1 mol / L, ultrasonicated for 5 minutes, suction filtered, and washed repeatedly with deionized water until neutral, and the fly ash-based silica wet gel was obtained;

[0047] (2) extract cellulose from waste newsprint, the method is the same as embodiment 1;

[0048] (3) Put fly ash-based silica wet gel and cellulose into a beaker at the same time, wherein the mass ratio of silica wet gel dry base to cellulose dry base is 2:1; then pour it into the beaker that has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com