Self-circulation filtering method in solid waste pyrolysis incineration

A filtration method and self-circulation technology, applied in the combustion method, separation method, dispersed particle filtration, etc., to achieve the effect of ensuring cleanliness, ensuring air permeability, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing:

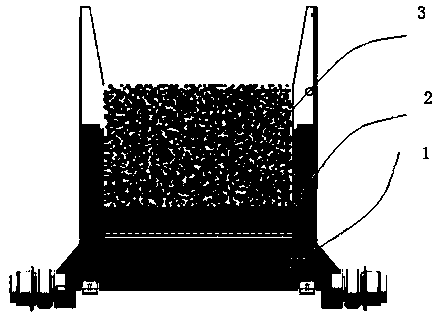

[0016] The self-circulation filtration method in the solid waste pyrolysis incineration proposed by the present invention is used in the pyrolysis incineration process of the solid waste pyrolysis incineration system. The method is that the residue obtained after pyrolysis and incineration is crushed by the crushing section, and then circulated to the cloth section, where it is laid on the bottom of the incineration unit 1 as a base material, used as the filter layer 2 of the incineration unit, and then clothed on the filter layer Incineration material 3, the material to be incinerated can be waste incineration fly ash, chemical waste salt, organic silicon slurry residue, oil sludge, domestic sludge, chemical sludge, printing and dyeing sludge, rectification residue, leather sludge, electroplating sludge, chromium slag and other solid waste, such as figure 1 shown.

[0017] In this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com