Application of inhibitor acrylic acid-maleic acid copolymer sodium salt in phosphate ore flotation magnesium removal

A technology of acrylic acid horse and acid copolymer, which is applied in the flotation separation of salt minerals and the flotation and demagnesization of phosphate rock, can solve the problem of low separation efficiency of apatite and dolomite, affecting the comprehensive utilization of low-grade phosphate rock. , the problem of high magnesium impurity content in phosphate concentrates, to achieve good selective inhibition, easy commercial acquisition, and improve the effect of sorting indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

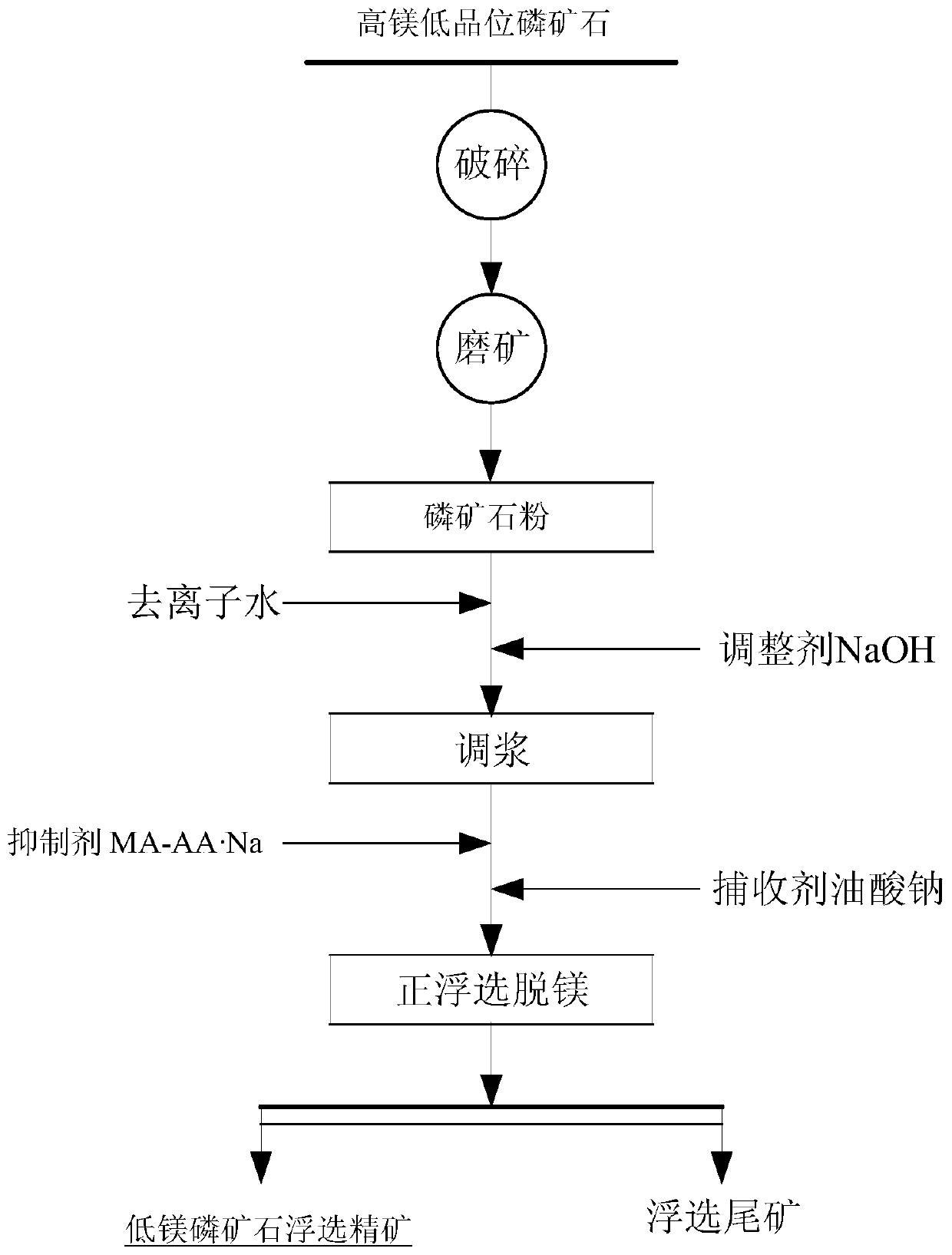

[0044] The application of a kind of inhibitor acrylic acid maleic acid copolymer sodium salt in phosphate rock flotation demagnesia, the process flow chart of its implementation is as follows figure 1 As shown, it specifically includes the following steps:

[0045] Step 1: Grinding

[0046] The high-magnesium and low-grade phosphate ore lumps are crushed by the jaw crusher and then by the roller crusher to less than 2mm, and then ground by a ceramic ball mill to obtain phosphate rock powder; among them, for phosphate rock powder , the mass of phosphate rock powder less than 74 μm accounts for 70% of the total mass of phosphate rock powder;

[0047] Step 2: Blending

[0048] Under the condition of 22°C, put the above-mentioned phosphate rock powder into the flotation equipment-flotation machine, add deionized water, stir and adjust the slurry for 2 minutes, and obtain the phosphate rock slurry; wherein, in the phosphate rock slurry, the phosphate rock The mass percentage con...

Embodiment 2

[0055] The application of a kind of inhibitor acrylic acid maleic acid copolymer sodium salt in phosphate rock flotation demagnesia, specifically comprises the following steps:

[0056] Step 1: Grinding

[0057] The high-magnesium and low-grade phosphate ore lumps are crushed by the jaw crusher and then by the roller crusher to less than 2mm, and then ground by a ceramic ball mill to obtain phosphate rock powder; among them, for phosphate rock powder , the mass of phosphate rock powder less than 74 μm accounts for 80% of the total mass of phosphate rock powder;

[0058] Step 2: Blending

[0059] Under the condition of 23°C, put the above-mentioned phosphate rock powder into the flotation equipment-flotation machine, add deionized water, stir and adjust the slurry for 2 minutes, and obtain the phosphate rock slurry; wherein, in the phosphate rock slurry, the phosphate rock The mass percentage concentration is 25%; then add a strong alkali NaOH aqueous solution with a mass per...

Embodiment 3

[0066] The application of a kind of inhibitor acrylic acid maleic acid copolymer sodium salt in phosphate rock flotation demagnesia, specifically comprises the following steps:

[0067] Step 1: Grinding

[0068] The high-magnesium and low-grade phosphate ore lumps are crushed by the jaw crusher and then by the roller crusher to less than 2mm, and then ground by a ceramic ball mill to obtain phosphate rock powder; among them, for phosphate rock powder , the mass of phosphate rock powder particles smaller than 74 μm accounts for 75% of the total mass of phosphate rock powder;

[0069] Step 2: Blending

[0070] Under the condition of 20°C, put the above-mentioned phosphate rock powder into the flotation equipment-flotation machine, add deionized water, stir and adjust the slurry for 2 minutes, and obtain the phosphate rock slurry; wherein, in the phosphate rock slurry, the phosphate rock The mass percentage concentration is 30%; then add a strong alkali NaOH aqueous solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com