A kind of graphene oxide, sepiolite, polyamide 6 composite material and preparation method thereof

A composite material and sepiolite technology, applied in the direction of single-component polyamide rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as poor modification effect, poor dispersion, and flammability of polyamide 6 , to achieve the effect of low modification cost, uniform dispersion and full dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

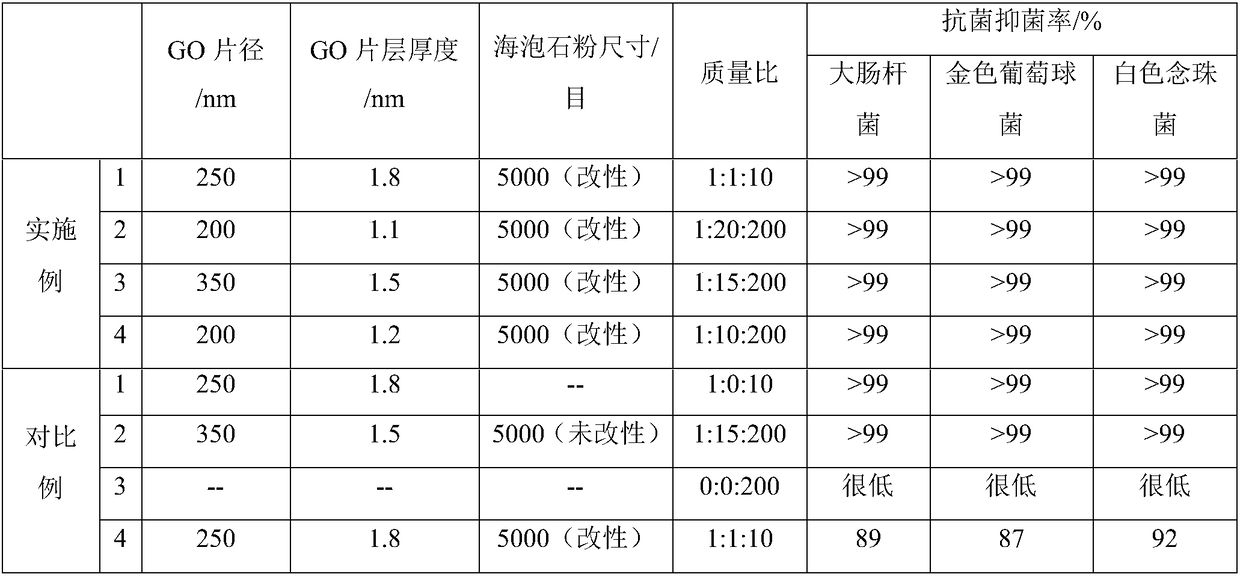

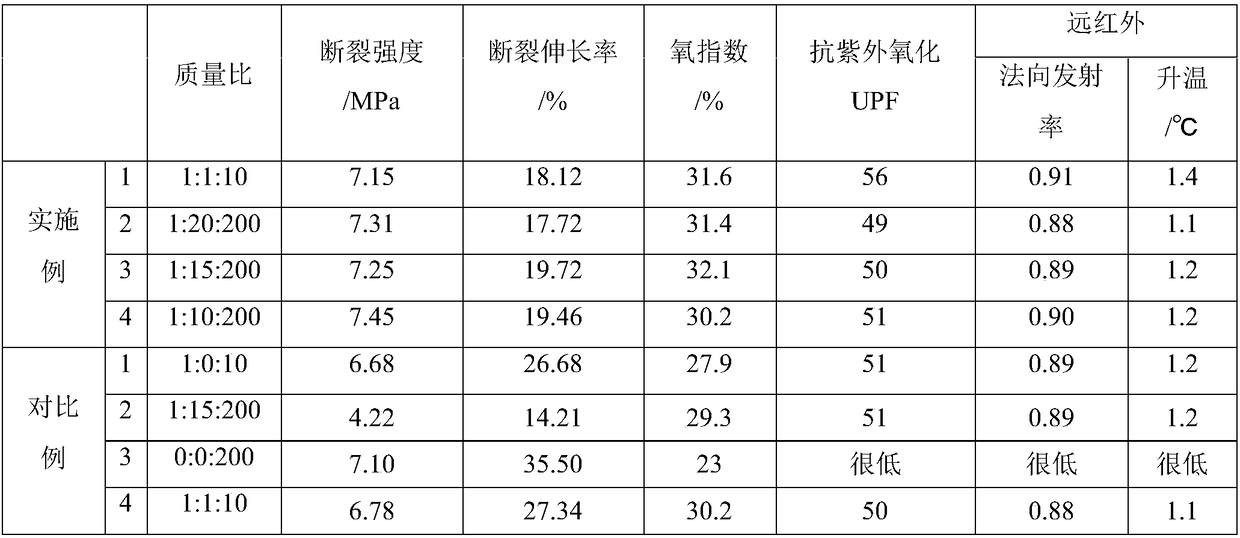

Embodiment 1

[0031] Step 1, spray-dry 100kg graphene oxide slurry to obtain graphene oxide powder, the solid content of the graphene oxide slurry is 3%, purchased from Changzhou Sixth Element Materials Technology Co., Ltd.; then deionized The graphene oxide powder is washed and suction-filtered multiple times with water to obtain a graphene oxide filter cake, and the graphene oxide filter cake is microwave-dried to obtain pure graphene oxide powder. The purpose of washing and suction filtration is to remove Ka, Na, Mn, Ca, Mg, Al and other metal ions remaining in the graphene oxide preparation process.

[0032] Step 2, disperse the graphene oxide powder obtained in step 1 in 100kg of DMF solution, and obtain the graphene oxide DMF dispersion liquid through the composite mixing and dispersion mode of ultrasonic, shearing and emulsification simultaneously, and spray the dispersion liquid Dry to obtain nanoscale graphene oxide powder with a high monolayer rate, the obtained graphene oxide pow...

Embodiment 2

[0040] Step 1, 100kg of graphene oxide slurry is spray-dried to obtain graphene oxide powder, then the graphene oxide powder is washed and suction-filtered several times with deionized water to obtain a graphene oxide filter cake, and the graphene oxide powder is The filter cake was dried by microwave to obtain pure graphene oxide powder.

