A siderite fluidized oxidation-reduction magnetization roasting system and method

A magnetization roasting and oxidative roasting technology, which is applied in the fields of mineral processing and metallurgy, can solve the problems of increasing the thermal load of the system, affecting the overall energy consumption, affecting the continuous production, etc., and achieving the effect of energy balance optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

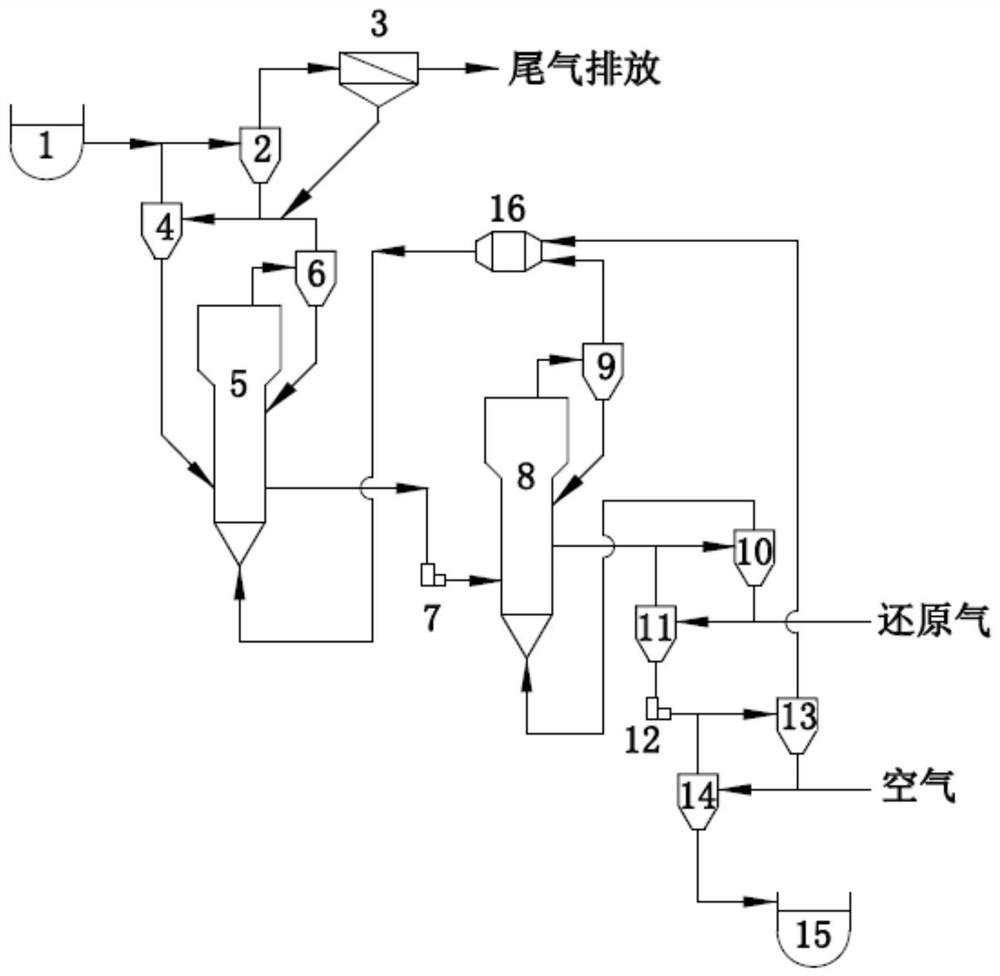

[0038] Such as figure 1 As shown, a siderite fluidized redox magnetized roasting system, the fluidized redox magnetized roasting system includes a feed bin, a preheater, a fluidized oxidation roaster, a burner, a fluidized magnetized Roasting furnace, reducing gas cooler, air cooler and discharge silo,

[0039] The preheater includes a two-stage preheating cyclone and a bag filter 3, and the fluidized oxidation roaster includes an oxidation roaster body 5, an oxidation cyclone separator 6, and an oxidation discharge valve 7. The magnetized roaster includes a magnetized roaster body 8 and a magnetized cyclone separator 9, the reducing gas cooler includes a two-stage reducing gas cooling cyclone and a cooling discharge valve 12, and the air cooler includes a two-stage air cooling cyclone, wherein, The outlet of the feed bin 1 is connected to the air inlet of the first-stage preheating cyclone 2, the top air outlet of the first-stage preheating cyclone 2 is connected to the air ...

Embodiment 2

[0053] Adopt above-mentioned siderite fluidized redox magnetization roasting system to carry out siderite fluidized roasting method as follows:

[0054] The siderite ore is stored in the feed bin and enters the preheater. In the multi-stage preheating cyclone, the ore powder and the hot flue gas tail gas of the fluidized oxidation roaster perform gas-solid countercurrent heat exchange to raise the temperature. The heated hot ore powder enters the oxidation process. The body of the roaster reacts with the hot flue gas for oxidative decomposition and modification. The oxidized ore powder entrained by the air flow is separated from the gas and solid by the oxidation cyclone separator and then returns to the body of the oxidized roaster. The oxidized ore powder is discharged from the outlet of the oxidized roaster body. Then enter the body of the magnetization roasting furnace through the oxidation discharge valve and carry out the magnetization roasting of the iron-containing phas...

Embodiment 3

[0057] The iron grade TFe treated by the invention is 25.3%, the iron element distribution in the siderite-containing phase accounts for 56.9% of the total iron, and the particle size is 0.037-2mm, of which -0.074mm accounts for 50%. Other iron oxides in ore powder are red limonite phase Fe 2 o 3 exist.

[0058] First, the fine ore enters the two-stage cyclone preheater from the silo to exchange heat with the exhaust gas of the oxidation furnace to raise the temperature, and then enters the fluidized bed oxidation roaster for calcination for 10 minutes at a temperature of 650°C and the hot flue gas atmosphere produced by the burner. The siderite is fully decomposed and oxidized in the fluidized bed oxidation roaster. Then it enters the fluidized bed magnetization roasting furnace through the discharge valve of the oxide ore, and performs magnetization reduction roasting with preheated producer gas at 475°C for 20 minutes. Producer gas composition is 20%CO+11%CO 2 +17%H 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com