Polyaspartic acid coating for heavy corrosion prevention as well as preparation method and application thereof

A polyaspartic acid, heavy-duty anti-corrosion technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of fast handling, environmental protection and green, and achieve the effects of shortening hardening time, low VOC, and improving curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

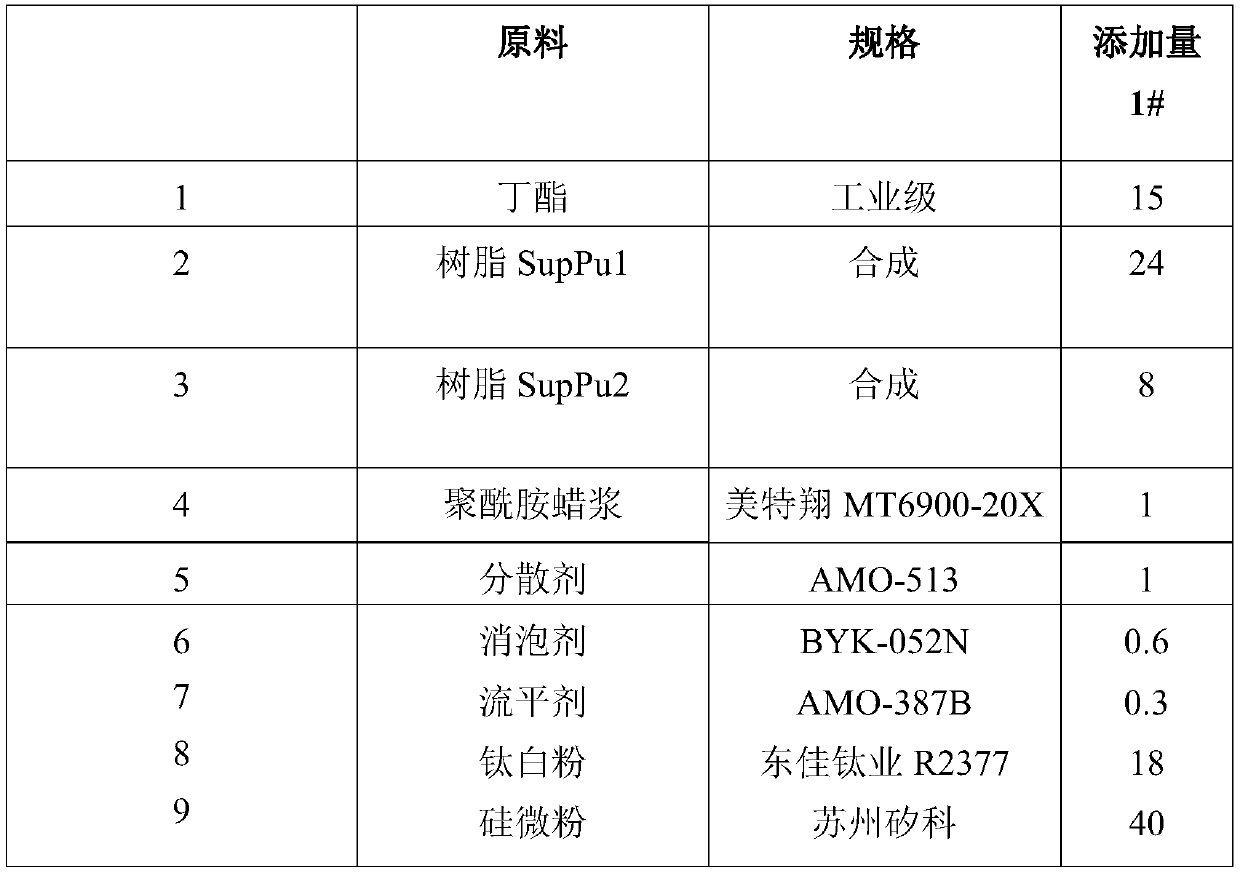

[0021] Component A:

[0022]

