Gearbox parking gear manufacturing method

A parking gear and manufacturing method technology, applied in the field of gear precision machining, can solve the problems affecting the impact resistance and bending strength of parts, high investment cost of broaching and broaching equipment, and reduced parking tooth profile accuracy. Improves material utilization, preserves integrity, reduces thermal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

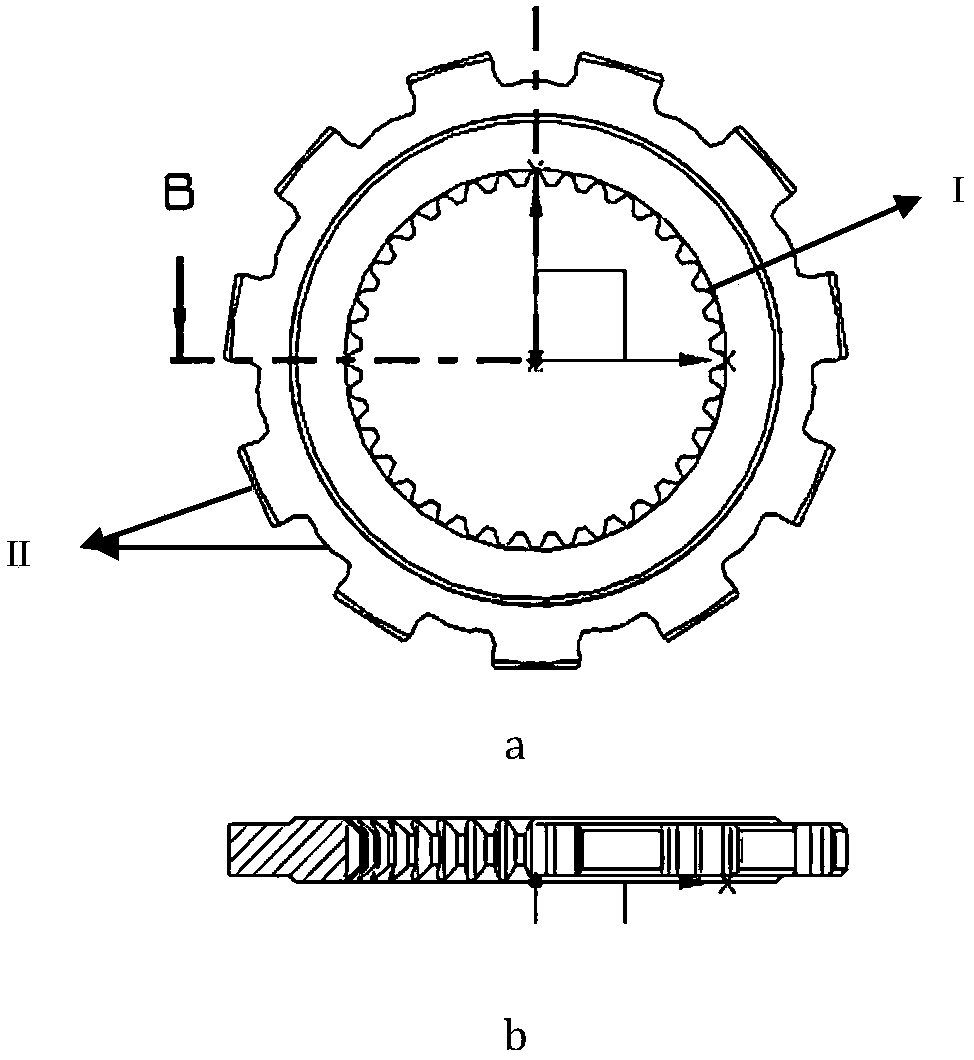

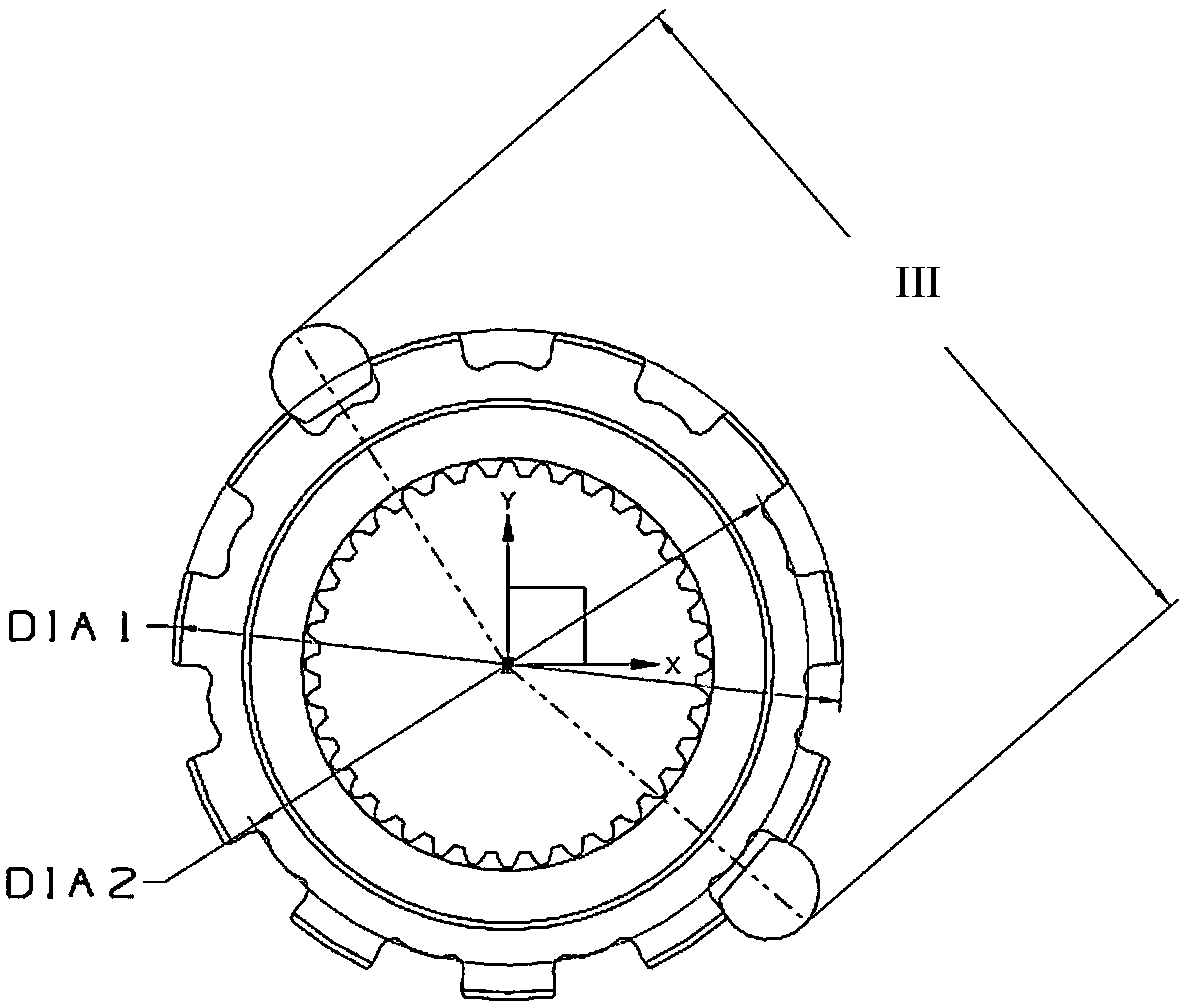

[0029] like figure 1 and figure 2 As shown, this embodiment takes the parking gear in a new energy vehicle transmission as an example to illustrate the manufacturing process of the parking gear parts. This embodiment includes the following steps:

[0030] The raw material is medium-carbon high-quality alloy structural steel, the preferred grade is SAE1552M, the carbon content is 0.52%, and the manganese content is 1.35%. The raw material steel rod is polished, and the surface has no decarburization and micro-cracks.

[0031] Blanking: Calculate the weight of the blanking according to the parts and losses, and use the sawing method to control the height-to-diameter ratio of the steel rod to 1.95; after blanking, the surface of the parts is shot peened to remove surface oxidized impurities and defects;

[0032] Heating: divided into preheating-spraying graphite-heating three-stage heating, the surface of the parts is sprayed with water-based graphite to prevent surface decarbu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com