Economic synthesis method of ultrathin SSZ-13 molecular sieve membrane

A synthesis method and molecular sieve technology, which is applied in the field of economical synthesis of ultra-thin SSZ-13 molecular sieve membranes, can solve problems such as the difficulty in preparing ultra-thin molecular sieve membranes, and achieve the effects of reducing synthesis costs, avoiding large-scale use, and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] An economical synthesis method of ultra-thin SSZ-13 molecular sieve membrane, the seed crystal is loaded on the porous carrier, after template agent solution or molecular sieve membrane synthesis mother liquor is impregnated, only a small amount of liquid (template agent solution or molecular sieve membrane synthesis mother liquor, and There is no direct contact with the membrane tube), and the amorphous particles in the seed layer are converted into molecular sieve crystals at fixed points, and finally a continuous molecular sieve membrane is formed. The prepared SSZ-13 molecular sieve membrane thickness can be between 100 and 2000 nanometers, with extremely high CO 2 -CH 4 Separation performance, specifically comprising the following steps:

[0032] (1) Perform ball milling on the all-silicon CHA molecular sieve seed crystals. After ball milling, the molecular sieve crystals obtained from the CHA nanocrystal seeds are deeply fragmented and amorphous, and what are obt...

Embodiment 1

[0039] In this example, SSZ-13 molecular sieve membranes were synthesized by heating in a traditional oven. The specific steps are as follows:

[0040] Step 1: Synthetic formula of all-silicon CHA molecular sieve: 1.0SiO 2 :0.5HF:0.5TMAdaOH:3H 2 O (TMAdaOH: trimethylammonium adamantyl hydroxide). Ethyl orthosilicate and ammonium trimethylammonium hydroxide were mixed, stirred for 4 hours, then removed excess water and ethanol in an oven at 80 degrees Celsius, then added hydrofluoric acid, and stirred to obtain a synthetic mother liquor. Then crystallize at 453K for 24 hours to obtain an all-silicon CHA molecular sieve. The molecular sieve crystals are relatively large, about 8 microns. After being ball-milled by a ball mill, the crystals are pulverized to below 500 nanometers. Disperse the milled seed crystals in water to form a 0.1-0.4 wt% seed crystal dipping solution.

[0041] Step 2, select a porous ceramic tube with a pore size of 100nm as the carrier, seal the two e...

Embodiment 2

[0051] The difference from Example 1 is: in step 4, the porous carrier tube is immersed in 1.2 mol / liter ammonium trimethylammonium hydroxide solution (25wt%) for 1 minute, and in step 5, the crystallization kettle is put into 0.76g 25% TMAdaOH solution, all the other steps are the same as in Example 1.

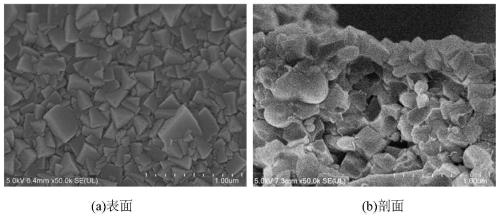

[0052] The surface and profile of gained SSZ-13 molecular sieve membrane are as follows figure 2 shown, from figure 2 It can be seen that the surface of the carrier is completely covered by cubic crystals, and the cross-linking between the crystals is perfect (see figure a); the thickness of the film is relatively uniform, about 1.1 micron nm (see figure b).

[0053] The CO of the SSZ-13 molecular sieve membrane tube 2 / CH 4 The gas separation test results are shown in Table 1. Under 0.2MPa, the CO 2 The average value of the permeability is 21×10 -7 mol / (m 2 s Pa), CO 2 / CH 4 The average value of separation selectivity is 121.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com