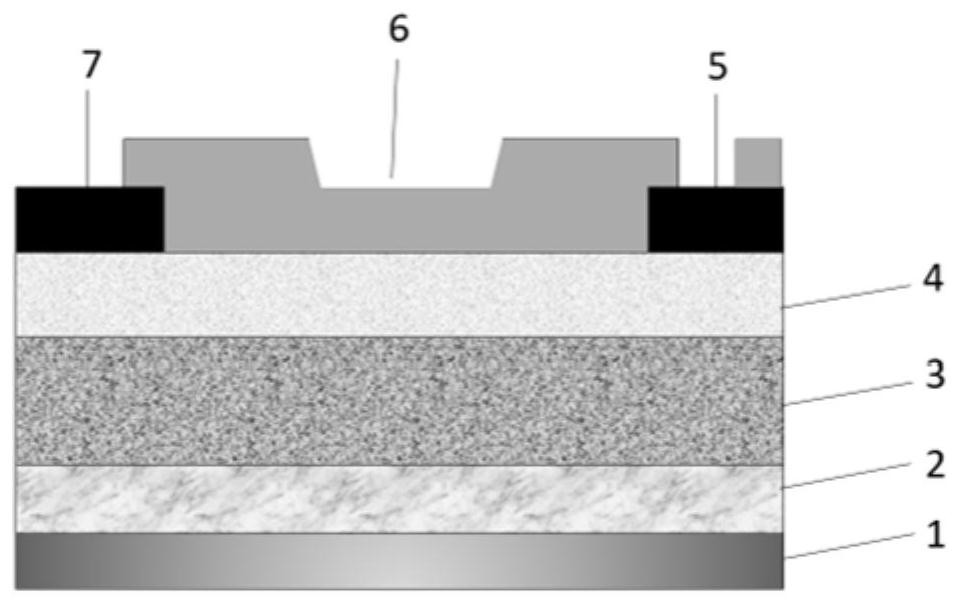

A kind of gan rectifier based on cu substrate and preparation method thereof

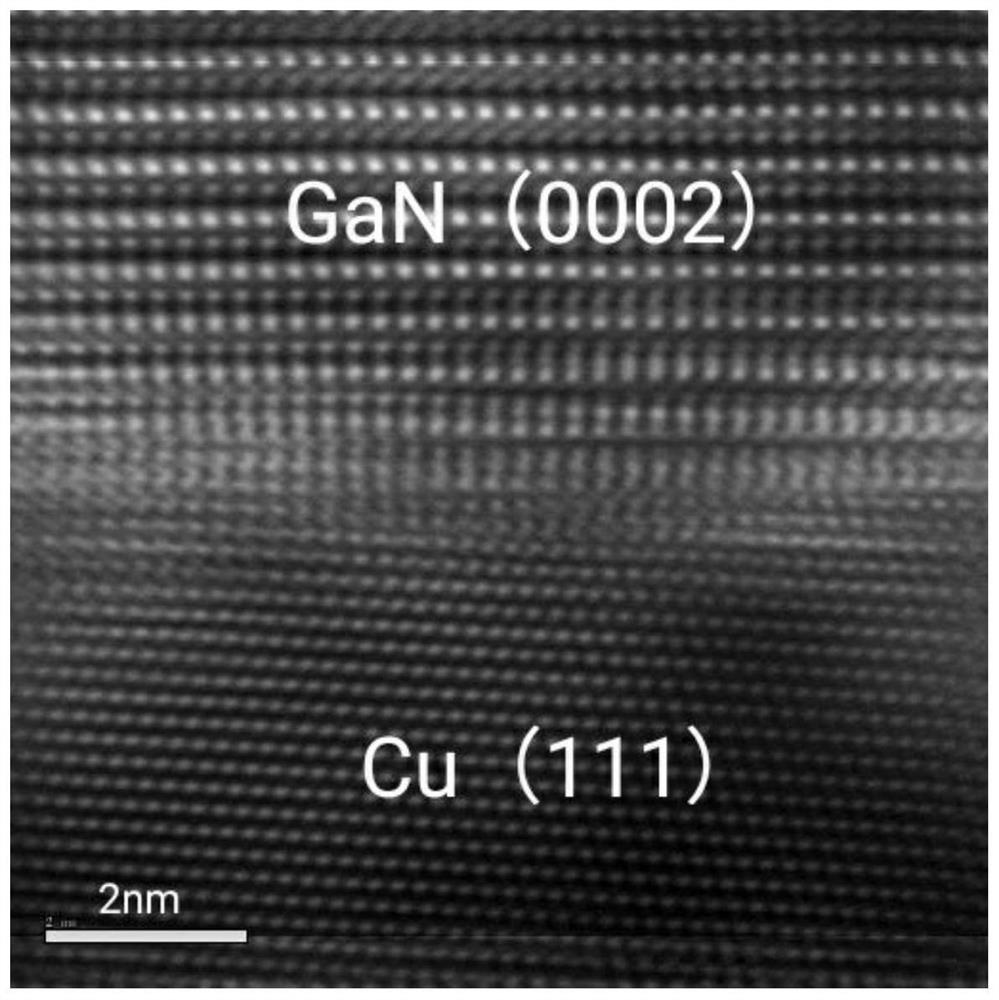

A rectifier and substrate technology, applied in the field of Cu-substrate-based GaN rectifier and its preparation, achieves the effects of stable performance, clear hetero interface and excellent crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a GaN rectifier based on a Cu substrate, comprising the steps of:

[0030] S1 At room temperature, the single crystal Cu(111) substrate was cleaned and dried, then placed in a rapid annealing furnace, fed with 30 sccm argon, and annealed at 400°C to obtain a clean single crystal Cu substrate, and sent to In a pulsed laser deposition (PLD) chamber;

[0031] S2 uses the general process method of electron beam evaporation to selectively deposit a 5 μm graphite layer on a 2-inch GaN target. The target area covered by the graphite layer and the target area not covered by the graphite layer are distributed axisymmetrically, and the area ratio is 2. .

[0032] S3 uses the method of pulsed laser deposition (PLD), setting the energy of the PLD laser to 380mJ, the frequency at 20Hz, the growth temperature at 600°C, the distance between the target and the substrate at 4mm, and the cavity pressure at 4mTorr. 111) A 2μm carbon-doped GaN high-resistance layer...

Embodiment 2

[0038] A method for preparing a GaN rectifier based on a Cu substrate, comprising the steps of:

[0039] S1 At room temperature, the single crystal Cu(111) substrate was cleaned and dried, then placed in a rapid annealing furnace, fed with 30 sccm argon, and annealed at 400°C to obtain a clean single crystal Cu substrate, and sent to In a pulsed laser deposition (PLD) chamber;

