High-strength and high-toughness hyperbranched polymer hydrogel and preparation method thereof

A hyperbranched polymer, high-strength and high-toughness technology, used in the field of biomedical materials to achieve the effects of good toughness, improved mechanical properties, and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] N-acryloyl glycinamide (NAGA) is dissolved in dimethyl sulfoxide according to the solid content of 10%, and then the initiator benzophenone (BP) is added to the above solution, and the consumption of the initiator is N-propylene 0.0% of the mass of acylglycinamide (NAGA), use inert gas (such as nitrogen, argon or helium) to remove oxygen in the reaction system, the mold is irradiated in a UV curing box for 60 minutes to ensure sufficient initiation of free radical polymerization, followed by Open the mold and take out the gel, soak it in deionized water for 36 hours to reach a swelling equilibrium, and replace the deionized water every 12 hours to obtain a high-strength and high-tough hyperbranched polymer hydrogel (HB-PNAGA).

Embodiment 2

[0024] N-acryloyl glycinamide (NAGA) is dissolved in tetrahydrofuran according to the solid content of 40%, and then the initiator benzophenone (BP) is added to the above solution, and the consumption of the initiator is N-acryloyl glycinamide. (NAGA) 3% of the mass, use inert gas (such as nitrogen, argon or helium) to remove oxygen in the reaction system, the mold is irradiated in a UV curing box for 20 minutes to ensure sufficient initiation of free radical polymerization, and then open the mold to take out the condensation The gel was soaked in deionized water for 72 hours to reach a swelling equilibrium, and the deionized water was replaced every 12 hours to obtain a high-strength and high-tough hyperbranched polymer hydrogel (HB-PNAGA).

Embodiment 3

[0026] N-acryloyl glycinamide (NAGA) was dissolved in N,N-dimethylformamide according to the solid content of 20%, and then the initiator benzophenone (BP) was added to the above solution, and the amount of the initiator was It is 1% of the mass of N-acryloyl glycinamide (NAGA), using inert gas (such as nitrogen, argon or helium) to remove oxygen in the reaction system, and the mold is irradiated in a UV curing box for 40 minutes to ensure sufficient initiation freedom Then, the mold was opened to take out the gel, soaked in deionized water for 48 hours to reach the swelling equilibrium, and the deionized water was replaced every 12 hours to obtain a high-strength and high-tough hyperbranched polymer hydrogel (HB-PNAGA).

