a kind of wo 3 Electrochromic thin film and preparation method thereof

An electrochromic and thin-film technology, applied in the direction of coating, etc., can solve the problems that the discoloration performance of amorphous tungsten oxide thin film cannot be fully utilized, the cost of precursor and solvent is high, and the electrochromic performance is affected, and the electrochromic performance can be achieved. Good performance, saving annealing time, high solution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix nano-tungsten oxide (purity: 99.8%, McLean) and concentrated ammonia (mass fraction: 25%, Guangzhou Chemical) in a mass ratio of 1:4;

[0031] (2) placing the solution obtained in step (1) on a magnetic stirring table and stirring for 24h;

[0032] (3) the solution obtained in step (2) is treated by ultrasonic vibration for 10min;

[0033] (4) the solution obtained in step (3) is adjusted to pH 12 with concentrated ammonia to obtain a precursor solution;

[0034] (5) In the glove box, spin-coating the prepared thin film on the cleaned ITO glass substrate. First rotate the substrate at 1500 rpm, and then drop the precursor solution onto the surface of the rotating substrate at a drop rate of 10 μL / s until the solution completely covers the entire substrate, stop dripping the solution, and then adjust the spin coating speed to 3000rpm, continuous spin coating for 60s;

[0035] (6) pre-annealing the film obtained in step (5) at a temperature of 120° C. for 10 mi...

Embodiment 2

[0041] The steps of (1)-(4) solution treatment and (6)-(7) annealing treatment in Example 1 are the same, except that in step (5): in the glove box, spin on the cleaned ITO glass substrate. Coating to prepare thin films. First rotate the substrate at 2000 rpm, then drop the precursor solution onto the surface of the rotating substrate at a drop rate of 10 μL / s until the solution completely covers the entire substrate, stop dripping the solution, and then adjust the spin coating speed to 4000rpm, continuous spin coating for 90s.

