Method for preparing spherical solid defoaming agent through micro-channel

A technology of solid defoamer and microchannel, which is applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve the problems of large particle size difference, high carrier density requirements, low yield, etc., and achieve excellent Anti-foam performance, reduce curing time, avoid the effect of intermittent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

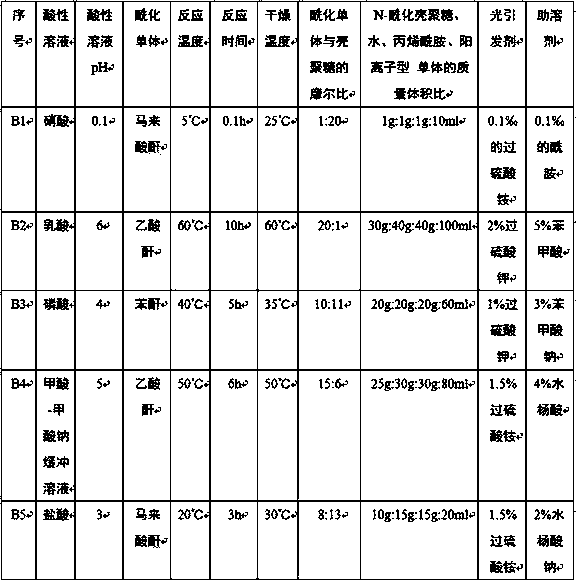

preparation example Construction

[0021] The preparation example of oil phase defoamer composition

[0022] The oil phase defoamer composition A1 was prepared by using the silicone active material and octylphenol polyoxyethylene ether prepared by the technology in Example 1 of patent CN103804834B at a mass ratio of 1:1.

[0023] The oil phase defoamer composition A2 was prepared by using the organosilicon active material prepared by the patent CN103804834B Example 2 technology and the branched isomeric tridecyl fatty alcohol polyoxyethylene ether at a mass ratio of 1:10.

[0024] The oil phase defoamer composition A3 was prepared by using the silicone active material and polyoxyethylene laurate prepared by the technology of Example 3 of patent CN103804834B at a mass ratio of 10:1.

[0025] The oil phase defoamer composition A4 was prepared by using the silicone active material and sorbitan tristearate prepared by the technology in Example 4 of patent CN103804834B at a mass ratio of 3:8.

[0026] The oil phase...

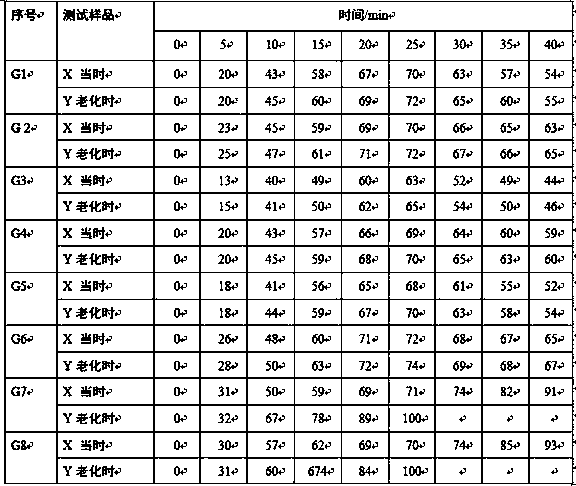

Embodiment 1

[0038] First pump the water-phase chitosan solution B1 and the oil-phase defoamer composition A1, F into the microstructure channel with an inner diameter of 500 μm A=20μL / min, the flow rate ratio of the two is F B :F A =10:1, form a stable O / W emulsion; then pump into the oil phase emulsifier C1, the flow rate ratio F C :(F B +F A ) = 10:1, forming a stable O / W / O emulsion into the microchannel extension tube with an inner diameter of 700 μm, which is made of polyethylene. The emulsion was subjected to photoinitiated polymerization for 5 min under ultraviolet light irradiation. After the reaction, the solid and liquid are automatically separated, and the chitosan solid on the filter net is washed and dried to obtain the spherical chitosan-based solid defoamer G1.

Embodiment 2

[0040] First, the water phase chitosan solution B2 and the oil phase defoamer composition A2, F are pumped into the microstructure channel with an inner diameter of 10 μm A =5μL / min, the flow rate ratio of the two is F B :F A =5:1, forming a stable O / W emulsion; then pump into the oil phase emulsifier C2, the flow rate ratio F C :(F B +F A ) = 5:1, forming a stable O / W / O emulsion into a microchannel extension tube with an inner diameter of 200 μm, which is made of polypropylene. The emulsion was subjected to photoinitiated polymerization for 1 min under ultraviolet light irradiation. After the reaction, the solid and liquid are automatically separated, and the chitosan solid on the filter net is washed and dried to obtain the spherical chitosan-based solid defoamer G2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com