Well mouth casing gas pressurizing recovery device, system and method and application

A technology of recovery device and booster device, which is applied in earthwork drilling, wellbore/well components, liquid variable capacity machinery, etc., and can solve problems such as inability to recover casing gas, difficulty in low temperature operation, and increased power consumption , to achieve the effect of shortening the time rate of finding abnormal oil wells, reducing the labor intensity of employees, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

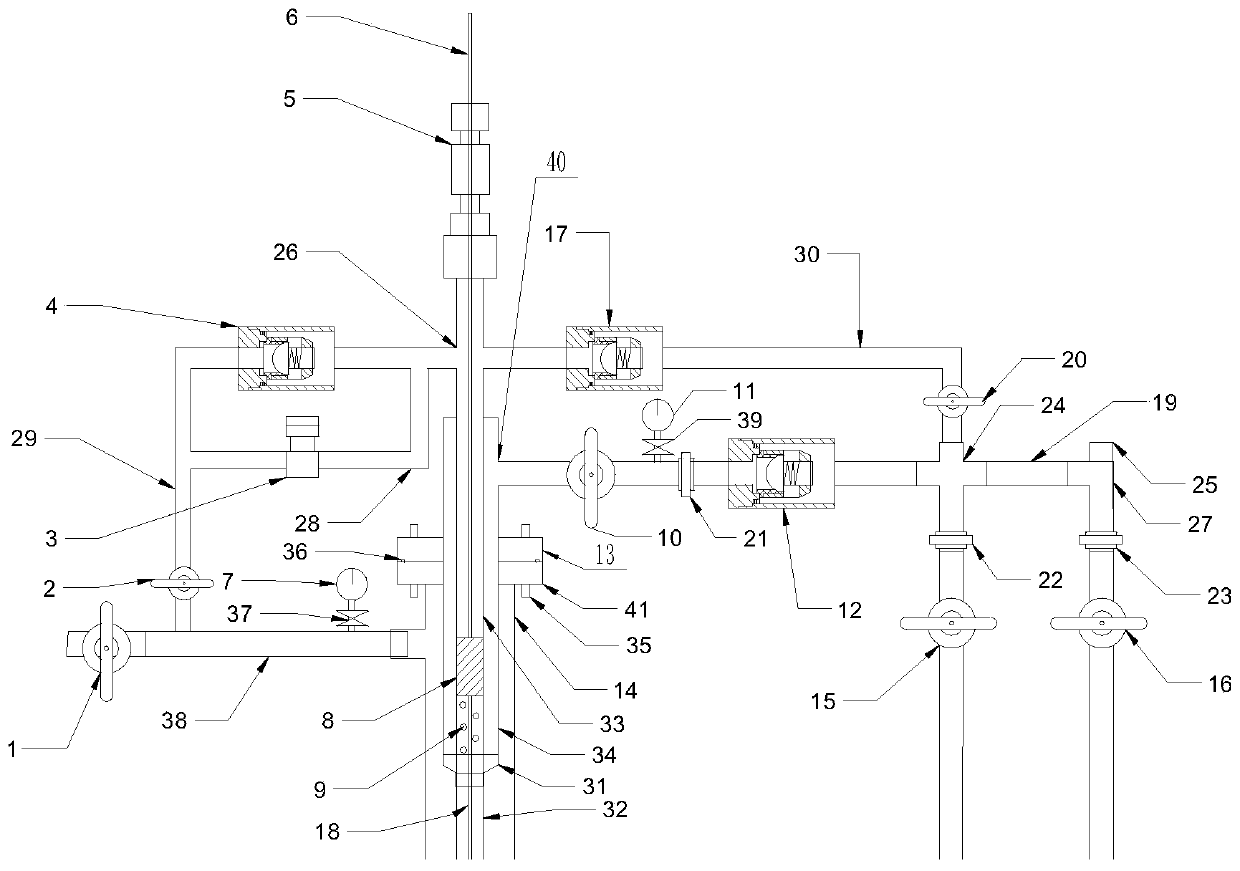

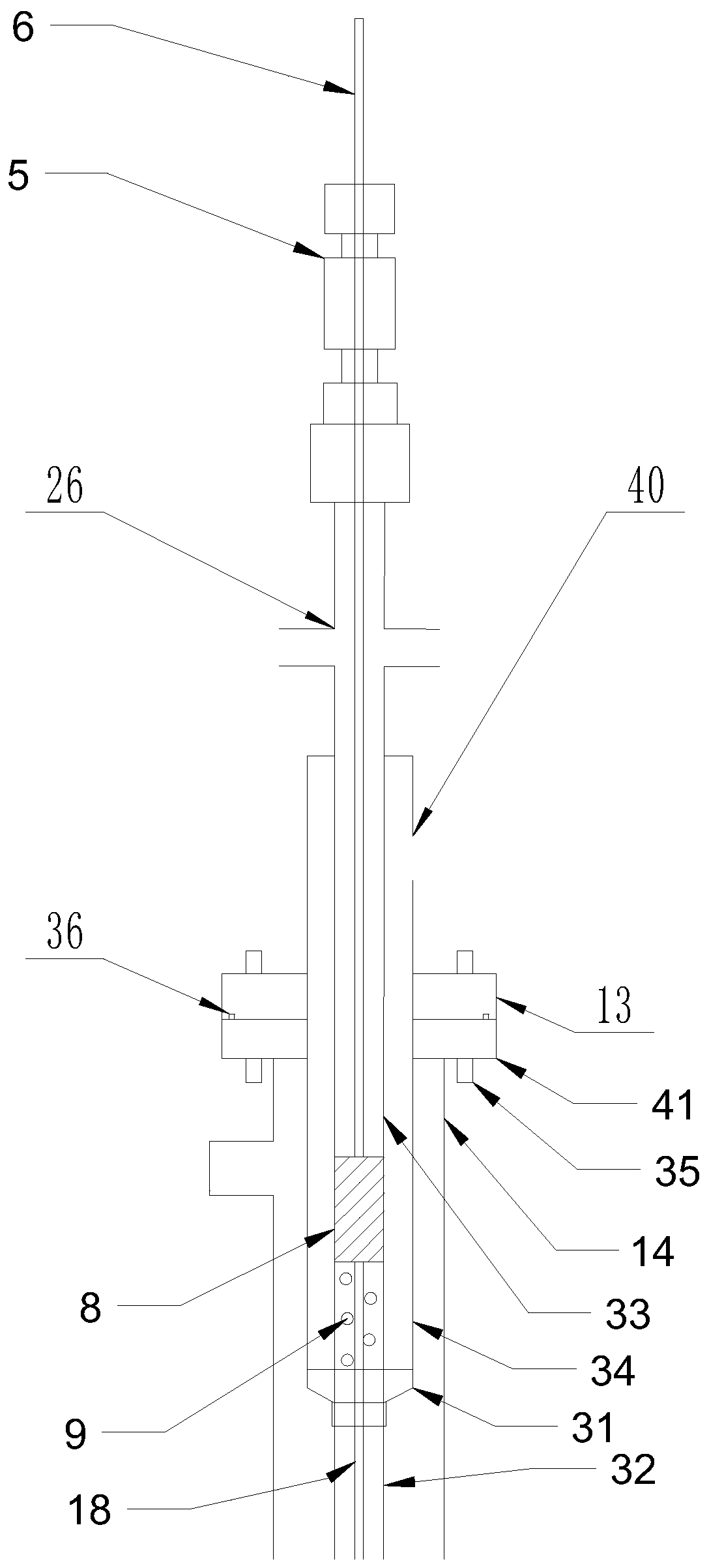

[0041] according to figure 1 The shown oil well casing gas pressurized recovery device includes a polished rod sealer 5, a polished rod 6, a wellhead cross 26, a built-in plunger 8 of the pressurized device, a screen tube 9, a variable diameter collar 31, a work cylinder 33, The sleeve 34 and the sucker rod 18; the polished rod sealer 5 is connected to the work cylinder 33 through the wellhead spool 26; the polished rod 6 extends into the work cylinder 33 through the polished rod sealer 5, and is placed in the work cylinder 33 The pressurization device inside is connected with a built-in plunger 8, and the screen tube 9 is connected to the lower part of the working cylinder 33; the sleeve 34 is connected to the outside of the working cylinder 33 and the screen tube 9, and the lower port of the sleeve 34 passes through a reducing collar 31 It is connected with the lower port of the screen tube 9, the outer wall of the sleeve 34 is provided with a connecting piece, and the upper...

Embodiment 2