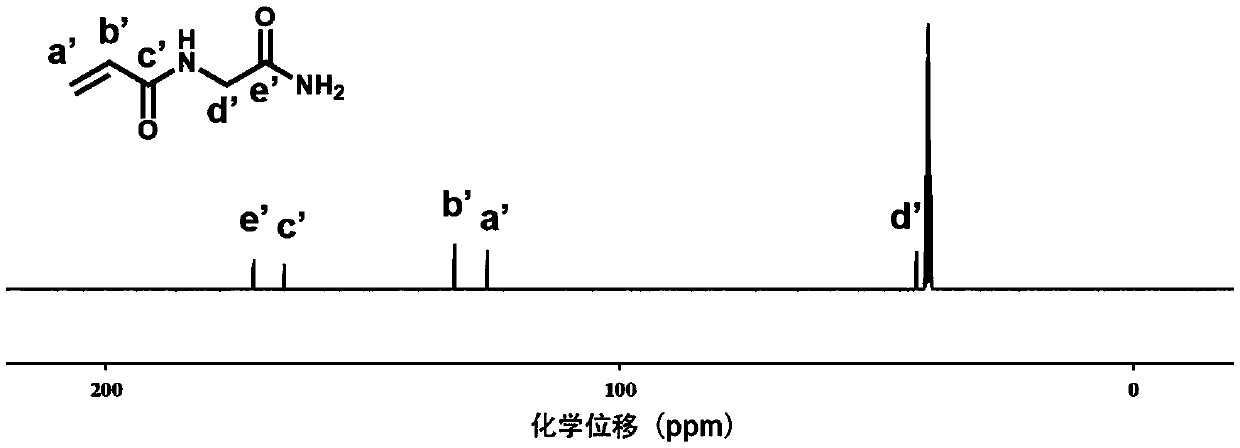

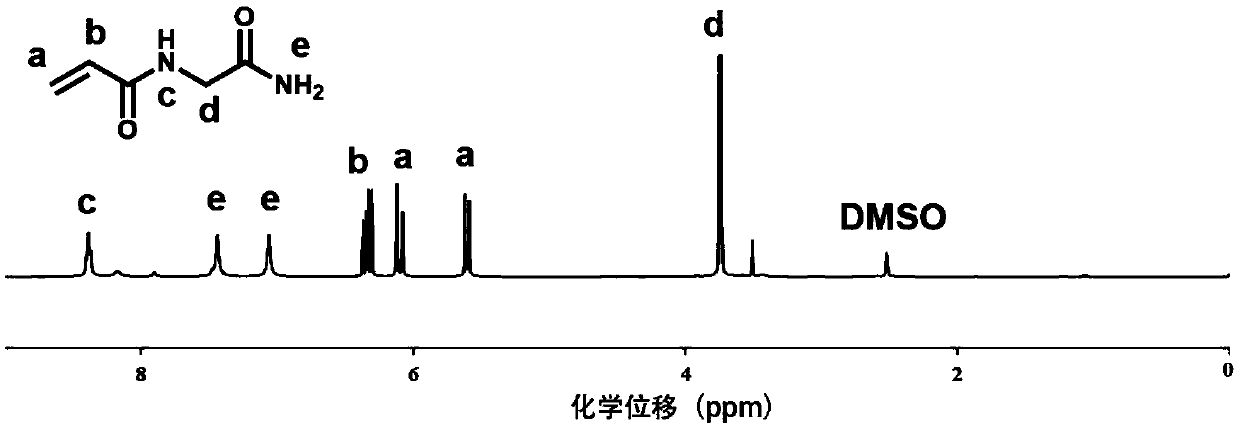

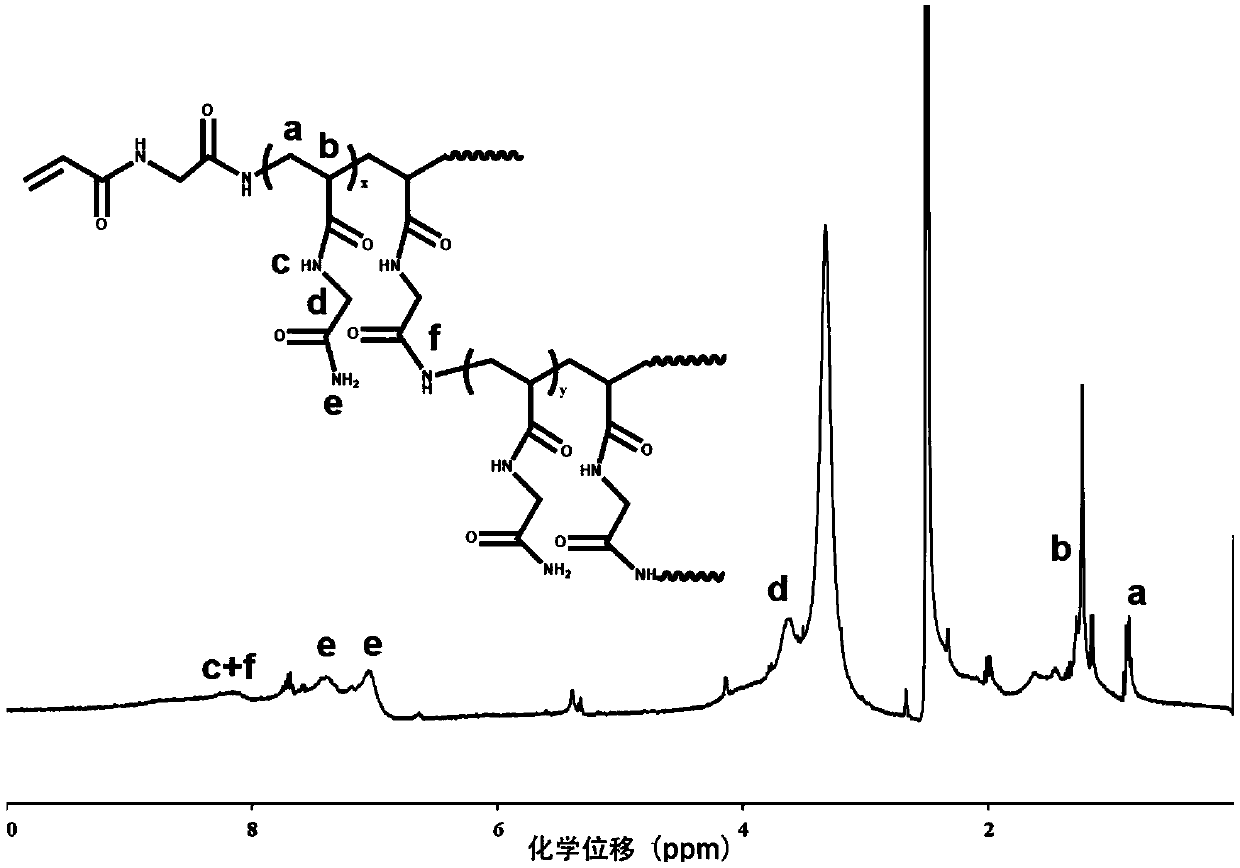

[0027] from image 3 It can be seen that the characteristic hydrogen peaks of a, b, c, d, e, and f all exist, and the characteristic peaks (c+f) in the high-strength and high-tough hyperbranched polymer hydrogel (HB-PNAGA): e=1 :1, description-NH 2 Scale r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com