[0041] In step 2, ultrasonically disperse the graphene oxide powder obtained in step 1 in 100kg of N-methylpyrrolidone, and process it through high-frequency ultrasonic, high-speed shearing, and emulsification composite technology for 2 hours to obtain an N-methylpyrrolidone dispersion of graphene oxide, The dispersion liquid is spray-dried to obtain nanoscale graphene oxide powder with a high single-layer ratio. The obtained graphene oxide powder has a sheet diameter of 500 nm and a sheet thickness of 1.0 nm.

[0042] In step 3, the graphene oxide powder obtained in step 2 is dispersed in the aminocaproic acid aqueous solution at a ratio o...

Embodiment 3

[0049] Step 1, 100kg of graphene oxide slurry is spray-dried to obtain graphene oxide powder, then the graphene oxide powder is washed and suction-filtered several times with deionized water to obtain a graphene oxide filter cake, and the graphene oxide powder is The filter cake was dried by microwave to obtain pure graphene oxide powder.

[0050] Step 2, ultrasonically disperse the graphene oxide powder obtained in step 1 in 100kg of tetrahydrofuran, and process it for 3 hours through high-frequency ultrasonic, high-speed shearing, and emulsification composite technology to obtain a tetrahydrofuran dispersion of graphene oxide, and spray-dry the dispersion Nanoscale graphene oxide powder with a high monolayer ratio is obtained. The sheet diameter of the obtained graphene oxide powder is about 350 nm, and the sheet thickness is about 1.5 nm.

[0051] Step 3, the graphene oxide powder obtained in step 2 is dispersed in the aminocaproic acid aqueous solution according to the rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com