Technology for preprocessing wastewater generated in dysprosium oxide production

A production wastewater and pretreatment technology, applied in mining wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems that restrict the development of the rare earth industry, difficult to meet the wastewater discharge requirements, etc., and achieve strong adsorption of small particles and metals The effect of ion power, strength increase, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

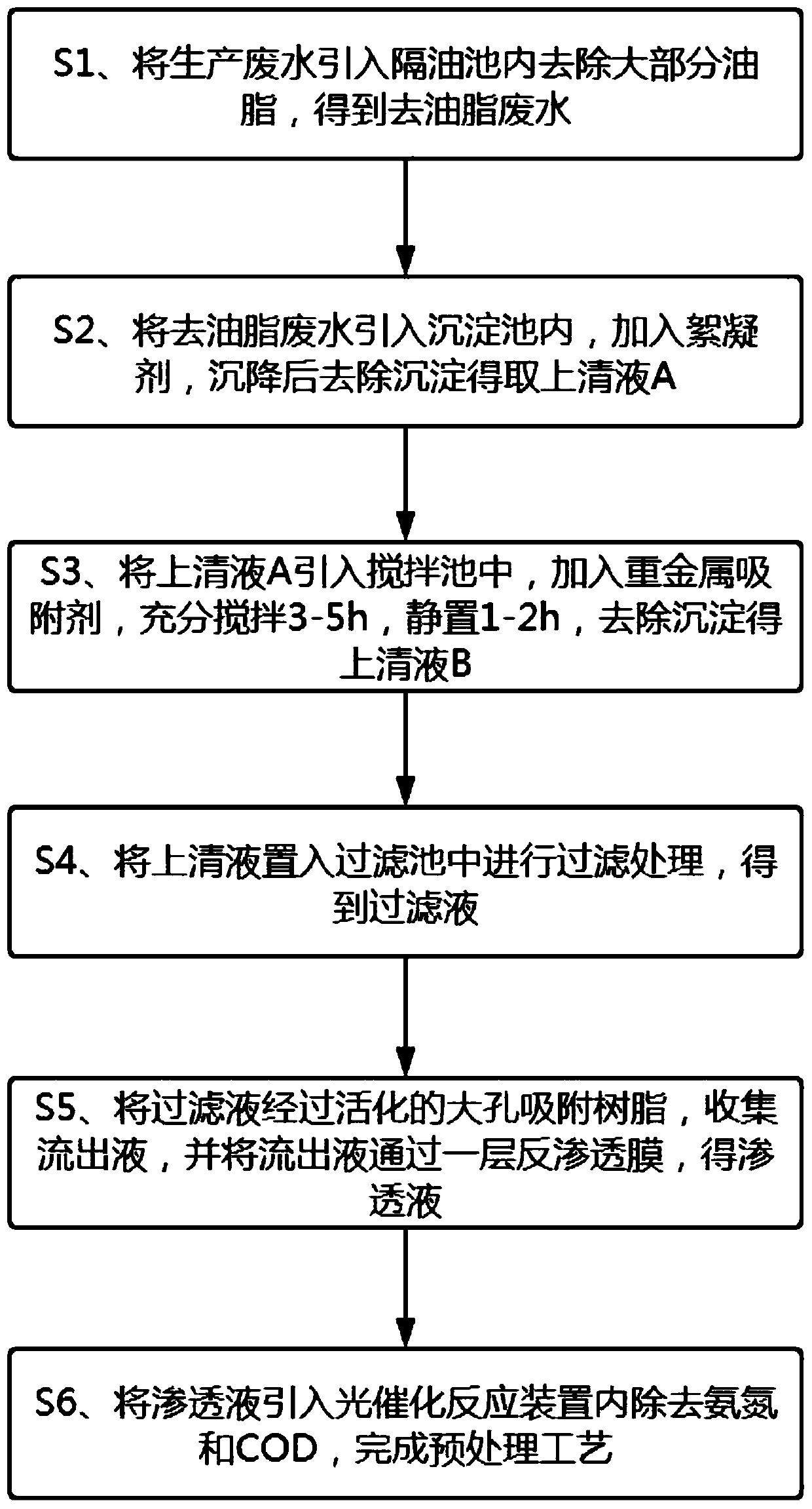

[0044] A kind of dysprosium oxide production wastewater pretreatment process, comprises the following steps:

[0045] S1. Introducing the production wastewater into the grease trap to remove most of the grease to obtain degreasing wastewater;

[0046] S2, introducing the degreasing wastewater into the sedimentation tank, adding a flocculant, and removing the sediment after settling to obtain the supernatant A;

[0047] In S2, the flocculant is polyacrylamide, aluminum sulfate, polyaluminum chloride or a mixture of two or more, the amount of flocculant is 0.25-1.0mg / L, and the settling time is 20-30min.

[0048] S3. Introduce the supernatant A into the stirring tank, add a heavy metal adsorbent, fully stir for 3-5 hours, let stand for 1-2 hours, and remove the precipitate to obtain the supernatant B;

[0049] In S3, the heavy metal adsorbent includes the following components by weight: 10-15 parts of solidified mixture, 4-8 parts of lignin, 3-6 parts of diatomaceous earth, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com