Porous silica light diffusion agent with polymethyl methacrylate bonded on surface, and preparation method thereof

A technology of polymethyl methacrylate and porous silica, applied in the direction of silica, silicon oxide, etc., can solve the problems of unstable optical properties, brittleness, etc., and achieve improved brightness, light transmittance, and good weather resistance , Energy-saving and high-efficiency glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

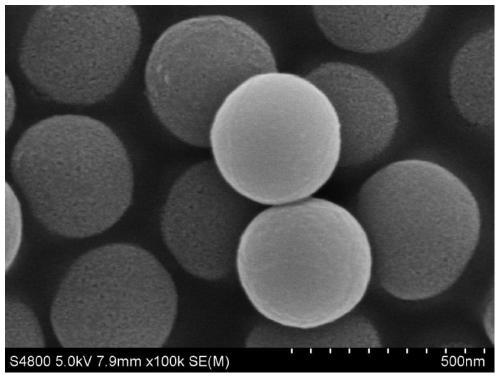

[0019] The preparation method of the porous silica light-diffusing agent of the surface-linked polymethyl methacrylate comprises the following steps:

[0020] (1) Under the condition of stirring at 25-45 degrees, add ammonia water and tetraethoxysilane to the mixed solution of water and ethanol, continue to react for 2-4 hours, wash and dry, and prepare silica pellets, wherein, The volume ratio of the tetraethoxysilane volume to water is 1:4-1:8, the volume ratio of the tetraethoxysilane volume to ethanol is 1:8-1:20, the tetraethoxysilane The volume ratio of silane volume to ammonia water is 1:2-1:6;

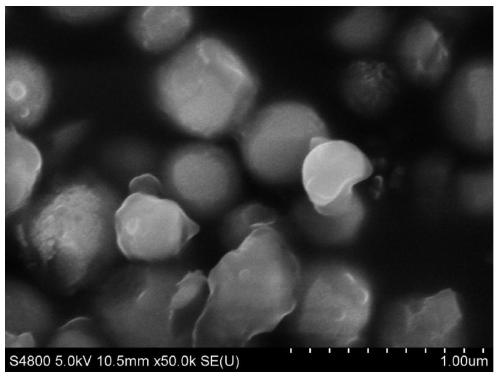

[0021] (2) Take the silica pellets prepared in step (1) in deionized water to prepare a mixed solution with a mass fraction of 3-50 wt%, and ultrasonically disperse it for 30 minutes; under stirring conditions, add a certain amount of surfactant agent, reacted for 1-3 hours; under stirring conditions, continue to add alkaline substances to the mixed solution, and control the c...

Embodiment 1

[0025] Under the condition of stirring at 35 degrees, 8 milliliters of ammonia water and 2 milliliters of tetraethoxysilane were added to the mixed solution of 8 milliliters of water and 40 milliliters of ethanol, and the reaction was continued for 3 hours and then washed and dried to obtain silica pellets; The above 0.4 g of silica pellets were dispersed in 10 ml of deionized water by ultrasonic for 30 minutes; under stirring conditions, 20 mg of cetyltrimethylammonium bromide was added and reacted for 2 hours; under stirring conditions, continue to 0.8 g of sodium hydroxide was added to the mixture. After continuing to react for 5 hours, the sample was washed and dried, and the sample was calcined at 450° C. for 3 hours to obtain superficially porous silica pellets; 4 g of superficially porous silica pellets were dissolved in 200 ml of toluene. Add 2 ml of 3-methacryloxypropyltrimethoxysilane as a silane coupling agent, reflux in an oil bath at 120 degrees for 8 hours, wash ...

Embodiment 2

[0027]Under the condition of stirring at 35 degrees, 8 milliliters of ammonia water and 2 milliliters of tetraethoxysilane were added to the mixed solution of 8 milliliters of water and 40 milliliters of ethanol, and the reaction was continued for 3 hours and then washed and dried to obtain silica pellets; The above 0.4 g of silica pellets were dispersed in 10 ml of deionized water by ultrasonic for 30 minutes; under stirring conditions, 30 mg of cetyltrimethylammonium bromide was added and reacted for 2 hours; under stirring conditions, continue to 0.8 g of sodium hydroxide was added to the mixture. After continuing to react for 5 hours, the sample was washed and dried, and the sample was calcined at 450° C. for 3 hours to obtain superficially porous silica pellets; 4 g of superficially porous silica pellets were dissolved in 200 ml of toluene. Add 2 ml of 3-methacryloxypropyltrimethoxysilane as a silane coupling agent, reflux in an oil bath at 120 degrees for 8 hours, wash t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com