[0040] S2 uses the general process method of electron beam evaporation to selectively deposit a 6 μm graphite layer on a 2-inch GaN target. The target area covered by the graphite layer and the target area not covered by the graphite layer are distributed axisymmetrically, and the area ratio is 2. .

[0041] S3 Through the general process method of pulsed laser deposition (PLD), set the energy of the PLD laser to 400mJ, maintain the frequency at 25Hz, maintain the growth temperature at 640°C, maintain the distance between the target and the substrate at 4.5mm, and maintain the cavity pressure at 4.5mT...

Embodiment 3

[0047] A method for preparing a GaN rectifier based on a Cu substrate, comprising the steps of:

[0048] S1 At room temperature, the single crystal Cu(111) substrate was cleaned and dried, then placed in a rapid annealing furnace, fed with 30 sccm argon, and annealed at 400°C to obtain a clean single crystal Cu substrate, and sent to In a pulsed laser deposition (PLD) chamber;

[0049] S2 uses the general process method of electron beam evaporation to selectively deposit a 4.5 μm graphite layer on a 2-inch GaN target. The target area covered by the graphite layer and the target area not covered by the graphite layer are distributed axisymmetrically, and the area ratio is 2.

[0050] S3 Through the general process method of pulsed laser deposition (PLD), set the PLD laser energy to 350mJ, maintain the frequency at 30Hz, maintain the growth temperature at 680°C, maintain the distance between the target and the substrate at 5mm, and maintain the cavity pressure at 5mTorr. A 2μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com