Plant-based lubricating oil and preparation method thereof

A lubricating oil, plant-based technology, applied in the field of lubricating oil, can solve the problems of anti-oxidation, poor high temperature resistance, poor high temperature resistance, poor oxidation resistance, etc., and achieve improved high temperature resistance, excellent wear resistance, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

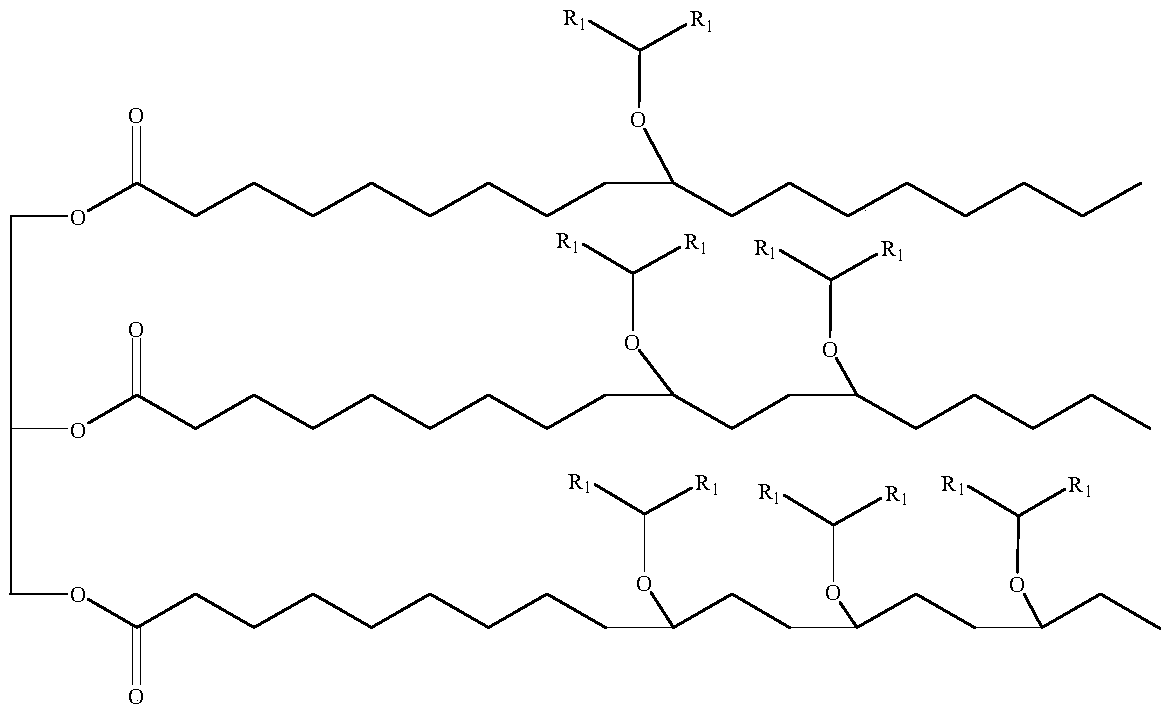

Image

Examples

Embodiment 1

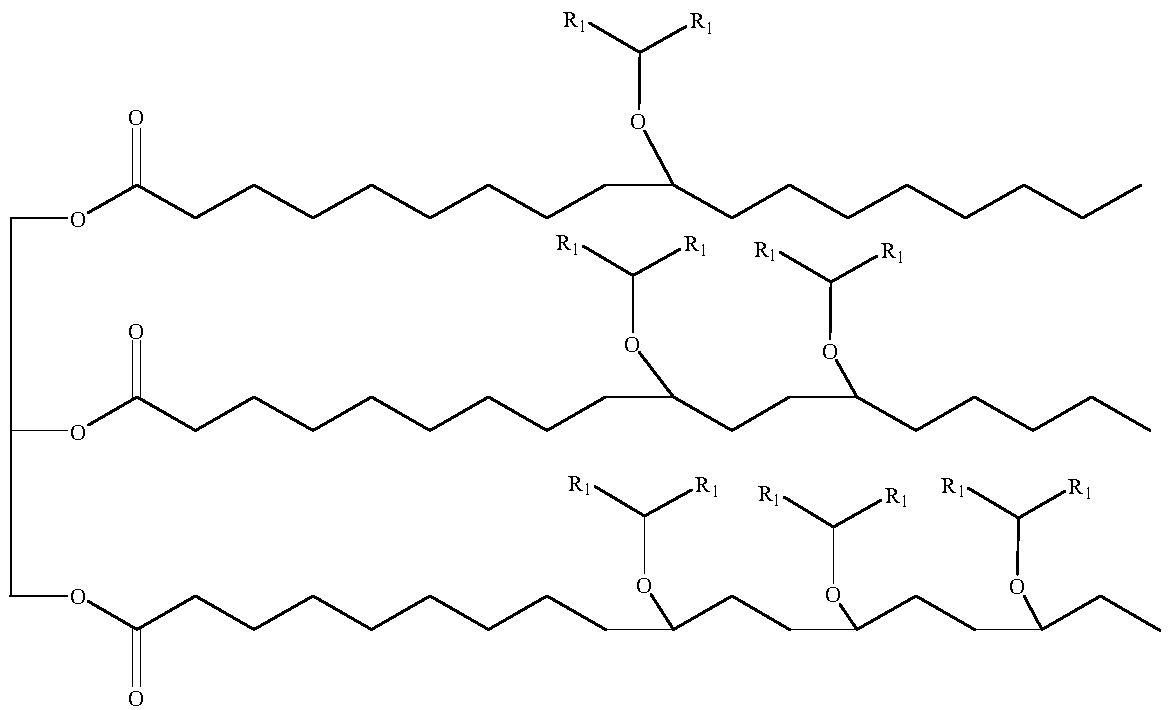

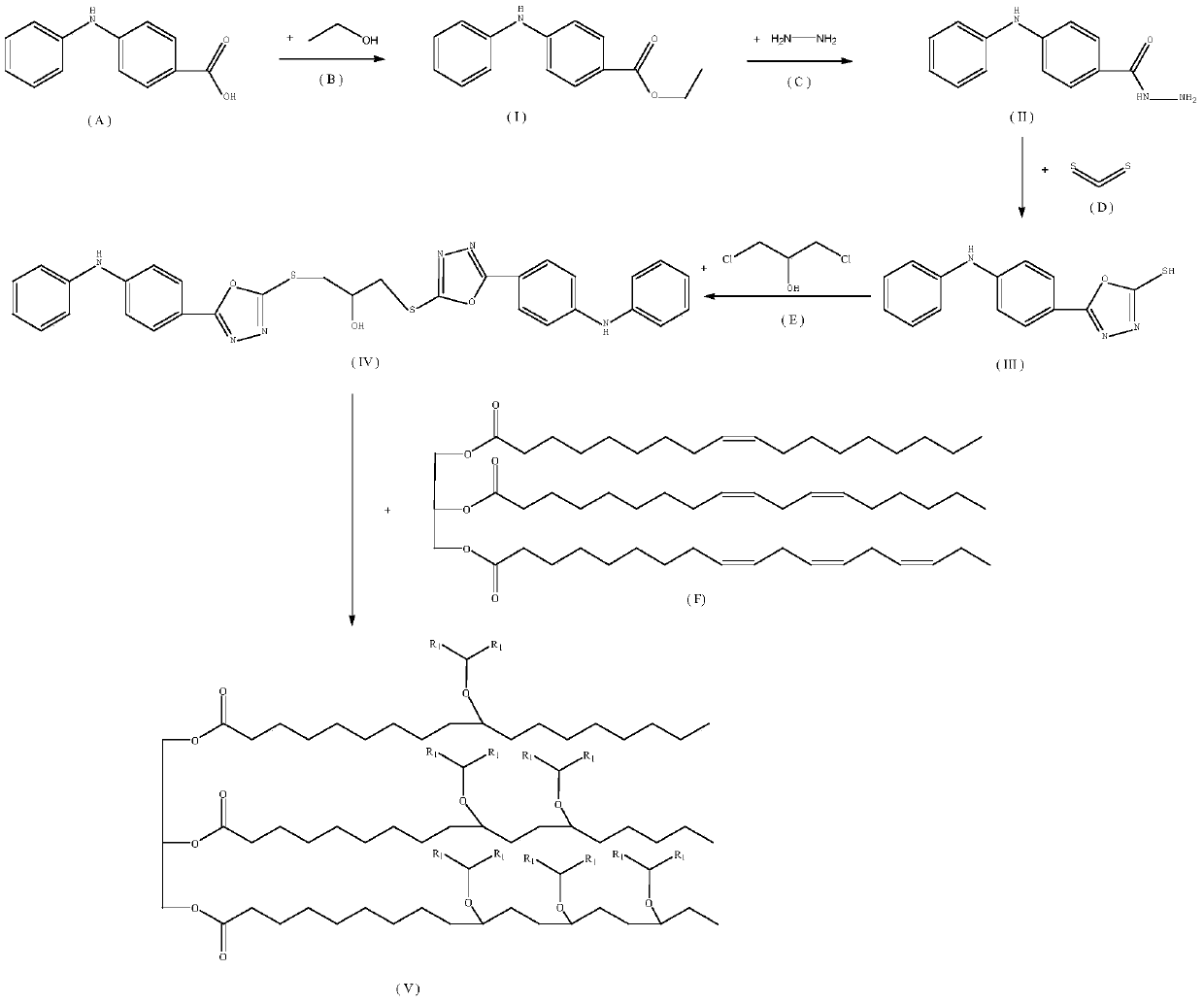

[0043] Step (1) Add 1mol of benzoic acid derivative (A) to 10mol of dehydrated ethanol (B) and stir, add 0.5wt% sulfuric acid, heat and reflux at 120°C for 5h, pour it into ice water after the reaction is over, take the oil layer liquid, Carry out extraction and purification with ether, vacuum dry, obtain intermediate product I (IR: 3500cm -1 : -OH disappears; 3401cm -1 : Secondary-NH exists; 1689cm -1 :-C=O exists).

[0044] Step (2) 1mol I is dissolved in 10mol absolute ethanol, is added in the constant pressure dropping funnel, is added dropwise in the absolute ethanol that is dissolved with 1mol hydrazine (C), heats and refluxes for 18h, after the reaction finishes, the reaction mixes The solution was poured into crushed ice, filtered to obtain a precipitate, washed with water, and recrystallized from ethanol to obtain the intermediate product II (IR: 3402cm -1 : Secondary-NH exists and strengthens; 3483cm -1 : Presence of Bo-NH; 1689cm -1 :-C=O exists).

[0045] Ste...

specific Embodiment 2-6

[0048] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com