Yttrium iron garnet ferrite material and preparation method thereof

A technology of yttrium iron garnet and ferrite materials, which is applied in the field of yttrium iron garnet ferrite materials and its preparation, can solve the problems of limiting the high power performance of ferrite materials, coarse sintered crystal grains, and poor uniformity. Achieve the effect of excellent high power bearing capacity, fine and uniform grain, and excellent grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

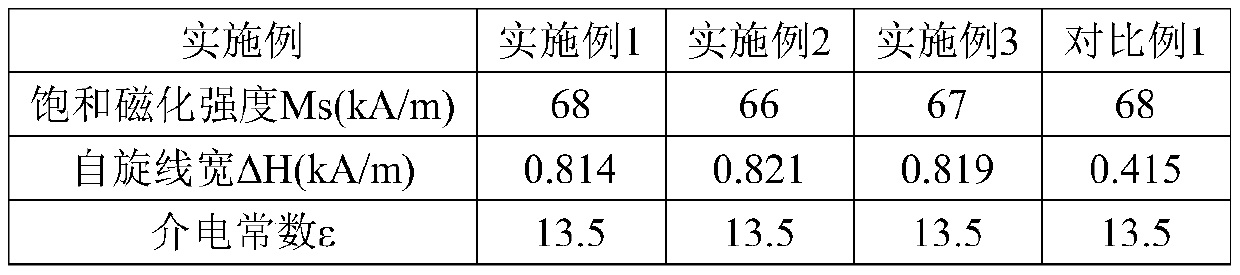

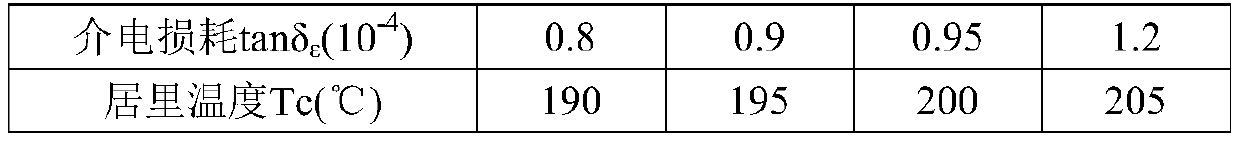

Embodiment 1

[0025] A preparation method of yttrium iron garnet ferrite material, comprising the following steps:

[0026] (1) Mixing: raw materials are weighed in the following parts by weight: Y 2 o 3 45 parts, Gd 2 o 3 1.5 parts, CaO1.5 parts, CuO1.0 parts, Fe 2 o 3 48.5 copies, In 2 o 3 1.5 parts, V 2 o 5 0.3 parts, Al 2 o 3 1.7 servings. Y 2 0 3 , Fe 2 0 3 The average particle size of the raw materials is 2.2 μm; the average particle size of the other raw materials is 0.6 μm; the above raw materials are added to the ball mill for wet ball milling, the mass ratio of raw materials, balls and water is 1:7:1.4, and dried after ball milling , cross 30 mesh sieves.

[0027](2) Pre-burning: the above sieved powder is heated up to 650°C at a heating rate of 8°C / min, then to 1050°C at a heating rate of 100°C / min, and then cooled at a cooling rate of 80°C / min to room temperature;

[0028] (3) Secondary ball milling: Pass the pre-fired powder through a 30-mesh sieve, and then a...

Embodiment 2

[0032] A preparation method of yttrium iron garnet ferrite material, comprising the following steps:

[0033] (1) Mixing: raw materials are weighed in the following parts by weight: Y 2 o 3 42.5 parts, Gd 2 o 3 2.5 parts, CaO1.8 parts, CuO1.5 parts, Fe 2 o 3 49.3 copies, In 2 o 3 1.7 parts, V 2 o 5 0.2 parts, Al 2 o 3 0.5 servings. Y 2 0 3 , Fe 2 0 3 The average particle size of the raw materials is 2.0 μm; the average particle size of the rest of the raw materials is 0.5 μm; the above raw materials are added to the ball mill for wet ball milling, the mass ratio of raw materials, balls and water is 1:6:1.5, and dried after ball milling , Cross 30 mesh sieves.

[0034] (2) Pre-burning: the above sieved powder is heated up to 700°C at a heating rate of 10°C / min, then to 1100°C at a heating rate of 80°C / min, and then cooled at a cooling rate of 100°C / min to room temperature;

[0035] (3) Secondary ball milling: pass the pre-fired powder through a 30-mesh sieve, ...

Embodiment 3

[0039] A preparation method of yttrium iron garnet ferrite material, comprising the following steps:

[0040] (1) Mixing: raw materials are weighed in the following parts by weight: Y 2 o 3 45.5 parts, Gd 2 o 3 0.5 parts, 1.0 parts of CaO, 0.5 parts of CuO, Fe 2 o 3 50.5 parts, In 2 o 3 1.0 parts, V 2 o 5 0.5 parts, Al 2 o 3 0.5 servings. Y 2 0 3 , Fe 2 0 3 The average particle size of the raw materials is 2.1 μm; the average particle size of the remaining raw materials is 0.7 μm; the above raw materials are added to the ball mill for wet ball milling, the mass ratio of raw materials, balls and water is 1:7:1.3, and dried after ball milling , Cross 30 mesh sieves.

[0041] (2) Pre-burning: the above sieved powder is heated up to 650°C at a heating rate of 5°C / min, then to 1050°C at a heating rate of 100°C / min, and then cooled at a cooling rate of 100°C / min to room temperature;

[0042] (3) Secondary ball milling: Pass the pre-burned powder through a 30-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com