Preparation method of fireproof door core plate

A technology of fire door core and magnesium sulfate, which is applied in the field of building materials, can solve the problems of shortening the service life of fire doors, corroding steel plates, absorbing moisture, etc., and achieves the effects of light bulk density, improved service life and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

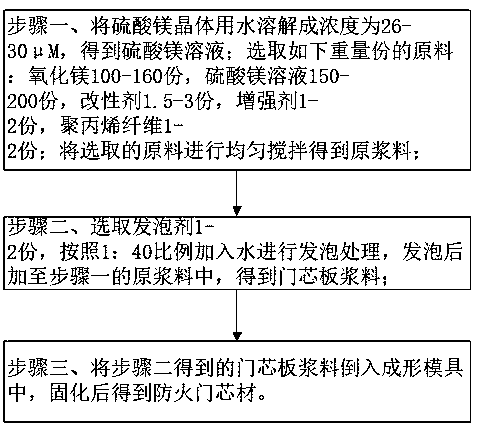

[0026] A preparation method for a fire door core material, comprising the following steps:

[0027] Step 1, dissolving magnesium sulfate crystals with water to a concentration of 26-30 μM to obtain magnesium sulfate solution; select the following raw materials in parts by weight: 100 parts of magnesium oxide, 150 parts of magnesium sulfate solution, 1.5 parts of modifier, 1 part of reinforcing agent, 1 part of polypropylene fiber; the selected raw materials are poured into a mixer and stirred evenly to obtain a raw slurry; wherein the foaming agent is a biological protein foaming agent. The modifying agent is one or more mixtures of oxalic acid, citric acid and trisodium phosphate. The reinforcing agent is silicon dioxide.

[0028] Step one is specifically:

[0029] First take 150 parts of magnesium sulfate solution, 1.5 parts of modifier, 1 part of reinforcing agent, and 1 part of polypropylene fiber and pour them into a mixer for uniform stirring; then add 100 parts of mag...

Embodiment 2

[0034] A preparation method for a fire door core material, comprising the following steps:

[0035] Step 1, dissolving magnesium sulfate crystals with water to a concentration of 26-30 μM to obtain a magnesium sulfate solution; select the following raw materials in parts by weight: 150 parts of magnesium oxide, 180 parts of magnesium sulfate solution, 1.8 parts of a modifier, 1.5 parts of a reinforcing agent, 1.5 parts of polypropylene fiber; the selected raw materials are poured into a mixer and stirred evenly to obtain a raw slurry; wherein the foaming agent is a biological protein foaming agent. The modifying agent is one or more mixtures of oxalic acid, citric acid and trisodium phosphate. The reinforcing agent is silicon dioxide.

[0036] Step one is specifically:

[0037] First take 180 parts of magnesium sulfate solution, 1.8 parts of modifier, 1.5 parts of reinforcing agent, and 1.5 parts of polypropylene fiber and pour them into a mixer for uniform stirring; then ad...

Embodiment 3

[0042] A preparation method for a fire door core material, comprising the following steps:

[0043] Step 1, dissolving magnesium sulfate crystals with water to a concentration of 26-30 μM to obtain magnesium sulfate solution; select the following raw materials in parts by weight: 160 parts of magnesium oxide, 200 parts of magnesium sulfate solution, 3 parts of modifier, 2 parts of reinforcing agent, 2 parts of polypropylene fibers; the selected raw materials are poured into a mixer for uniform stirring to obtain raw slurry; wherein the foaming agent is a biological protein foaming agent. The modifying agent is one or more mixtures of oxalic acid, citric acid and trisodium phosphate. The reinforcing agent is silicon dioxide.

[0044] Step one is specifically:

[0045] First take 200 parts of magnesium sulfate solution, 3 parts of modifier, 2 parts of reinforcing agent, and 2 parts of polypropylene fiber, pour them into a mixer and stir evenly; then add 160 parts of magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com