AlGaN-based homogeneously integrated optoelectronic chip and preparation method thereof

A technology for optoelectronic chips and quantum wells, which is applied in the manufacturing of circuits, electrical components, and final products, etc., can solve the problems of reducing the working efficiency of devices, serious separation of detection and emission bands, etc. The effect of big data transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

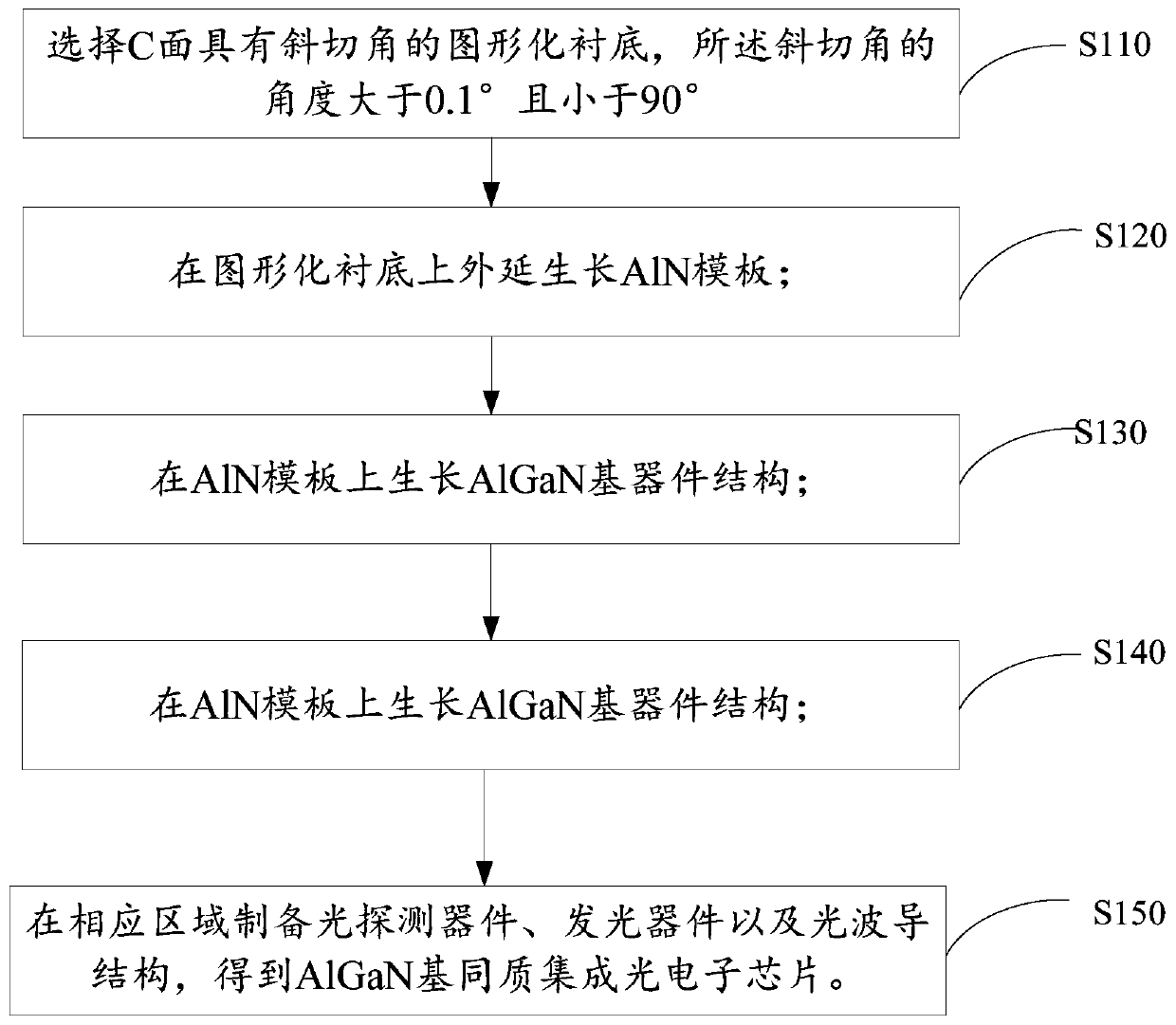

[0033] see figure 1 , the invention provides a method for preparing an AlGaN-based homogeneously integrated optoelectronic chip, comprising:

[0034] S110. Select a patterned substrate with a bevel angle on the C surface, and the angle of the bevel angle is greater than 0.1° and less than 90°;

[0035] Specifically, in one embodiment, the patterned substrate material is sapphire, silicon or silicon carbide.

[0036] S120, epitaxially growing an AlN template on a patterned substrate;

[0037] The means of epitaxial growth of AlN template materials include but not limited to metal-organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE), hydride vapor phase epitaxy (HVPE) and other epitaxial growth technologies; the active area of the optoelectronic chip structure is mainly a quantum well structure;

[0038] S130, growing an AlGaN-based device structure on an AlN template;

[0039] Specifically, in one embodiment, the AlGaN-based device structure includes n-A...

