Preparation method and application of bimetallic oxide loaded activated carbon fiber composite electrode

A bimetallic oxide, activated carbon fiber technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of poor pollutant degradation ability and sulfate activation efficiency It can overcome the problems of low activation efficiency and low activation efficiency, and achieve the effect of overcoming the difficulty of uniformity and easy falling off, improving efficiency and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

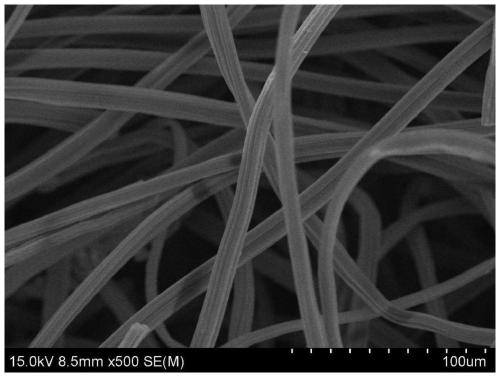

[0024] (1) The activated carbon fibers (2×5cm) are soaked and cleaned with nitric acid (1M), sodium hydroxide (1M) and deionized water in turn to remove organic impurities and inorganic impurities on the surface of the activated carbon fibers, and dried for later use;

[0025] (2) The prepared CuFe 2 O 4 The powder is washed 3 to 4 times with absolute ethanol and deionized water, centrifuged to remove impurities, and dried for later use;

[0026] (3) adding a certain amount of PTFE emulsion to deionized water to obtain a 0.1wt% PTFE aqueous solution;

[0027] (4) 0.1 g of CuFe treated in step (2) 2 O 4 The powder was added to the PTFE solution prepared in step (3), and ultrasonicated for 10 min to obtain 0.5wt% uniform CuFe 2 O 4 Dispersions;

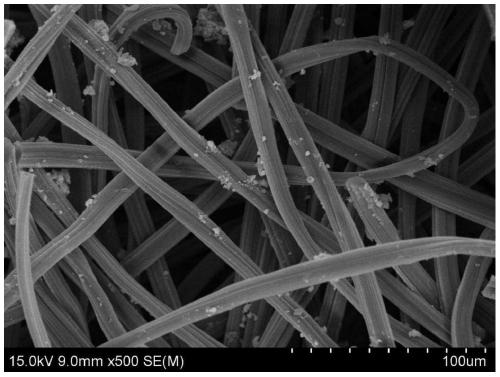

[0028] (5) adding the activated carbon fiber treated in step (1) to the CuFe obtained in step (4) 2 O 4 In the dispersion liquid, the water bath was shaken for 15min, placed in a 120 ℃ oven to dry, weighed, CuFe 2 O 4 The load...

Embodiment 2

[0030] Example 2 (comparative example)

