Antifouling coating as well as preparation method and application thereof

A technology of antifouling coatings and tapioca starch, which is applied in the field of coatings, can solve the problems of no application, no technical guidance and technical effects, unfavorable starch stability, etc., and achieve the effects of excellent performance, good thixotropy, and excellent covering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a preparation method for the antifouling coating described in the above technical solution, comprising the following steps:

[0065] The solvent and the acrylic resin are first mixed to obtain a resin solution;

[0066] The obtained resin solution is mixed with the remaining raw materials for the second time to obtain the antifouling paint.

[0067] In the present invention, the solvent and the acrylic resin are first mixed to obtain a resin solution. In the present invention, the first mixing is preferably performed under stirring conditions; the stirring speed is preferably 250-350 rpm, more preferably 275-325 rpm, and still more preferably 290-310 rpm. In the present invention, the equipment for performing the first mixing is preferably a multi-purpose disc dispersing machine.

[0068] After obtaining the resin solution, the present invention performs second mixing with the obtained resin solution and other raw materials to obtai...

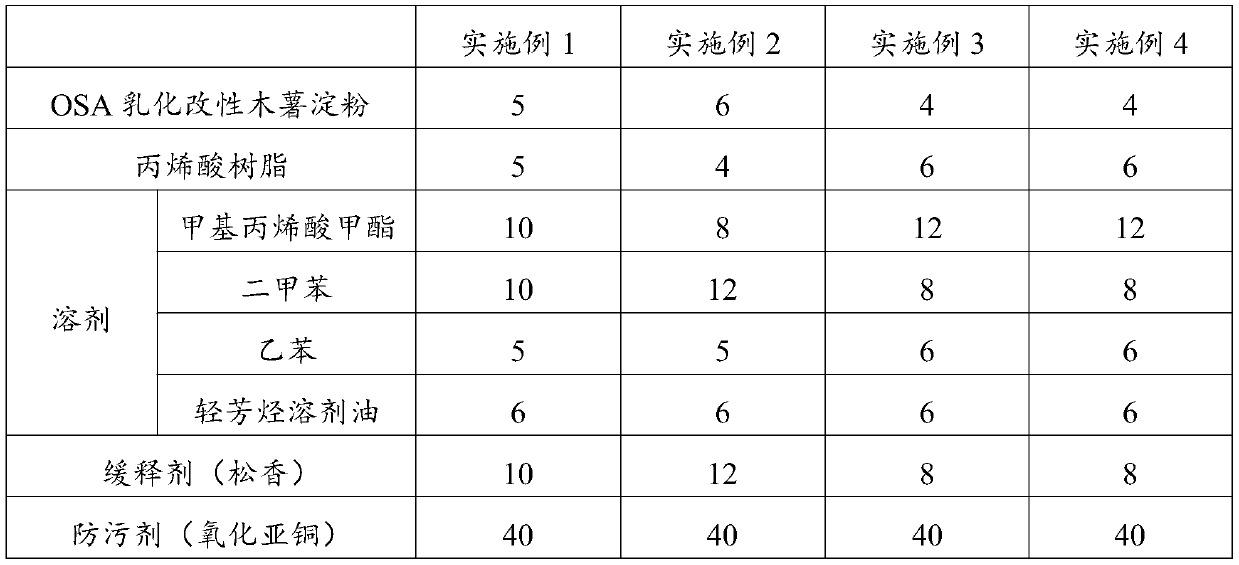

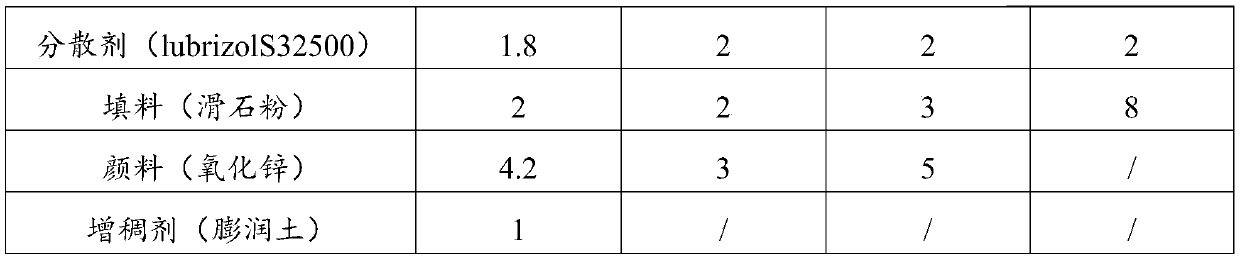

Embodiment 1~4

[0072] The reagents used in Examples 1-4 are all commercially available.

[0073] OSA emulsified modified cassava starch preparation process is:

[0074] Prepare an OSA absolute ethanol solution with a mass fraction of 3%; dry the tapioca starch in an oven at 60°C for 2 hours and take it out, prepare a tapioca starch dispersion with a mass dispersion of 30% with distilled water, and place it in a water bath at 30°C under magnetic stirring Slowly add the dehydrated ethanol solution of OSA into the tapioca starch dispersion under the conditions (the mass ratio of the dehydrated ethanol solution of OSA to the tapioca starch dispersion is 1:1, that is, the mass ratio of OSA to tapioca starch is 1:10); Use a 5% NaOH solution to adjust the pH value of the system to 9; after reacting for 2 hours, use a 4% HCl solution to adjust the pH to neutral, and finally filter the mixed system, wash and filter the solid with absolute ethanol The material was dried several times at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com