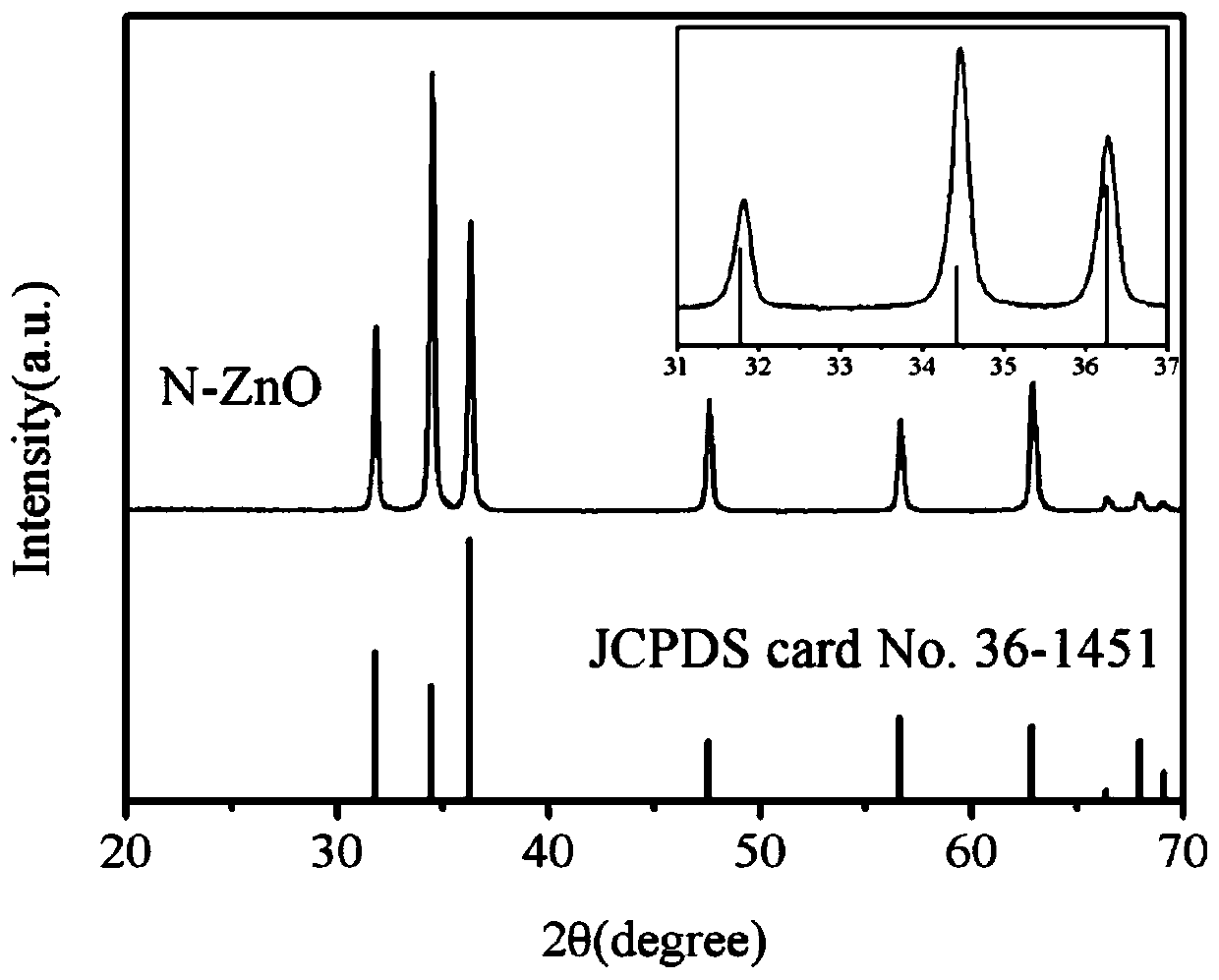

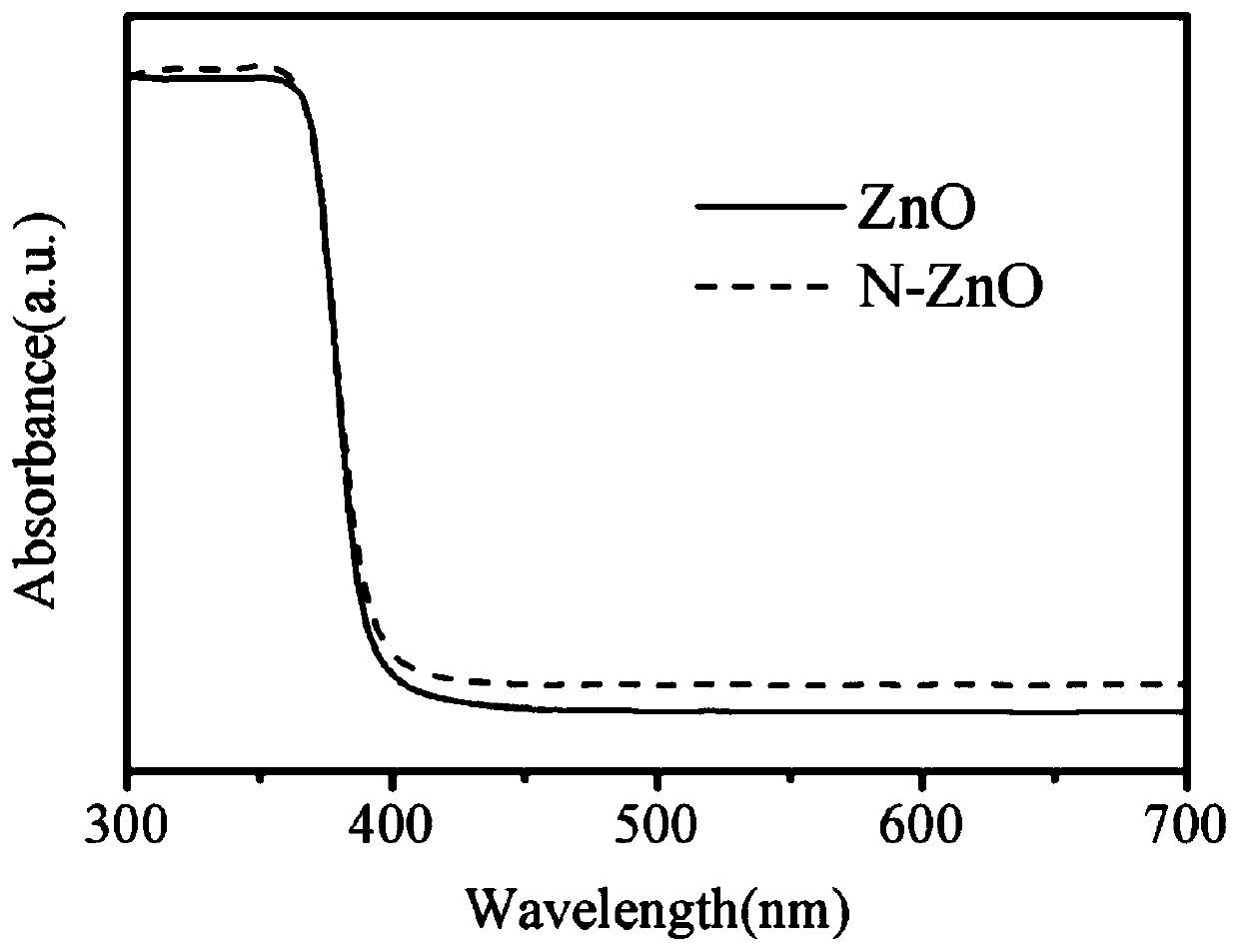

Preparation method of nitrogen-doped modified zinc oxide visible-light photocatalyst

A zinc oxide and nitrogen doping technology, which is applied in the preparation and application of nanomaterials, can solve the problems of ineffective separation of photogenerated carriers and holes, limitations on the industrialization of pure ZnO semiconductor materials, and low utilization of light absorption. , to achieve the effects of broadening the absorption range, environmentally friendly process methods, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A preparation method of nitrogen-doped modified zinc oxide visible light catalyst, comprising the following steps:

[0019] (1), weigh 2.6774g zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) solid, Zn(CH 3 COO) 2 2H 2 O was added to 30mL deionized water, stirred at room temperature for 30min at a speed of 500rpm, and dissolved completely to form solution A;

[0020] (2) Weigh 1.2617g of hexamethylenetetramine (abbreviation: HMTA) solid, add HMTA into solution A, stir at room temperature for 1 hour, and rotate at 500rpm, so that it dissolves to form solution B;

[0021] (3) After that, transfer the solution B to the autoclave, then put the autoclave into an oven at 95°C for 6 hours, cool it down to room temperature naturally, and perform centrifugation at 6000rpm for 6min, then discard The supernatant and sediment were washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com