Moxa wool mattress

A moxa velvet and mattress technology, applied in the field of moxa velvet mattresses, can solve problems such as insufficient health care functions, and achieve good antibacterial function, air purification, and good ventilation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

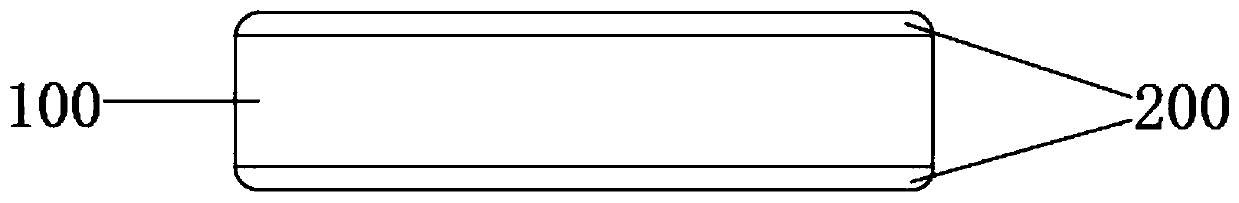

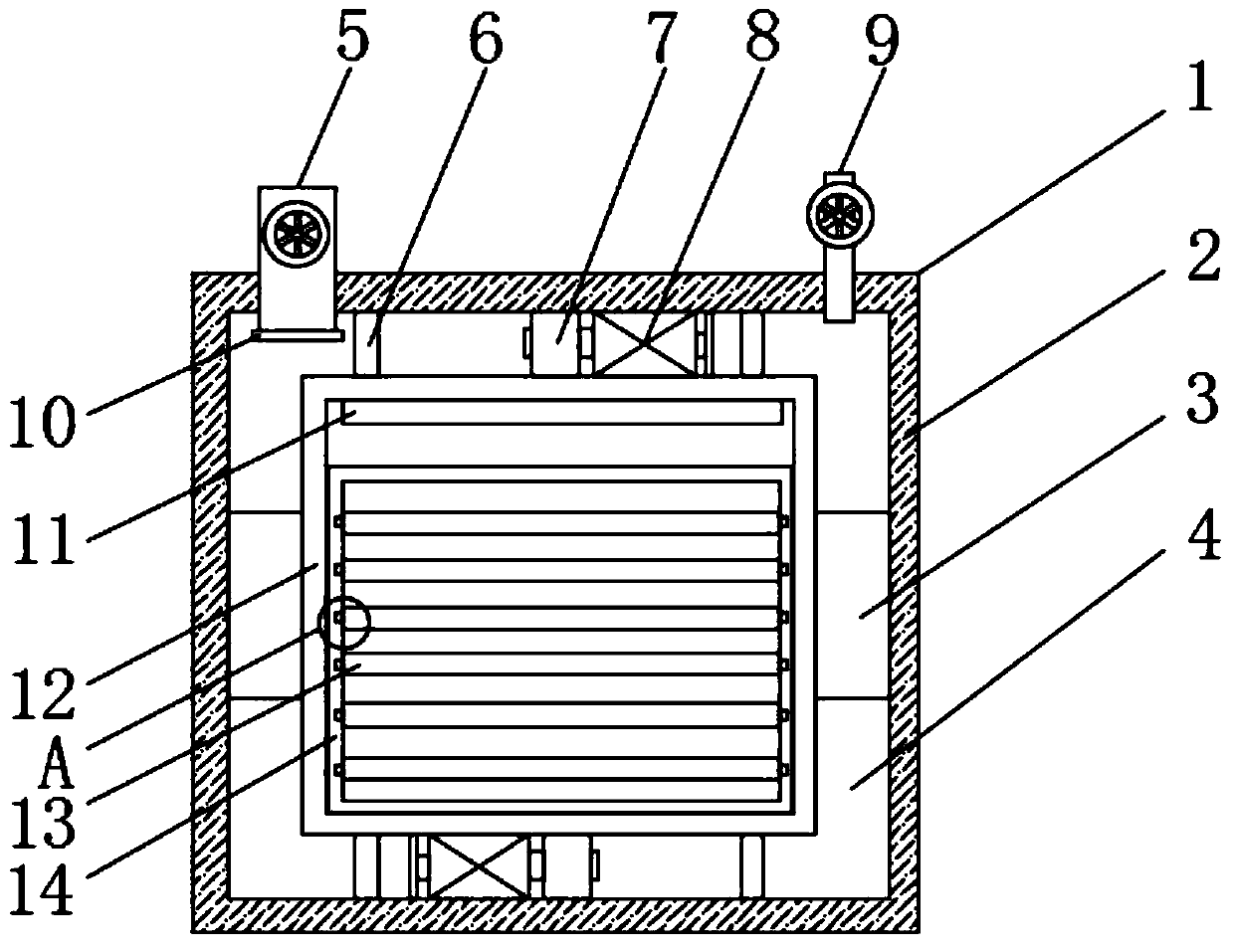

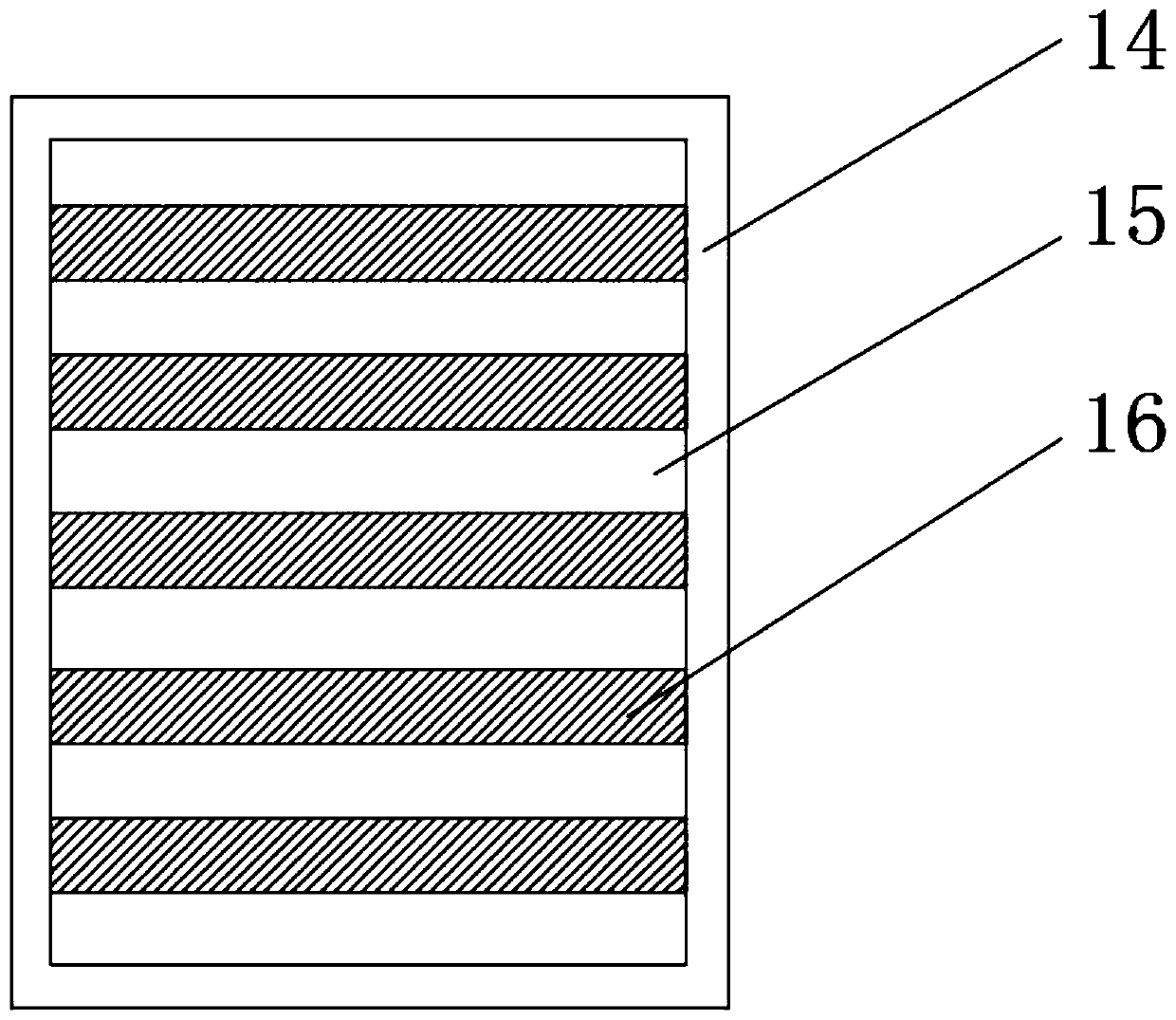

[0051] see Figure 1-7 As shown, this embodiment is a moxa mattress, including a mattress cover and a mattress core filled inside the mattress cover. The mattress cover is woven from spinning threads, and the spinning threads are mixed with a liquid mixture before being woven into a mattress cover. Dip dyeing for 10-15 minutes, the mattress core includes a moxa layer 100, and the top and bottom of the moxa layer 100 are laminated with a polyester fiber layer 200;

[0052] The liquid mixture includes the following substances by weight: 40 parts of wormwood extract, 30 parts of water-based adhesive, 1 part of fresh flower extract, 0.1 part of defoamer, 0.5 part of surfactant, and 45 parts of water;

