A kind of flexible, transparent conductive film and preparation method thereof

A technology of conductive film and conductive polymer, applied in conductive layer on insulating carrier, equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, etc., can solve the problem of reducing film conductivity, affecting conductivity and permeability. Optical properties, large leakage current of devices, etc., to relieve external stress, improve transmittance, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

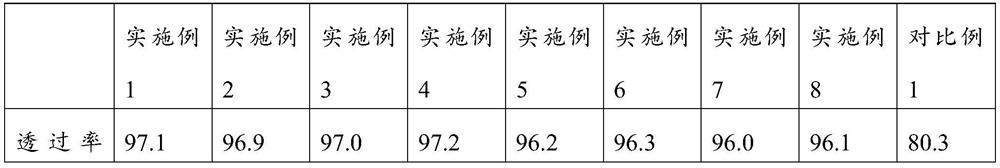

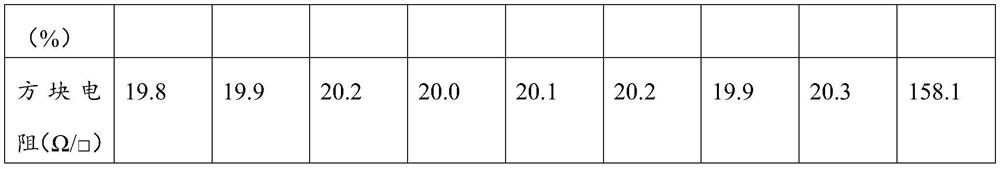

Examples

Embodiment 1

[0062] A method for preparing a flexible, transparent conductive film, comprising the following steps:

[0063] (1) Depositing photonic crystals on the substrate surface, the specific process is: disperse silica nanospheres (with a size of 140-150nm) with ethanol to obtain a dispersion of silica nanospheres with a concentration of 0.1g / L, and then The ethylene terephthalate flexible substrate is immersed in the dispersion liquid, and then ethanol is evaporated at 100°C to form a layer of silicon dioxide nanospheres on the surface of the flexible substrate (that is, to form a photonic crystal film);

[0064] (2) silver nitrate, citric acid, cetyltrimethylammonium bromide and ethanol are mixed to obtain a mixed solution, the concentration of silver nitrate in the mixed solution is 1g / L, and the concentration of citric acid is 0.1g / L , the concentration of cetyltrimethylammonium bromide is 2g / L, then at 100 ℃, under the environment of vacuum degree of 10Pa, the mixed solution is ...

Embodiment 2

[0068] A method for preparing a flexible, transparent conductive film, comprising the following steps:

[0069] (1) Depositing photonic crystals on the surface of the substrate, the specific process is: disperse silica nanospheres (with a size of 130-135nm) with ethanol to obtain a dispersion of silica nanospheres with a concentration of 2g / L, and then polymerize The ethylene naphthalate flexible substrate is immersed in the dispersion liquid, and then ethanol is evaporated at 25° C. to form a layer of silicon dioxide nanospheres on the surface of the flexible substrate (that is, to form a photonic crystal film);

[0070] (2) silver nitrate, citric acid, cetyltrimethylammonium bromide and ethanol are mixed to obtain a mixed solution, the concentration of silver nitrate in the mixed solution is 5g / L, and the concentration of citric acid is 5g / L, The concentration of cetyltrimethylammonium bromide is 0.1g / L, then at 25 DEG C, under the environment of vacuum degree of 100Pa, mixe...

Embodiment 3

[0074] A method for preparing a flexible, transparent conductive film, comprising the following steps:

[0075] (1) Depositing photonic crystals on the substrate surface, the specific process is: disperse silica nanospheres (size is 140-150nm) with ethanol to obtain a dispersion of silica nanospheres, the concentration is 0.5g / L, and then The polyethersulfone resin flexible substrate is immersed in the dispersion liquid, and then evaporates ethanol at 60°C to form a layer of silicon dioxide nanospheres on the surface of the flexible substrate (that is, to form a photonic crystal film);

[0076] (2) silver nitrate, citric acid, cetyltrimethylammonium bromide and ethanol are mixed to obtain a mixed solution, the concentration of silver nitrate in the mixed solution is 2g / L, and the concentration of citric acid is 2g / L, The concentration of cetyltrimethylammonium bromide is 0.1g / L, then at 60 DEG C, under the environment of vacuum degree of 1Pa, the mixed solution is coated on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com