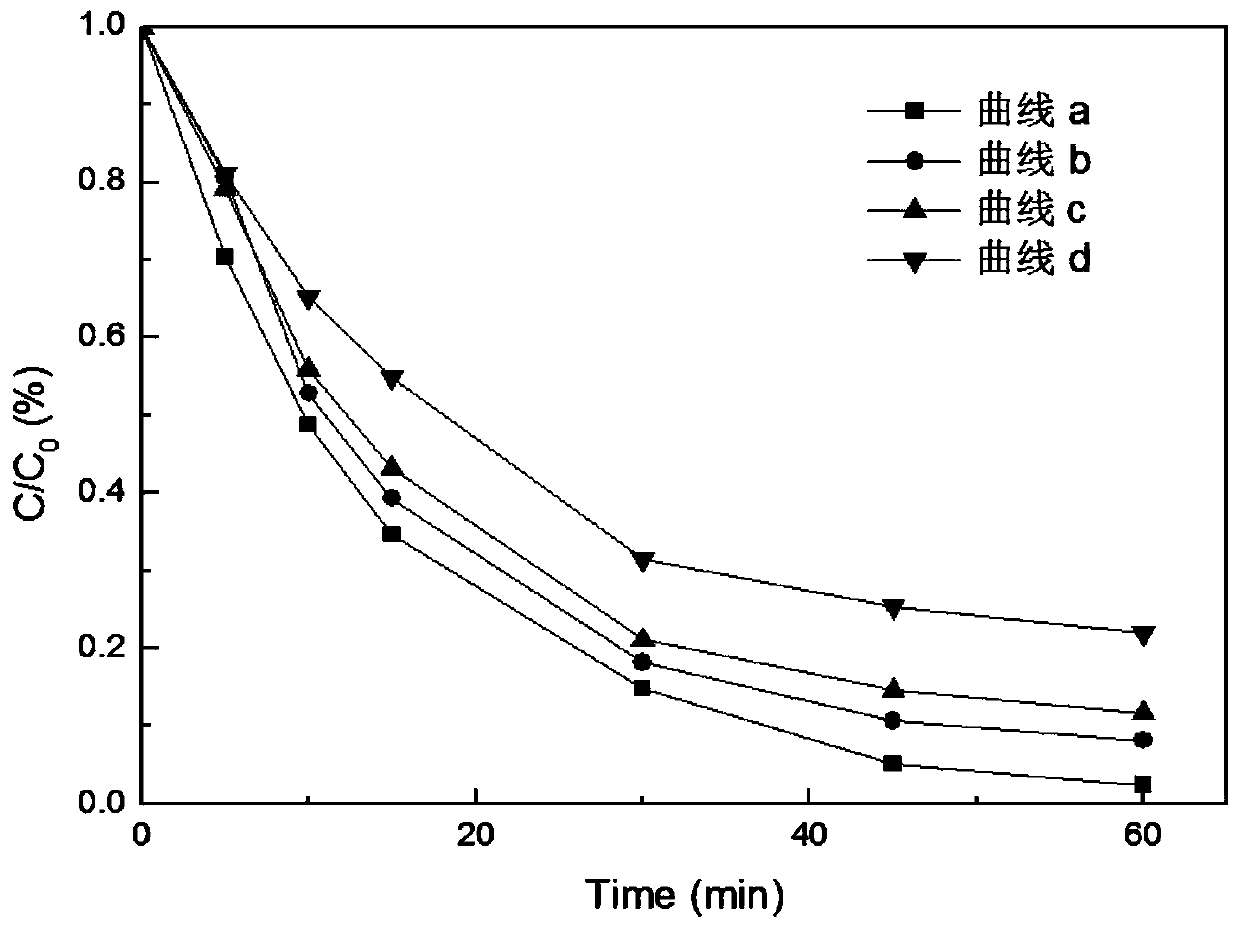

[0031] The specific preparation process is the same as that in Example 1, except that step (2) is omitted, no PTFE emulsion is added, and the purpose is that no binder is added, the electrode prepared above is used as the cathode, the platinum sheet is used as the anode, and 0.05M sodium sulfate is used as the Electrolyte, pH=6.7, I=90mA, persulfate 1mM, degrade 300ml of atrazine wastewater with a concentration of 20mg / L, at 60min, the degradation rate of atrazine reaches about 91%, such as image 3 As shown in the middle curve (b), the utilization of persulfate is 51.4%, as Figure 4 It is shown in the histogram (b).

Embodiment 3

[0033] The specific preparation process is the same as that in Example 1, the difference is that the CuFe in step (4) is added 2 O 4The amount becomes 0.05g, resulting in 0.25wt% uniform CuFe 2 O 4 dispersion so that the CuFe in the final composite catalyst 2 O 4 The loading amount of 25%, the electrode prepared above was used as the cathode, the platinum sheet was used as the anode, 0.05M sodium sulfate was used as the electrolyte, pH=6.7, I=90mA, persulfate 1mM, degraded 300ml concentration of 20mg / L Aluminium Atrazine wastewater, the degradation rate of atrazine reached about 88% in 60min, such as image 3 As shown in the middle curve (c), the utilization rate of the shown persulfate is 52.5%, as shown in Figure 4 Histogram (c) is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com