[0053] This moxa mattress is prepared by the following steps:

[0054] Step 1: Prepare a liquid mixture: take fresh wormwood stems and leaves, mash them, add water for leaching, filter to remove impurities, and obtain wormwood leaching liquid, add water-based adhesive, disinfectant...

Embodiment 2

[0074] see Figure 1-7 As shown, this embodiment is a moxa mattress, including a mattress cover and a mattress core filled inside the mattress cover. The mattress cover is woven from spinning threads, and the spinning threads are mixed with a liquid mixture before being woven into a mattress cover. Dip dyeing for 10-15 minutes, the mattress core includes a moxa layer 100, and the top and bottom of the moxa layer 100 are laminated with a polyester fiber layer 200;

[0075] The liquid mixture includes the following substances by weight: 50 parts of wormwood extract, 35 parts of water-based adhesive, 2 parts of fresh flower extract, 0.2 part of defoamer, 1.0 part of surfactant, and 50 parts of water;

[0076]This moxa mattress is prepared by the following steps:

[0077] Step 1: Prepare a liquid mixture: take fresh wormwood stems and leaves, mash them, add water for leaching, filter to remove impurities, and obtain wormwood leaching liquid, add water-based adhesive, disinfectant...

Embodiment 3

[0097] see Figure 1-7 As shown, this embodiment is a moxa mattress, including a mattress cover and a mattress core filled inside the mattress cover. The mattress cover is woven from spinning threads, and the spinning threads are mixed with a liquid mixture before being woven into a mattress cover. Dip dyeing for 10-15 minutes, the mattress core includes a moxa layer 100, and the top and bottom of the moxa layer 100 are laminated with a polyester fiber layer 200;

[0098] The liquid mixture includes the following substances by weight: 60 parts of wormwood extract, 40 parts of water-based adhesive, 2 parts of fresh flower extract, 0.3 part of defoamer, 1.5 parts of surfactant, and 55 parts of water;

[0099] This moxa mattress is prepared by the following steps:

[0100] Step 1: Prepare a liquid mixture: take fresh wormwood stems and leaves, mash them, add water for leaching, filter to remove impurities, and obtain wormwood leaching liquid, add water-based adhesive, disinfecta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com