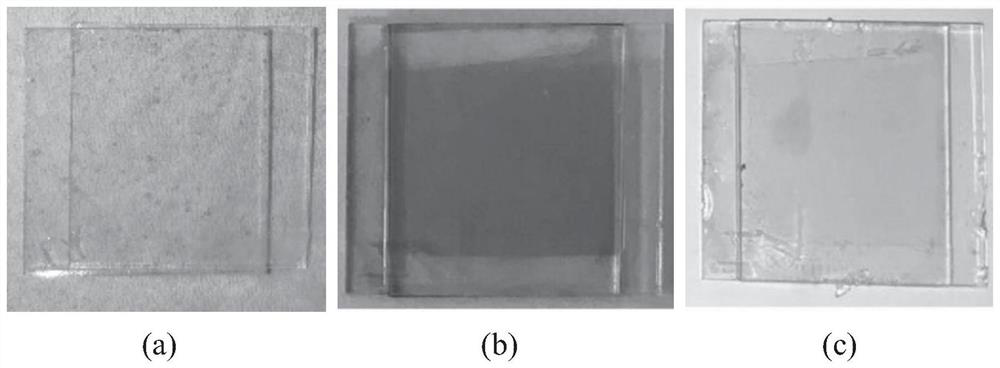

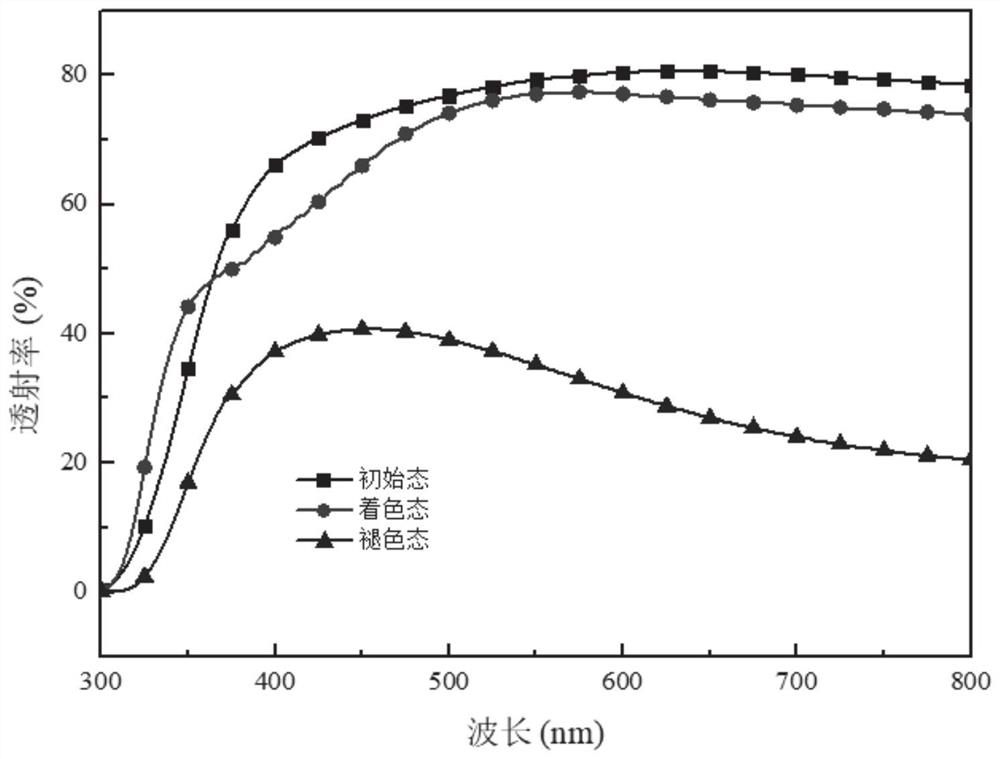

[0042] The resulting film thickness was 52.5±5 nm. The film obtained in Example 2 was subjected to an electrochromic test. 3 The photo of film discoloration is similar to Example 1. The transmittance modulation curve relative to air is as Figure 4 shown. Figure 4The transmittance curves of the initial state, colored state and faded state of the film obtained in Example 2. Taking the wavelength of 550 nm as the reference wavelength, the initial...

Embodiment 3

[0044] The steps of (1) to (6) solution treatment and pre-annealing treatment in Example 1 are the same, except that in step (7): the film after pre-annealing in step (6) is rapidly annealed in a rapid annealing furnace in an air atmosphere , firstly heated at a heating rate of 40°C / s, maintained at 200°C for 60s, then heated at 10°C / s, maintained at 300°C for 60s, and finally lowered to room temperature at a cooling rate of 10°C / s.

[0045] Compared with Examples 1 and 2, this example adopts a lower heating rate, and the obtained film thickness is 86.2±5 nm. The electrochromic test was carried out on the film obtained in Example 3. The electrolyte was 0.5 mol / L lithium perchlorate-propylene carbonate-UV curing glue solid electrolyte, the driving voltage was 2.5 V, and the electrification time was 30 s. Taking the wavelength of 550 nm as the reference wavelength, the initial state transmittance of the film is 78.9%, the color state transmittance is 41.6% and the faded state tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

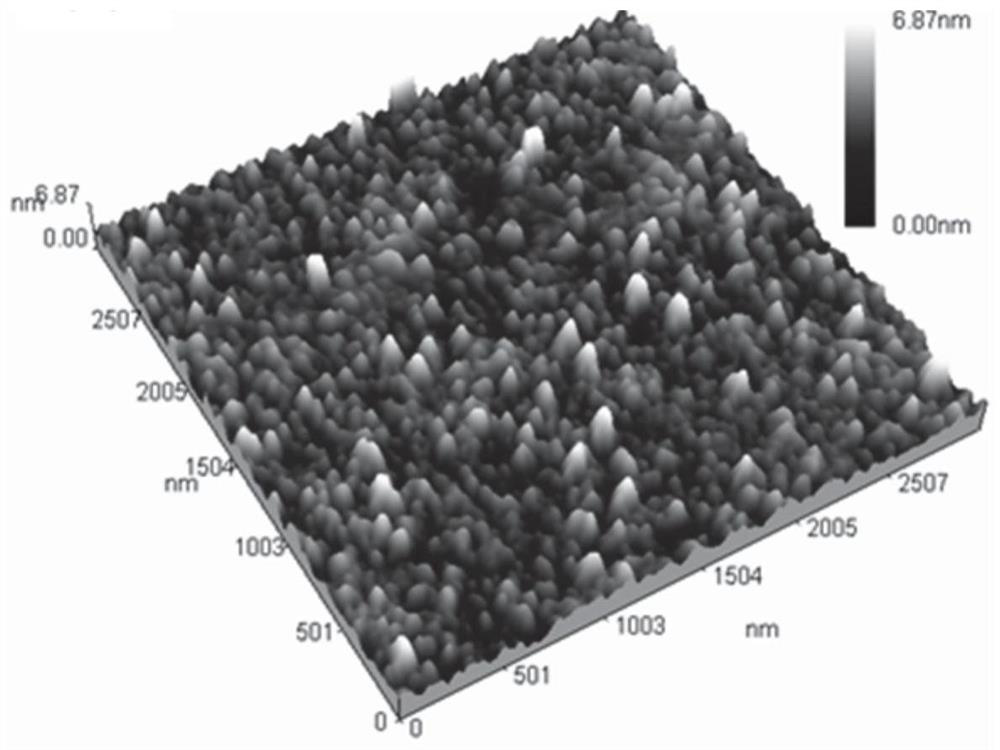

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com