Preparation process of an explosion-proof and radiation-proof double-layer composite mobile phone protective film

A preparation process and anti-radiation technology, which is applied to coatings, flat products, and other household appliances, etc., can solve the problems of affecting visual clarity and perception, lowering the readability of touch panels, and reducing the usability of equipment, etc., to achieve compatibility Poor performance, enhanced anti-fingerprint performance, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

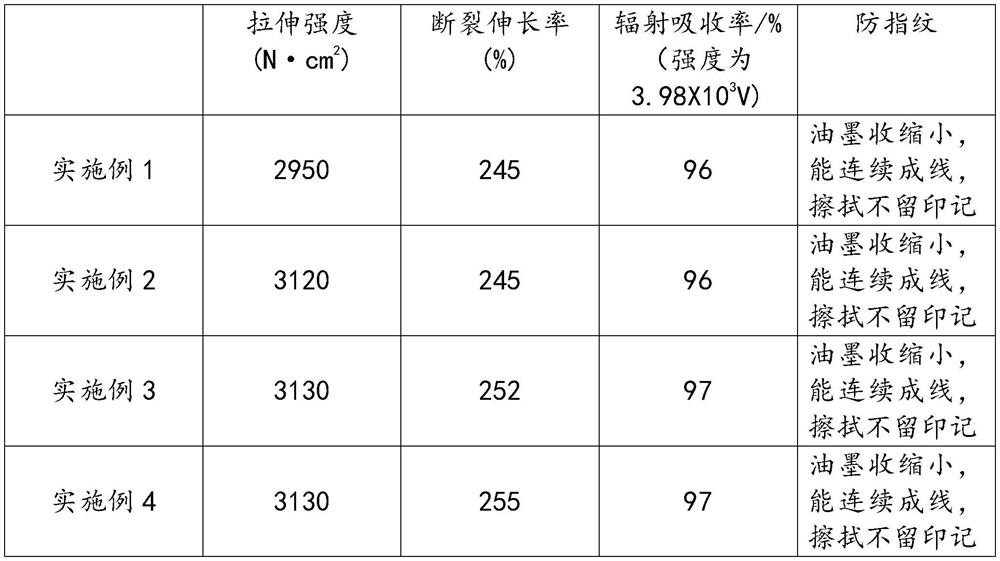

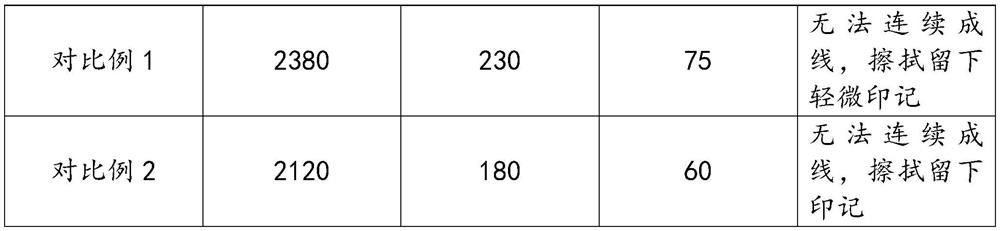

Examples

Embodiment 1

[0034] A preparation process of an explosion-proof and radiation-proof double-layer composite mobile phone protective film, the protective film includes an anti-fingerprint layer and a radiation-proof substrate layer, and the preparation process of the protective film comprises the following steps:

[0035] The first step, the preparation of the anti-radiation substrate layer:

[0036] Step S1, weighing the following raw materials by weight: 5 parts of graphene oxide / silicon nitride composite particles, 2 parts of butadiene, 10 parts of styrene, 10 parts of acrylate, 5 parts of simethicone, 25 parts of ethylene glycol , 1 part of KH550, 0.2 part of lauroyl peroxide, 3 parts of polyether ether ketone powder, 15 parts of acetonitrile, 0.1 part of PEG400;

[0037] Step S2, dissolving polyetheretherketone powder in acetonitrile, adding PEG400, stirring at a constant speed for 15 minutes, casting to form a film, drying at 60°C for 5 hours, cooling to room temperature, immersing in ...

Embodiment 2

[0049] A preparation process of an explosion-proof and radiation-proof double-layer composite mobile phone protective film, the protective film includes an anti-fingerprint layer and a radiation-proof substrate layer, and the preparation process of the protective film comprises the following steps:

[0050] The first step, the preparation of the anti-radiation substrate layer:

[0051] Step S1. Weigh the following raw materials in parts by weight: 8 parts of graphene oxide / silicon nitride composite particles, 3 parts of butadiene, 12 parts of styrene, 14 parts of acrylate, 6 parts of dimethyl silicone oil, 26 parts of ethylene glycol Alcohol, 3 parts of KH550, 0.4 parts of lauroyl peroxide, 4 parts of polyether ether ketone powder, 18 parts of acetonitrile, 0.2 parts of PEG400;

[0052] Step S2, dissolving polyetheretherketone powder in acetonitrile, adding PEG400, stirring at a constant speed for 15 minutes, casting to form a film, drying at 60°C for 5 hours, cooling to room ...

Embodiment 3

[0058] A preparation process of an explosion-proof and radiation-proof double-layer composite mobile phone protective film, the protective film includes an anti-fingerprint layer and a radiation-proof substrate layer, and the preparation process of the protective film comprises the following steps:

[0059] The first step, the preparation of the anti-radiation substrate layer:

[0060] Step S1. Weigh the following raw materials in parts by weight: 8 parts of graphene oxide / silicon nitride composite particles, 4 parts of butadiene, 14 parts of styrene, 18 parts of acrylate, 8 parts of simethicone, and 28 parts of ethylene glycol , 4 parts of KH550, 0.6 parts of lauroyl peroxide, 4 parts of polyether ether ketone powder, 22 parts of acetonitrile, 0.2 parts of PEG400;

[0061] Step S2, dissolving polyetheretherketone powder in acetonitrile, adding PEG400, stirring at a constant speed for 15 minutes, casting to form a film, drying at 60°C for 5 hours, cooling to room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com