Embodiment 1

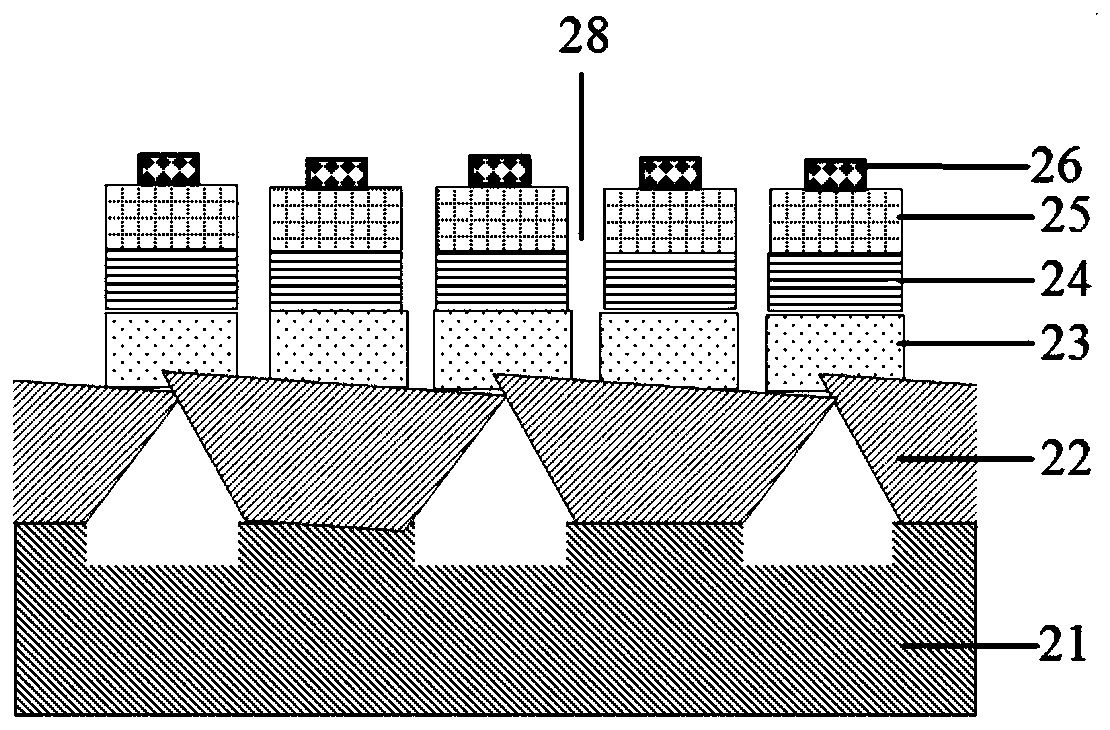

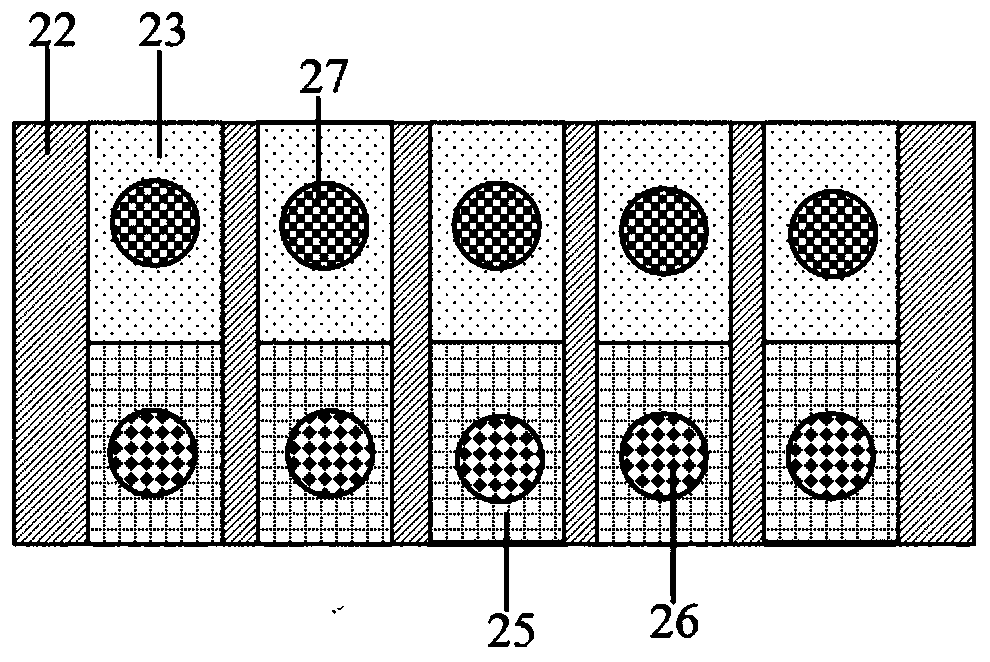

[0051] refer to Figure 2a-2c , three views of the device structure provided in this embodiment, in this embodiment, the preparation method of the AlGaN-based homogeneous integrated optoelectronic chip provided by the present invention includes the following steps:

[0052] Select the desired patterned substrate 21 of the epitaxial AlGaN material, the c-plane (ie (0001) plane) sapphire patterned substrate, and the bevel angle is 0.2° in the direction along the m-plane.

[0053] Using a two-step growth method, AlN material is epitaxially grown as template 22 .

[0054] Epitaxially grow n-AlGaN material 23 on the AlN template to form AlGaN material wing regions and mesa regions. Since the mobility of Ga atoms is greater than that of Al atoms, it is more conducive to moving to the mesa region for nucleation and growth. Therefore, the Al composition of the AlGaN material in the mesa region is relatively low. Low.

[0055] The AlGaN quantum well structure 24 is epitaxially grown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com