Organic eutectic gain material and preparation method and application thereof in laser performance

An organic and organic solvent technology, applied in the field of new organic eutectic gain material and its preparation method, and its application in laser performance, can solve the problems such as difficult to obtain optical gain, and achieve the effect of improving laser performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

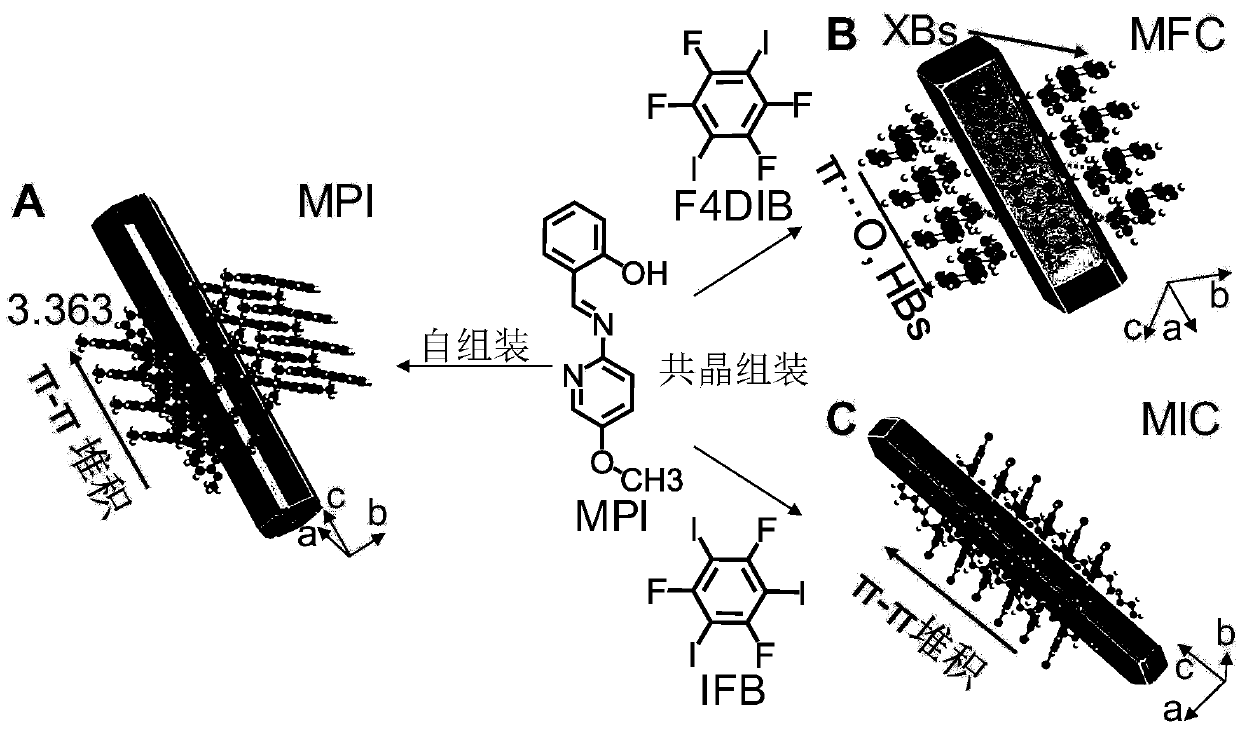

[0059] Preparation example 1 Preparation of laser dye molecule MPI

[0060] Compound MPI shown in the synthetic formula (1 ') according to the following route:

[0061] Its specific preparation process is as follows:

[0062] Dissolve 2.615 ml of salicylaldehyde in 10 ml of ethanol and set aside. 3.103 g of 2-amino-5-methoxypyridine were dissolved in 30 ml of ethanol and mixed with the above salicylaldehyde solution. The mixed solution was refluxed for 2 hours. After the reaction, the mixed solution was cooled to room temperature and filtered to obtain the product. The product was washed with deionized water and dried under vacuum. Further recrystallization of the product (from hot ethanol solution) can give yellow needle-like crystals, namely MPI.

