Spinning method of regenerated polyester full-dull FDY filaments

A technology of recycled polyester and full extinction, which is applied in the melting of filament raw materials, stretching spinning, and rayon manufacturing. Uniformity, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

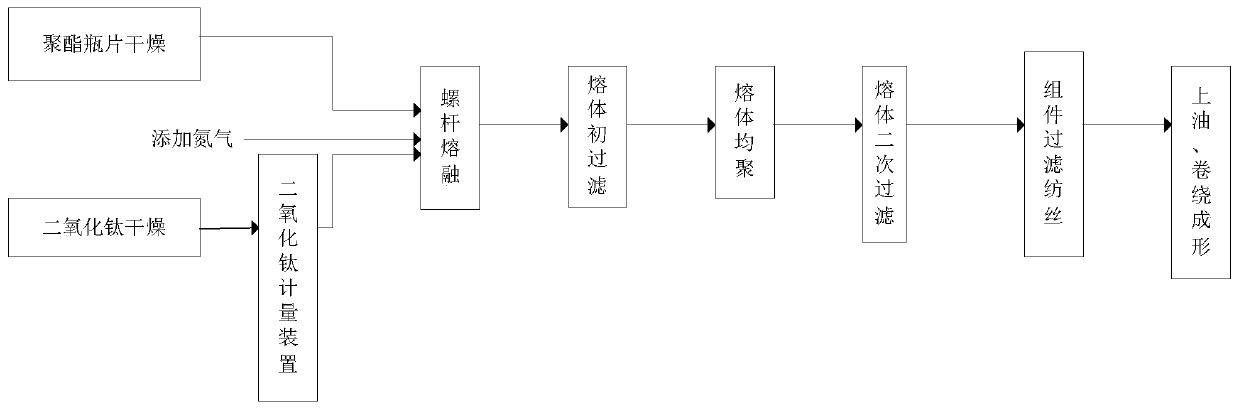

Image

Examples

Embodiment 1

[0038] The recycled polyester bottle flakes are sent to a boiling continuous dryer for drying, with a crystallization temperature of 175°C, a drying temperature of 170°C, and a drying gas flow rate of 350m 3 / h, drying time 6h, bottle flake moisture content 35ppm; drying temperature of matt titanium dioxide masterbatch is 135℃, drying air flow rate is 80m 3 / h, the addition amount of the matting agent masterbatch is 4.5% (the content of titanium dioxide in the matting agent masterbatch is 50%); connect the dried regenerated polyester bottle flakes to the screw port, and add a masterbatch outside the screw feed port Port and a nitrogen addition port. The matting agent masterbatch and the regenerated bottle flakes are connected to the screw feed port synchronously. The nitrogen protective layer separates the air and the material before entering the screw; the temperature of the first to eighth areas of the screw are respectively It is 283℃, 288℃, 292℃, 298℃, 298℃, 295℃, 295℃, 295℃ ...

Embodiment 2

[0044] The recycled polyester bottle flakes are sent to a boiling type continuous dryer for drying. The crystallization temperature is 172°C, the drying temperature is 168°C, and the drying gas flow rate is 350m. 3 / h, drying time 6h, bottle flake moisture content 40ppm; drying temperature of matt titanium dioxide masterbatch is 133℃, drying air flow rate is 80m 3 / h, the addition amount of the matting agent masterbatch is 4.2% (the content of titanium dioxide in the matting agent masterbatch is 50%); connect the dried recycled polyester bottle flakes to the screw port, and add a masterbatch outside the screw feed port Port and a nitrogen addition port. The matting agent masterbatch and the regenerated bottle flakes are connected to the screw feed port synchronously. The nitrogen protective layer separates the air and the material before entering the screw; the temperature of the first to eighth areas of the screw are respectively 280℃, 285℃, 290℃, 295℃, 295℃, 295℃, 292℃, 292℃, t...

Embodiment 3

[0050] The regenerated polyester bottle flakes are sent to a boiling continuous dryer for drying. The crystallization temperature is 168℃, the drying temperature is 163℃, and the drying gas flow rate is 350m. 3 / h, drying time 6h, bottle flake moisture content 50ppm; matting masterbatch drying temperature is 128℃, drying air flow rate is 80m 3 / h, the addition amount of the matting agent masterbatch is 4.0% (the content of titanium dioxide in the matting agent masterbatch is 50%); connect the dried recycled polyester bottle flakes to the screw port, and add a masterbatch outside the screw feed port Port and a nitrogen addition port. The matting agent masterbatch and the regenerated bottle flakes are connected to the screw feed port synchronously. The nitrogen protective layer separates the air and the material before entering the screw; the temperature of the first to eighth areas of the screw are respectively 275℃, 280℃, 285℃, 290℃, 292℃, 292℃, 288℃, 288℃ to obtain recycled poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com