A kind of heat-conducting nylon composite material and preparation method thereof

A technology for nylon composite materials and raw materials, which is applied in the field of thermally conductive nylon composite materials and their preparation, can solve problems such as limited improvement of composite materials, and achieve the effects of improving mechanical properties and wear resistance, improving shrinkage rate and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

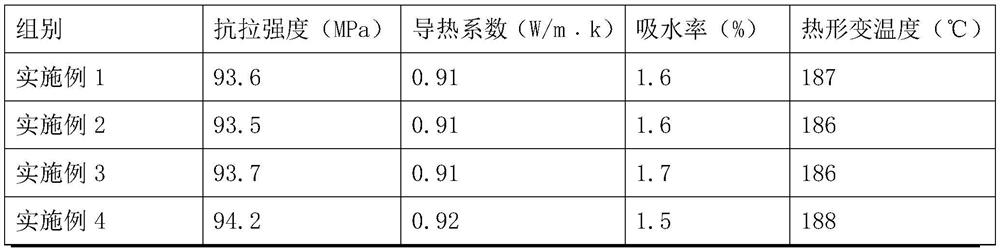

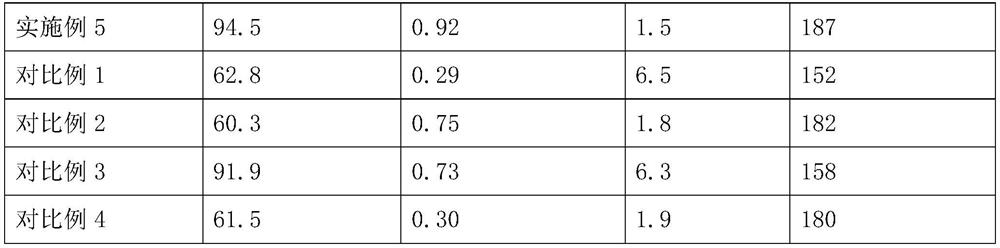

Examples

Embodiment 1

[0025] Composition of raw materials (parts by weight): 1000 parts of caprolactam, 12 parts of light-burned magnesia, 10 parts of superfine talc powder, 30 parts of nano-alumina, 20 parts of attapulgite powder, 2 parts of sodium hydroxide, 12 parts of graphene, silica gel 5 parts of powder, 10 parts of boron nitride, 1 part of TDI activator, 3 parts of reinforcing agent, 1 part of lubricant and 2 parts of coupling agent.

[0026] The coupling agent is silane coupling agent KH-550.

[0027] The lubricant is a mixture of molybdenum disulfide, liquid paraffin and tetrafluoroethylene micropowder, and the mass ratio is 1:2:2.

[0028] The reinforcing agent is a mixture of carbon fiber, glass fiber and wollastonite, with a mass ratio of 1:1:2.

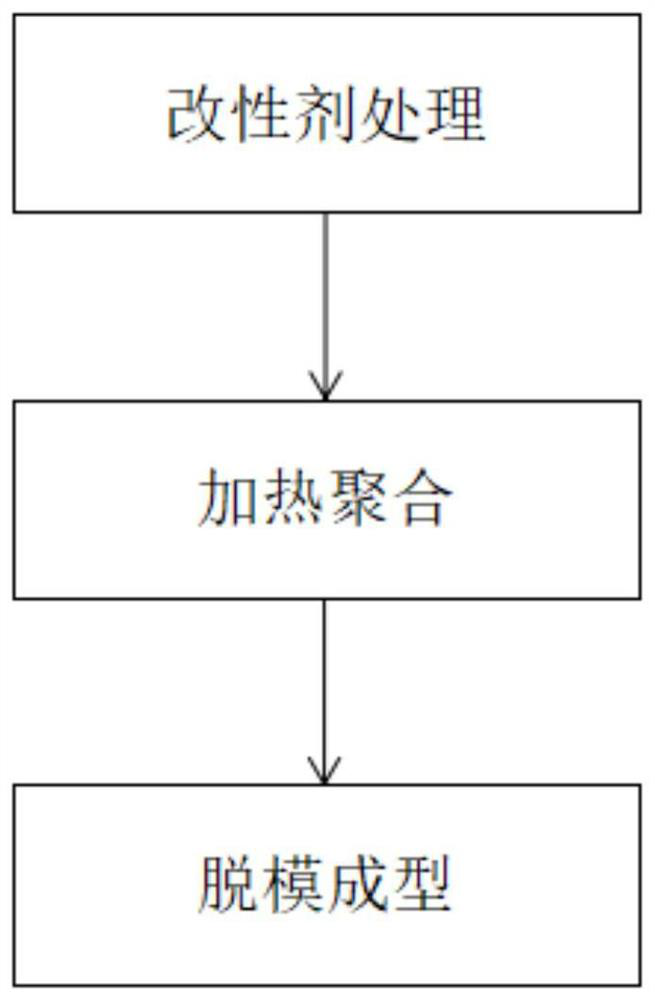

[0029] A method for preparing a thermally conductive nylon composite material is prepared according to the following method:

[0030] S1. Mix light-burned magnesia, superfine talc powder, nano-alumina, attapulgite powder, graphene, silica g...

Embodiment 2

[0033] Composition of raw materials (parts by weight): 2000 parts of caprolactam, 18 parts of light-burned magnesia, 15 parts of superfine talc powder, 40 parts of nano-alumina, 30 parts of attapulgite powder, 5 parts of sodium hydroxide, 17 parts of graphene, silica gel 12 parts of powder, 20 parts of boron nitride, 3 parts of TDI activator, 9 parts of reinforcing agent, 4 parts of lubricant and 5 parts of coupling agent.

[0034] The coupling agent is a mixture of silane coupling agents KH-560 and KH-570 with a mass ratio of 1:2.

[0035] The lubricant is a mixture of molybdenum disulfide, liquid paraffin and tetrafluoroethylene micropowder, and the mass ratio is 1:2:2.

[0036] The reinforcing agent is a mixture of carbon fiber, glass fiber and wollastonite, with a mass ratio of 1:1:2.

[0037] A method for preparing a thermally conductive nylon composite material is prepared according to the following method:

[0038] S1. Mix lightly burned magnesia, superfine talc powde...

Embodiment 3

[0041] Composition of raw materials (parts by weight): 1300 parts of caprolactam, 14 parts of light-burned magnesia, 12 parts of superfine talc powder, 32 parts of nano-alumina, 22 parts of attapulgite powder, 3 parts of sodium hydroxide, 14 parts of graphene, silica gel 7 parts of powder, 12 parts of boron nitride, 1 part of TDI activator, 4 parts of reinforcing agent, 2 parts of lubricant and 3 parts of coupling agent.

[0042] The coupling agent is a silane coupling agent Sj-42.

[0043] The lubricant is a mixture of molybdenum disulfide, liquid paraffin and tetrafluoroethylene micropowder, and the mass ratio is 1:2:2.

[0044] The reinforcing agent is a mixture of carbon fiber, glass fiber and wollastonite, with a mass ratio of 1:1:2.

[0045] A method for preparing a thermally conductive nylon composite material, which is prepared according to the following method:

[0046] S1. Mix lightly burned magnesia, superfine talc powder, nano-alumina, attapulgite powder, graphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com