[0023] Table 1 Composition of Group A

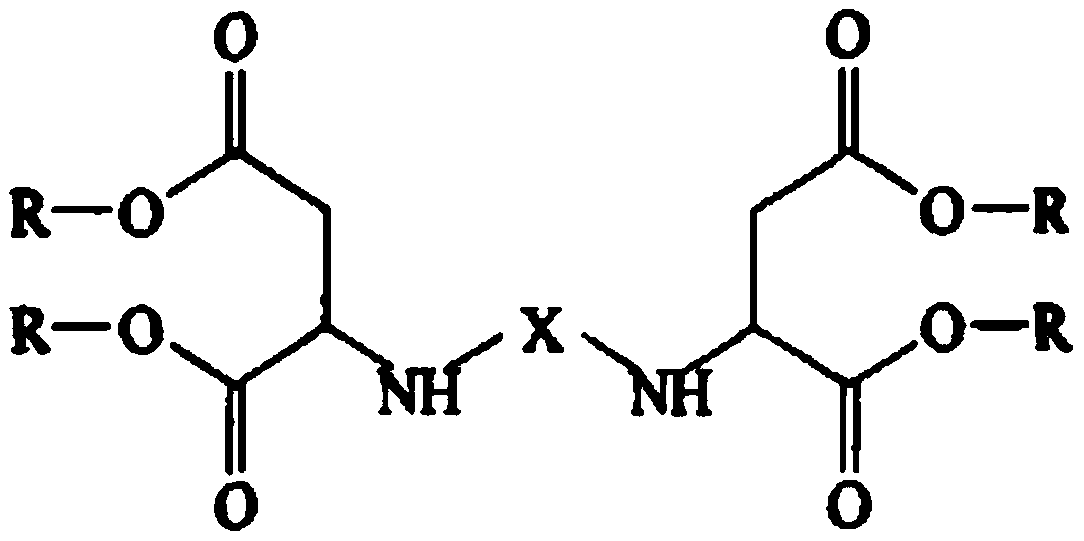

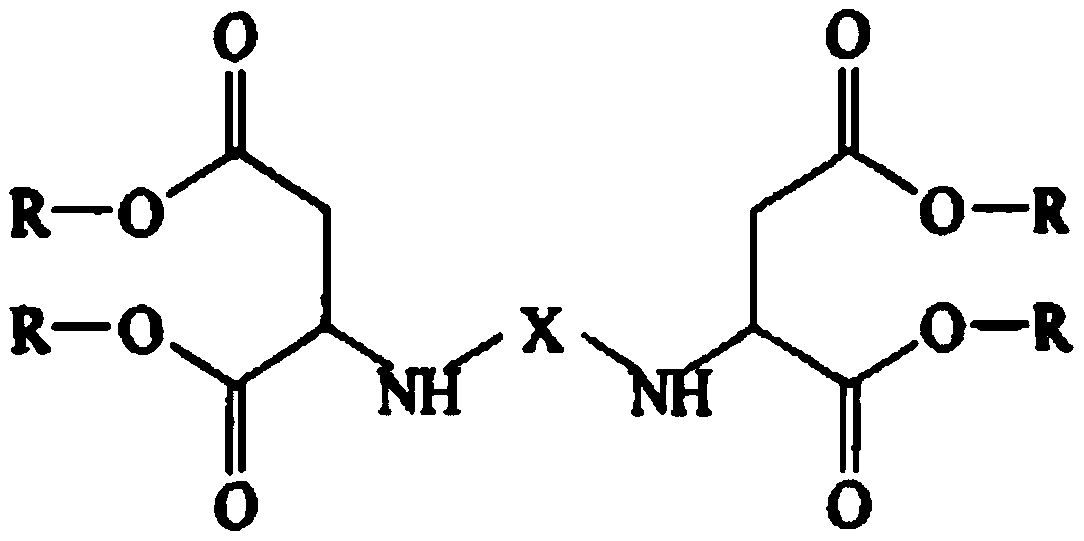

[0024] Preparation process: Put component 1-7, 800 rpm into the tank and stir for 20 minutes, add components 8 and 9, stir for 20 minutes at 800 rpm, and then grind all the materials to a fineness of 30um or less through a grinder (specifically ground, 25-30um), through 200 mesh filter packs to obtain the first component. In resin SupPu1, R is -CH 3 , X is -CH 2 ; In resin SupPu2, R is -CH 2 -CH 3 , X is (CH 2 ) 15 .

[0025] Component B: Bayer N3390

[0026] The ratio of A to B is 5:1 (mass ratio)

[0027] When in use, mix components A and B evenly at a mass ratio of 5:1, then add a small amount of diluent (the diluent is butyl acetate, the mass ratio of component A: component B: diluent 5:1:0.5) and spray That's it. The coating has high solid content and low VOC. The product can form hardness within 20 minutes (the hardness is measured as 3H (Mitsubishi pencil), GB / T 6739), and it can be tr...

Embodiment 2

[0031] Part A

[0032]

[0033]

[0034] Table 3 Composition of Group A

[0035] The preparation process of component A: Put 1-7 components into the tank, stir for 20 minutes at 800 rpm, add components 8 and 9, stir for 20 minutes at 800 rpm, and then grind all the materials through a grinder until fine Degree below 30um (specifically, 25-30um), through 200 mesh filter screens, filter and package to obtain the first component. In resin SupPu1, R is -CH 3 , X is -(CH 2 ) 2 ; In resin SupPu2, R is -CH 2 -CH 3 , X is (CH 2 ) 16 .

[0036] Component B: BASF HI-190

[0037] The ratio of A and B components is 5:1 (mass ratio):

[0038] When in use, mix components A and B evenly at a mass ratio of 5:1, then add a small amount of diluent (the diluent is butyl acetate, the mass ratio of component A: component B: diluent 5:1:0.5) and spray That's it. The coating has high solid content and low VOC. The product can form hardness within 30 minutes (the hardness is measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com