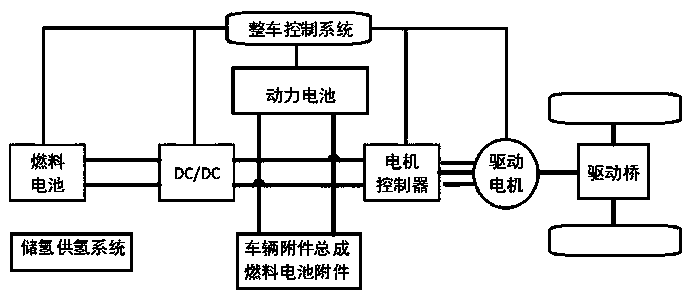

Boosted circuit of direct-hanging high-voltage power supply and soft start method

A high-voltage power supply and boost circuit technology, applied in the power supply field, can solve problems such as diode overvoltage damage, achieve the effects of reducing volume, reducing inductor volume, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

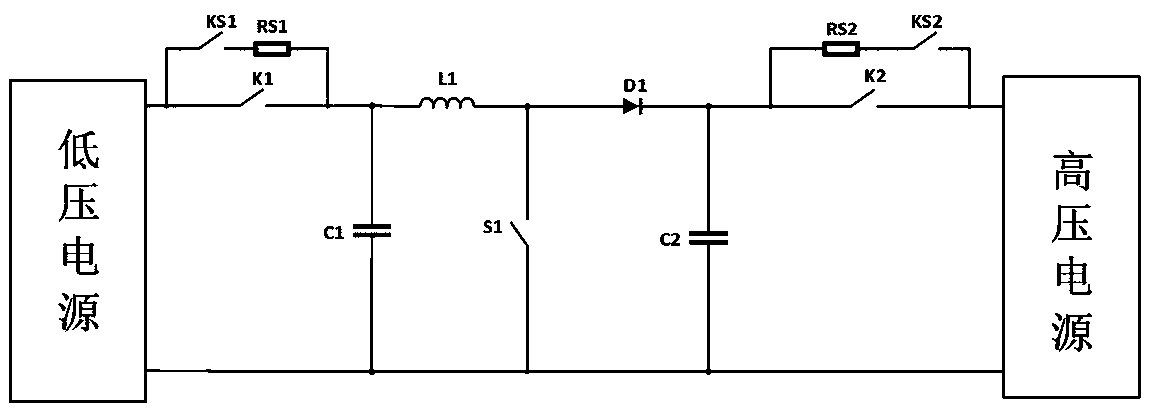

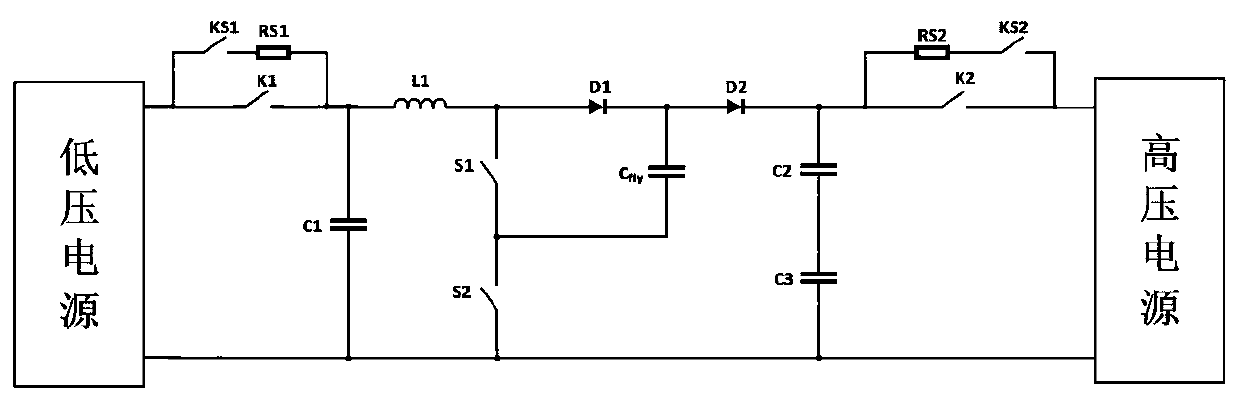

[0027] see Figure 4 , Embodiment 1: In the embodiment of the present invention, a booster circuit directly connected to a high-voltage power supply,

[0028] A booster circuit directly connected to a high-voltage power supply, comprising an inductor L1, a switch S1, a diode D1, and a diode D2, one end of the inductor L1 is connected to a capacitor C1, a switch K1, and the anode of a diode D3, and the other end of the switch K1 is connected to a low-voltage power supply , the other end of the inductor L1 is connected to the switch S1 and the anode of the diode D1, the cathode of the diode D1 is connected to the capacitor Cfly, the resistor RS3 and the anode of the diode D2, the other end of the switch S1 is connected to the switch S2 and the other end of the capacitor Cfly, and the other end of the capacitor C1 One end is connected to the other end of the switch S2, the other end of the low-voltage power supply, the capacitor C3 and the high-voltage power supply, the cathode o...

Embodiment 2

[0030] Embodiment 2: on the basis of embodiment 1, as Figure 5 As shown, KS3 and D4 are added, among which KS3 is a normally closed switch. When the control system is powered on, the host sends a power-on command, and the power supply enters the start-up state. First, KS2 is closed, and the high-voltage power supply is charged through KS2, RS2 and C2, C3. At the same time, the high-voltage power supply forms a charging circuit through KS2, RS2, KS3, Cfly and C3, until the system detects that the voltages of C2, C3 and Cfly meet the starting voltage, close K2, and disconnect KS2 and KS3 at the same time, at this time due to C2 The voltage is the same as that of Cfly, so there is no loss in the disconnection of KS3, and the DCDC power supply and the high voltage power supply side are hung together. Then close KS1, and the low-voltage power supply side charges C1 through KS1 and RS1. Similarly, when it is detected that the voltage of C1 meets the starting conditions, close K1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com