Tubular porous titanium film-ozone contact reaction device and water treatment method thereof

A technology of ozone contact and reaction device, which is used in oxidation water/sewage treatment, water/sewage treatment, special compound water treatment, etc., to achieve the effect of efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

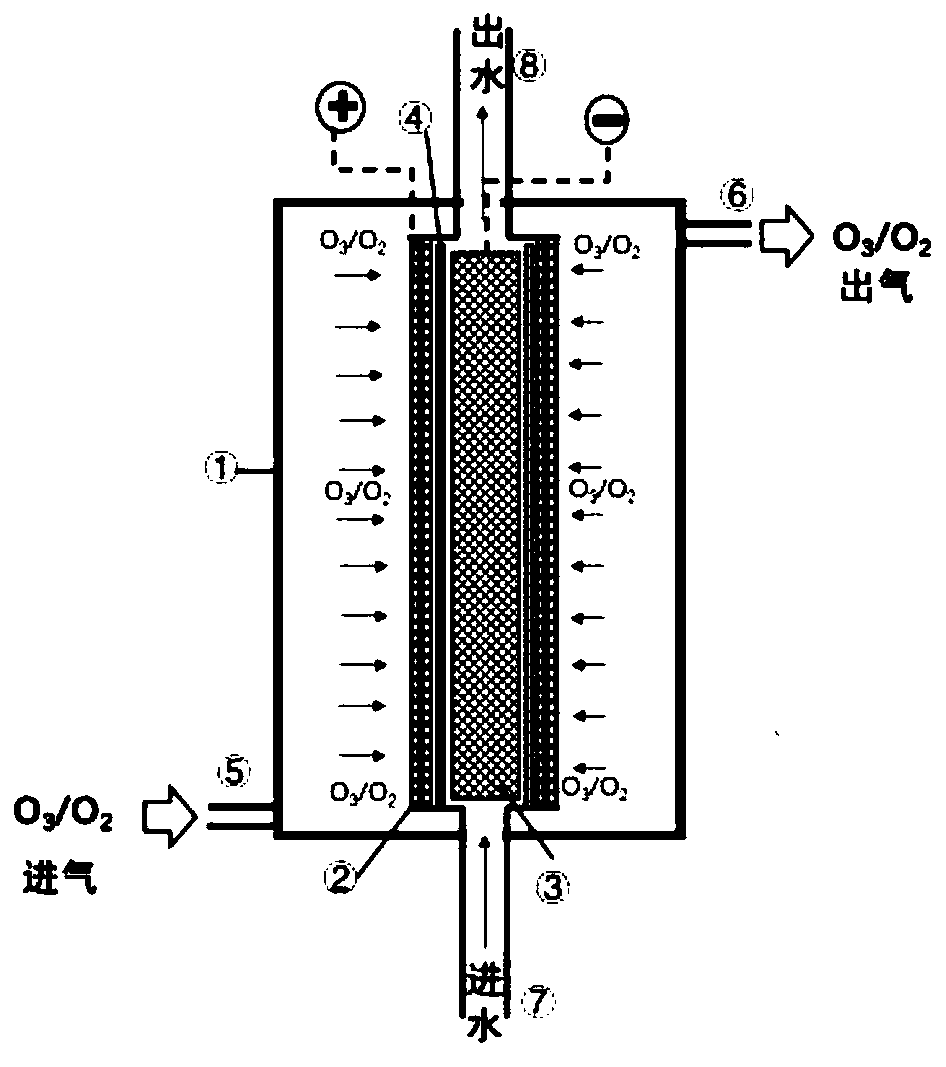

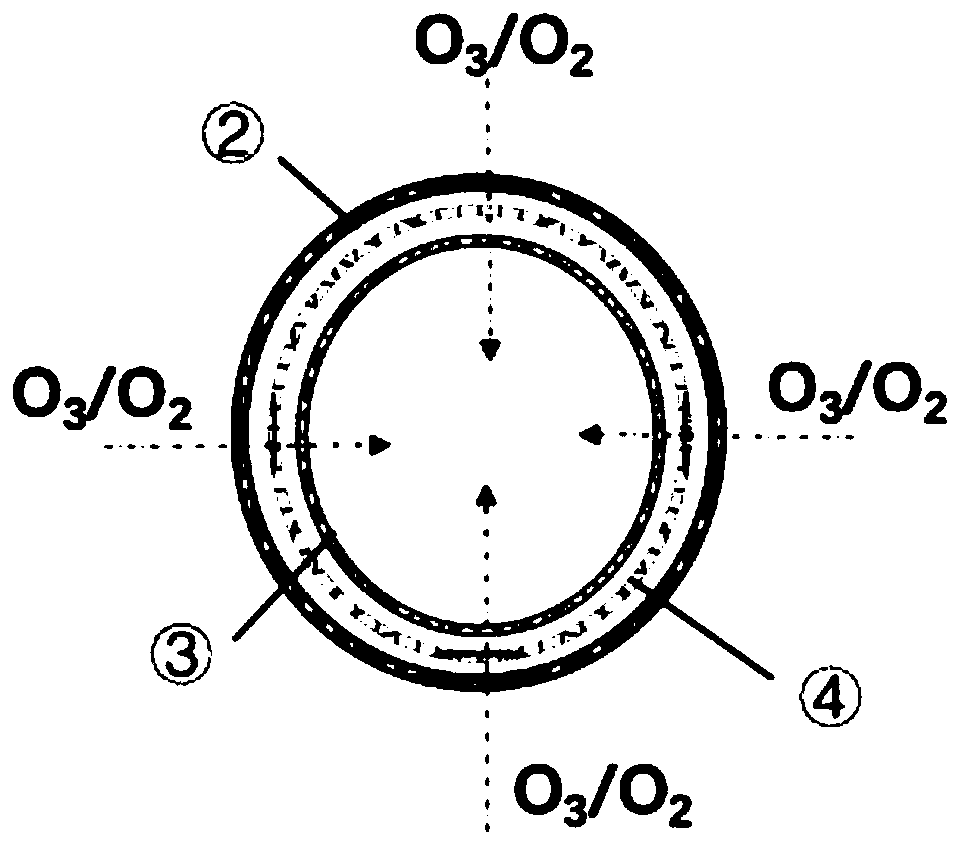

[0034] figure 1 It is a structural schematic diagram of a tubular porous titanium membrane-ozone contact reaction device, figure 2 For the top view of the electrode, refer to figure 1 with figure 2 , the device includes: a cavity ①, a tubular porous titanium membrane electrode ② and a counter electrode ③. The tubular porous titanium membrane electrode ② is arranged in the center of the cavity ①, and the counter electrode ③ is arranged inside the tubular porous titanium membrane electrode ②, and a nylon mesh ④ is used as a separation material between the two to prevent short circuit. The bottom and top of the cavity ① are respectively provided with an air inlet ⑤ and an air outlet ⑥. The lower end and the upper end of the tubular porous titanium membrane electrode ② are water inlet ⑦ and water outlet ⑧ respectively. Tubular porous titanium film electrode ② is used as the working electrode, including a tubular porous titanium substrate and TiO2 loaded on the substrate 2 N...

Embodiment 2

[0039] figure 1 It is a structural schematic diagram of a tubular porous titanium membrane-ozone contact reaction device, figure 2 For the top view of the electrode, refer to figure 1 with figure 2 , the device includes: a cavity ①, a tubular porous titanium membrane electrode ② and a counter electrode ③. The tubular porous titanium membrane electrode ② is arranged in the center of the cavity ①, and the counter electrode ③ is arranged inside the tubular porous titanium membrane electrode ②, and a nylon mesh ④ is used as a separation material between the two to prevent short circuit. The bottom and top of the cavity ① are respectively provided with an air inlet ⑤ and an air outlet ⑥. The lower end and the upper end of the tubular porous titanium membrane electrode ② are water inlet ⑦ and water outlet ⑧ respectively. The tubular porous titanium membrane electrode ② is used as the working electrode, which consists of a tubular porous titanium substrate and a graphene cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com