High-frequency glue and high-frequency flexible copper-clad laminate applying high-frequency glue

A flexible copper-clad laminate and high-frequency technology, which is applied in the field of copper-clad laminate preparation, can solve problems such as the inability to obtain processing technology, and achieve the effects of low cost, low dielectric loss, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0028] A high-frequency glue consisting of the following components by mass fraction: 100g of DCPD-modified epoxy resin from Japan DIC 7200H, 200g of DCPD-modified benzo resin from Taiwan Jinlong Chemical, Japan KI Chemical BMI-70 20g of BMI resin, 80g of SMA anhydride curing agent from Greville EF40 in the United States, 40g of low-dielectric phosphazene flame retardant from Fushimi Pharmaceutical PF-300B in Japan, 60g of low-dielectric rubber toughening agent from JSR-906 in Japan, and Sinopec’s Butanone solvent 400g.

[0029] Weigh the raw materials according to the mass fraction of the above formula, put them into a stirring tank, and stir at a temperature of 50°C at a speed of 300rpm for 2 hours; Frequency glue A.

Embodiment B

[0031] A kind of high-frequency glue, is made up of the component of following mass fraction: the trifunctional epoxy resin 150g of Japan Mitsubishi 1031H60, the polyphenylene ether resin (PPO) 150g of American Sabic 9000, the BMI resin 20g of Japan KI chemical industry BMI-70, 80g of SMA anhydride curing agent from Greville EF40 in the United States, 40g of low-dielectric phosphazene flame retardant from Fushimi Pharmaceutical PF-300B in Japan, 60g of low-dielectric rubber toughening agent from Japan JSR-906, and 400g of butanone solvent from Sinopec .

[0032] Weigh the raw materials according to the mass fraction of the above formula, put them into a stirring tank, and stir at a temperature of 50°C at a speed of 300rpm for 2 hours; Frequency glue B.

Embodiment 1

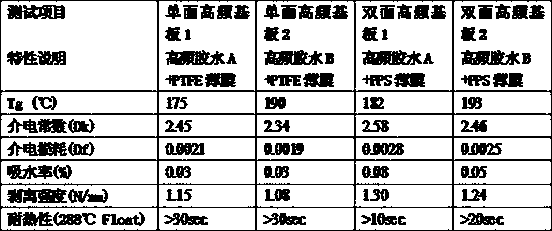

[0034] Take the high-frequency glue A and apply it on the PTFE film, and bake it at 120°C for 30 minutes; then cover the copper foil on the side of the PTFE film coated with the high-frequency glue, and press it at 180°C for one hour; finally, the hot-pressed PTFE The film was cured in an oven at 200° C. for 2 hours to obtain a single-sided high-frequency substrate 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com