[0046] according to figure 1 The shown oil well casing gas pressurized recovery device is different from the first embodiment in that the connector provided on the outer wall of the sleeve 34 is the first flange 13, and the lower surface of the first flange 13 is opened. There are grooves.

[0047] In actual use, the connecting piece on the outer side wall of the sleeve 34 adopts the technical scheme of the first flange 13, which can easily connect the oil well casing gas pressurized recovery device and the oil pipe 32 through the flange screw 35, which is low in cost and has Better connection effect. The groove on the lower surface of the first flange 13 is used for placing the sealing steel ring 36 to ensure a good sealing effect.

Embodiment 3

[0049] according to figure 1 The shown oil well casing gas pressurized recovery system includes at least one oil well casing gas pressurized recovery device, and also includes casing gate 1, casing 14, tubing 32, casing gas pipeline 38, casing gas collection Pipeline 29, exhaust pipeline 30 and wellhead oil collection pipeline 19; the oil pipe 32 is connected to the variable diameter collar 31 of the oil well casing gas pressurization recovery device; the casing 14 is sleeved in the oil well casing gas pressurization Outside the recovery device, the upper port of the sleeve pipe 14 is connected to the connector provided on the outer side wall of the sleeve 34; connection; the input end of the casing gas collection line 29 is connected to the casing gas line 38, and the output end of the casing gas collection line 29 is connected to the wellhead cross 26; the input end of the exhaust pipeline 30 is connected to the wellhead cross 26 , the output end of the exhaust pipeline 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com