[0063]

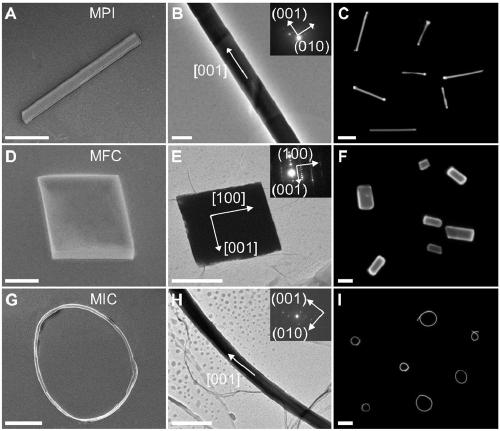

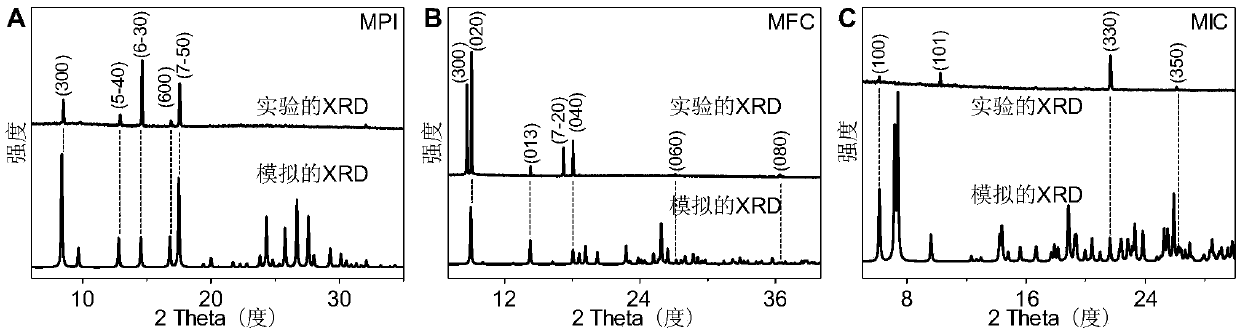

Embodiment 1

[0065] The specific preparation process of the organic eutectic gain material MFC is as follows:

[0066] 1) The compounds MPI and halobenzene F4DIB prepared in Preparation Example 1 were dissolved in acetonitrile solvent respectively to obtain an MPI acetonitrile solution with a concentration of 5mmol / L and a F4DIB acetonitrile solution with a concentration of 5mmol / L;

[0067] 2) The above-mentioned MPI acetonitrile solution with a concentration of 5mmol / L and the F4DIB acetonitrile solution with a concentration of 5mmol / L are fully mixed according to the molar ratio of MPI and F4DIB being 2:1 to obtain a two-component mixed system;

[0068] 3) Add 20 μL of the mixed solution prepared in step 2) dropwise on a glass slide, and place it in a n-hexane atmosphere. After the acetonitrile solvent is completely evaporated, a microsheet structure can be obtained, which is denoted as MFC.

[0069] The MFC prepared in Example 1 can be used in the field of organic micro-nano lasers due...

Embodiment 2

[0071] The specific preparation process of the organic eutectic gain material MIC is as follows:

[0072] 1) The compound MPI and halogenated benzene IFB prepared in Preparation Example 1 were dissolved in acetonitrile solvent respectively to obtain an MPI acetonitrile solution with a concentration of 5 mmol / L and an IFB acetonitrile solution with a concentration of 5 mmol / L;

[0073] 2) The above-mentioned MPI acetonitrile solution with a concentration of 5mmol / L and the IFB acetonitrile solution with a concentration of 5mmol / L are fully mixed according to the molar ratio of MPI and IFB as 1:1 to obtain a two-component mixed system;

[0074] 3) Add 20 μL of the mixed solution prepared in step 2) dropwise on a glass slide, and place it in a n-hexane atmosphere. After the acetonitrile solvent is completely evaporated, a microring structure can be obtained, which is recorded as MIC.

[0075] The MIC prepared in Example 2 can be used in the field of organic micro-nano lasers due ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com