Environment-friendly cooling system sterilizing algicide

A technology of bactericidal and algaecide and cooling system, which is applied in the fields of sterilization/microdynamic water/sewage treatment, natural water treatment, special treatment targets, etc. Bacterial groups, weak peeling ability and other problems, to achieve the effect of promoting mutual coordination, improving sterilization effect, and enhancing peeling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An environment-friendly cooling system bactericide and algicide, comprising the following components:

[0062] Hydrogen peroxide 10kg; dioctyl sodium sulfosuccinate 5kg; polyaluminum ferric chloride 0.5kg; polyhexamethyleneguanidine 11kg; attapulgite 4kg; deionized water 20kg.

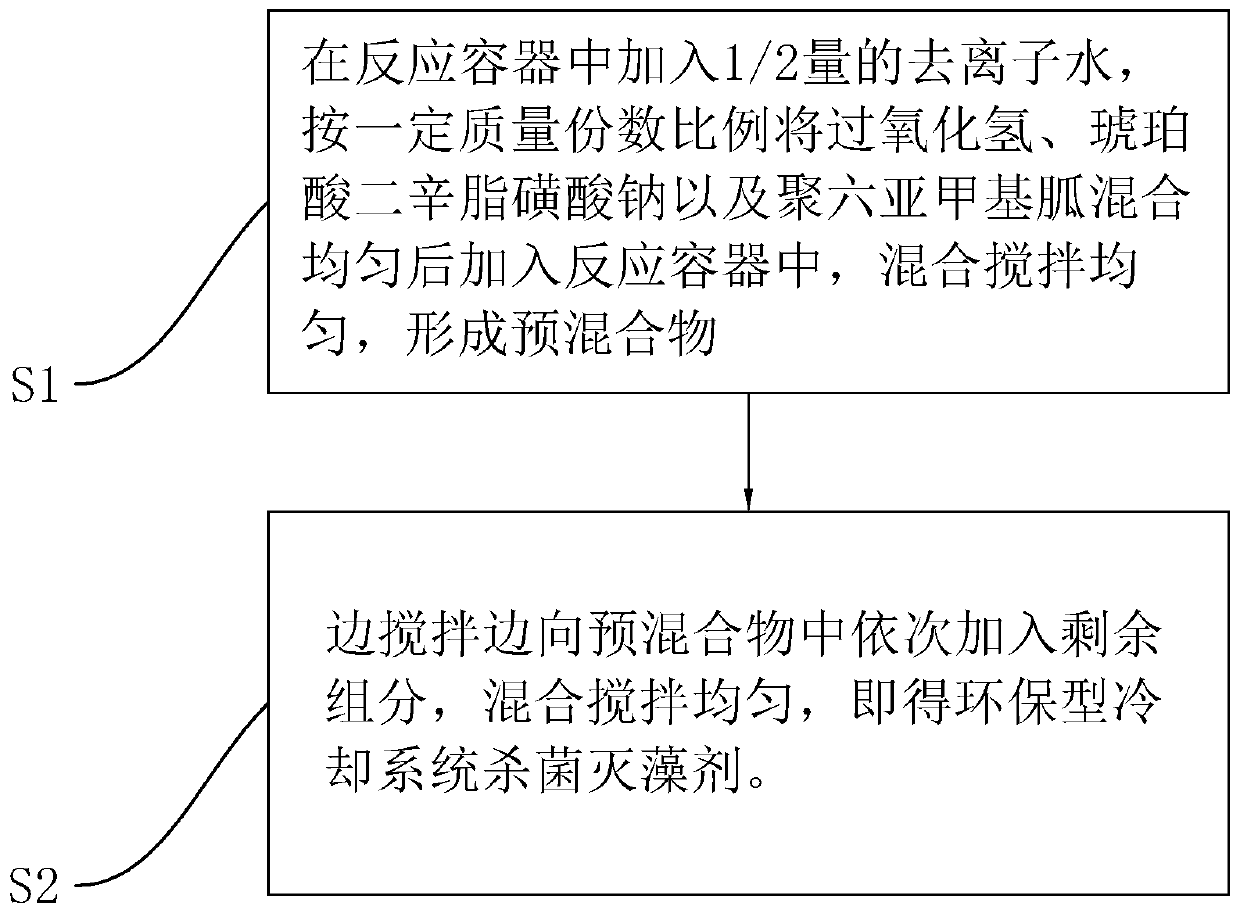

[0063] The preparation method of environment-friendly cooling system bactericidal algicide is as follows:

[0064] S1. In a 200L stirred tank, stir at a speed of 200r / min at room temperature, add 10kg of deionized water while stirring, mix 10kg of hydrogen peroxide, 5kg of dioctyl sodium sulfosuccinate, polyhexaethylene Add 11 kg of methylguanidine to the stirring tank after mixing evenly, mix and stir evenly to form a pre-mixture;

[0065] S2. Add 0.5 kg of polyaluminum ferric chloride, 4 kg of attapulgite, and 10 kg of deionized water to the premixture while stirring, and mix and stir evenly to obtain an environmentally friendly cooling system bactericide and algicide.

Embodiment 2

[0067] The difference with Example 1 is: 15kg of hydrogen peroxide is added in the stirred tank; 7kg of dioctyl sodium sulfosuccinate; 1.5kg of polyaluminum ferric chloride; 14kg of polyhexamethylene guanidine; 6kg of attapulgite; 30kg of water.

Embodiment 3

[0069] The difference with Example 1 is: 20kg of hydrogen peroxide is added in the stirred tank; Dioctyl sodium sulfosuccinate 10kg; Polyaluminum ferric chloride 3kg; Polyhexamethylene guanidine 18kg; Attapulgite 9kg; Deionized water 40kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com