Method for cleaning activated alumina balls in hydrogen peroxide production

A technology of activated alumina and hydrogen peroxide, applied in peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., can solve low cleaning efficiency, Affect production efficiency, low alumina activity and other issues, to achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

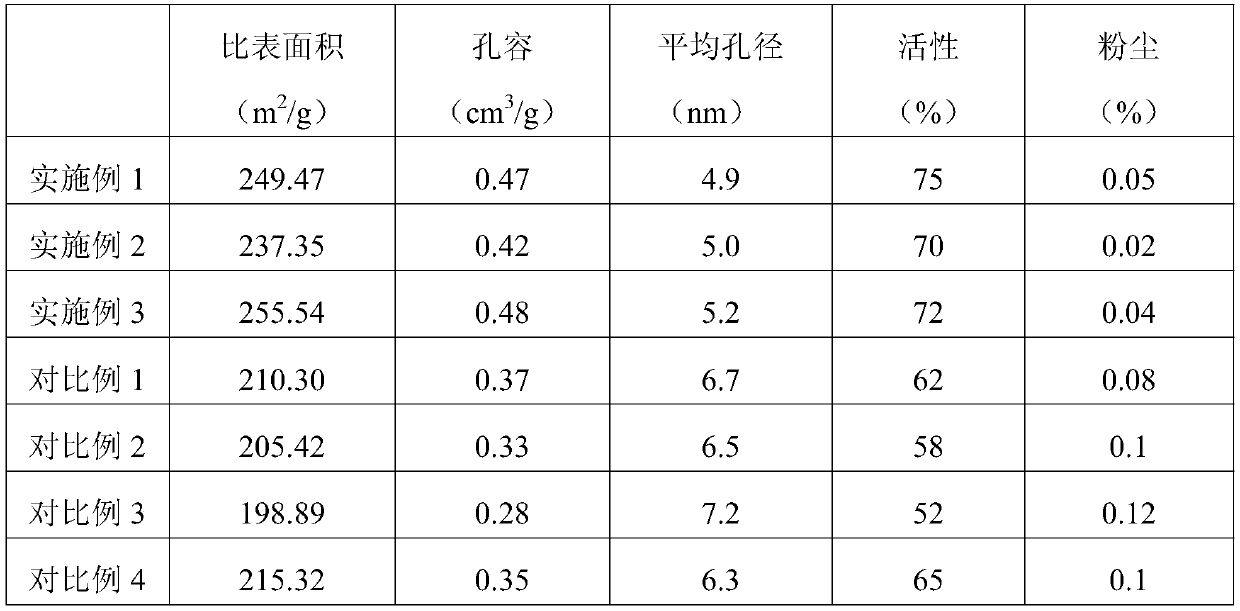

Examples

Embodiment 1

[0027] A kind of cleaning method of activated alumina ball in hydrogen peroxide production, comprises the following steps:

[0028] S1. Ethanol treatment

[0029] Wash the old activated alumina balls removed from hydrogen peroxide production with clean water and dry them; then stir the dried old activated alumina balls in 80% alkaline ethanol solution for 30 minutes, then take them out, wash them, and dry them .

[0030] The pH of the alkaline ethanol solution is 10. The pH of the alkaline ethanol solution was adjusted with sodium carbonate and glacial acetic acid.

[0031] S3. Steam treatment

[0032] Put the old activated alumina balls steam-treated in step S2 into a vacuum chamber to evacuate and maintain the pressure for 40 minutes, then pass high-temperature and high-pressure steam into the vacuum chamber, and heat-preserve and maintain the pressure at 120°C and 1Mpa for 2 hours.

[0033] S3. Ozone treatment

[0034] Dry the old activated alumina balls steam-treated ...

Embodiment 2

[0041] A kind of cleaning method of activated alumina ball in hydrogen peroxide production, comprises the following steps:

[0042] S1. Ethanol treatment

[0043] Wash the old activated alumina balls removed from the production of hydrogen peroxide with clean water and dry them; then stir the dried old activated alumina balls in 70% alkaline ethanol solution for 30 minutes, then take them out, wash them, and dry them .

[0044] The pH of the alkaline ethanol solution is 9. The pH of the alkaline ethanol solution was adjusted with sodium carbonate and glacial acetic acid.

[0045] S3. Steam treatment

[0046] Put the old activated alumina balls steam-treated in step S2 into a vacuum chamber to evacuate, and keep the pressure for 60 minutes, then pass high-temperature and high-pressure steam into the vacuum chamber, and heat-preserve and hold-pressure for 3 hours at 110°C and 2Mpa.

[0047] S3. Ozone treatment

[0048] Dry the old activated alumina balls steam-treated in st...

Embodiment 3

[0055] A kind of cleaning method of activated alumina ball in hydrogen peroxide production, comprises the following steps:

[0056] S1. Ethanol treatment

[0057] Wash the old activated alumina balls removed from the production of hydrogen peroxide with clean water and dry them; then stir the dried old activated alumina balls in 90% alkaline ethanol solution for 20 minutes, then take them out, wash them, and dry them .

[0058] The pH of the alkaline ethanol solution is 10. The pH of the alkaline ethanol solution was adjusted with sodium carbonate and glacial acetic acid.

[0059] S3. Steam treatment

[0060] Put the old activated alumina balls steam-treated in step S2 into a vacuum chamber to evacuate and keep the pressure for 20 minutes.

[0061] S3. Ozone treatment

[0062] Dry the old activated alumina balls steam-treated in step S2, and then pass through ozone for 1 hour. Ozone flow rate 3m3 / min.

[0063] S4. Calcination

[0064] Calcinate the old activated alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com