Preparation method of polyamide composite nanofiltration membrane for removing heavy metal pollutants

A composite nanofiltration membrane and pollutant technology, which is applied in the direction of water pollutants, chemical instruments and methods, membrane technology, etc., can solve problems such as obvious agglomeration, and achieve the effect of improving dispersion and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Ⅰ The preparation process of modified silica nanoparticles containing halogen groups on the surface is as follows:

[0053] 10g SiO 2 (with a particle size of 7-40nm) was added to 250ml of N,N-dimethylformamide, and stirred to obtain a nanoparticle dispersion; while stirring, 6ml of 3-chloropropyltriethoxysilane was added, and kept stirring, at 80°C After reacting for 12 hours under the same conditions, take the reaction product and centrifuge it, wash it with absolute ethanol and centrifuge again, repeat the operation three times, dry it in vacuum for 48 hours, and grind the obtained solid substance with a mortar for 5 minutes to obtain SiO 2 -Cl;

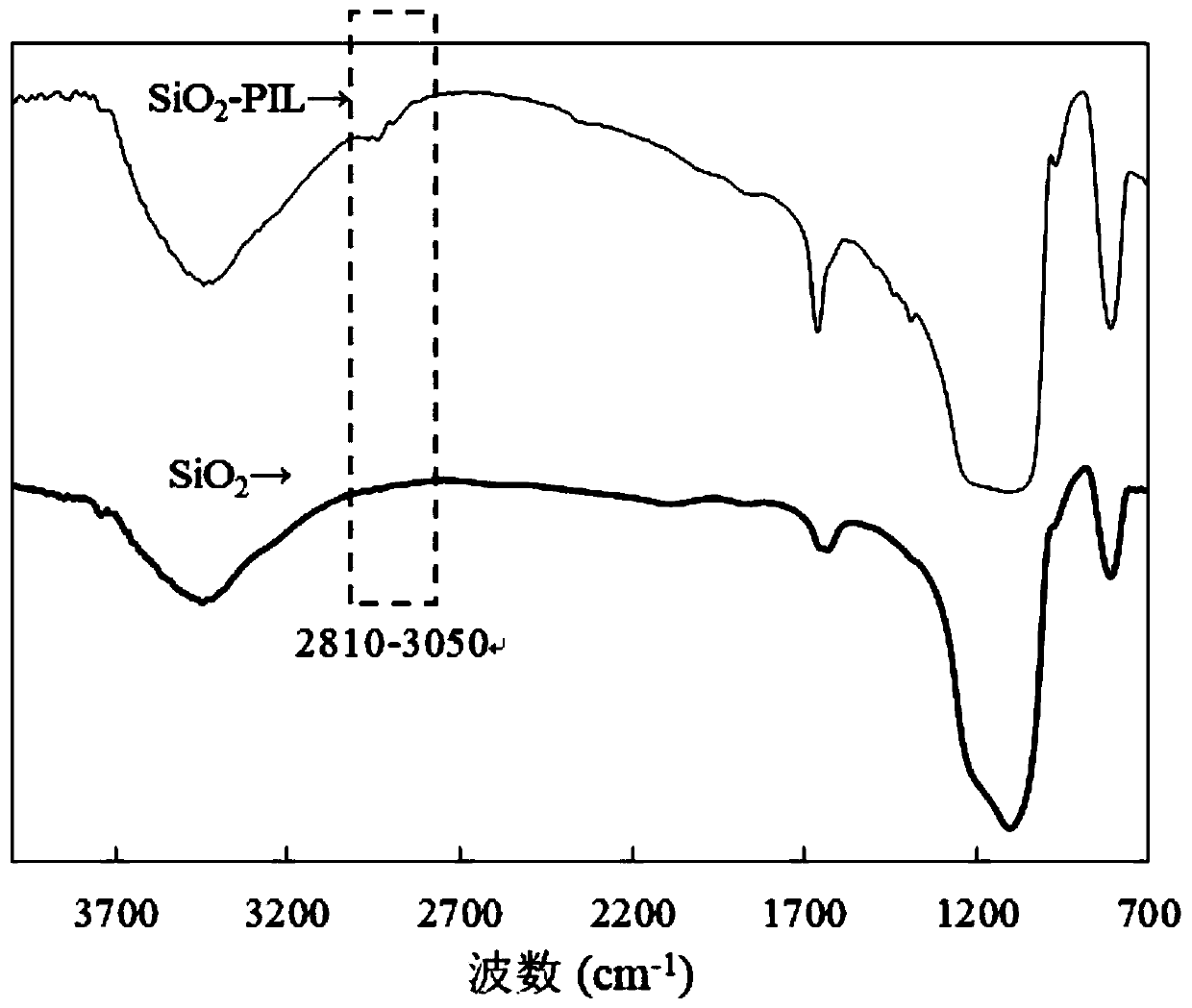

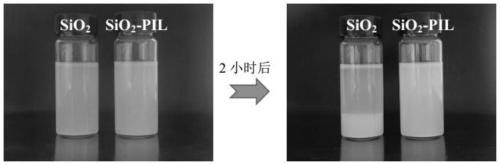

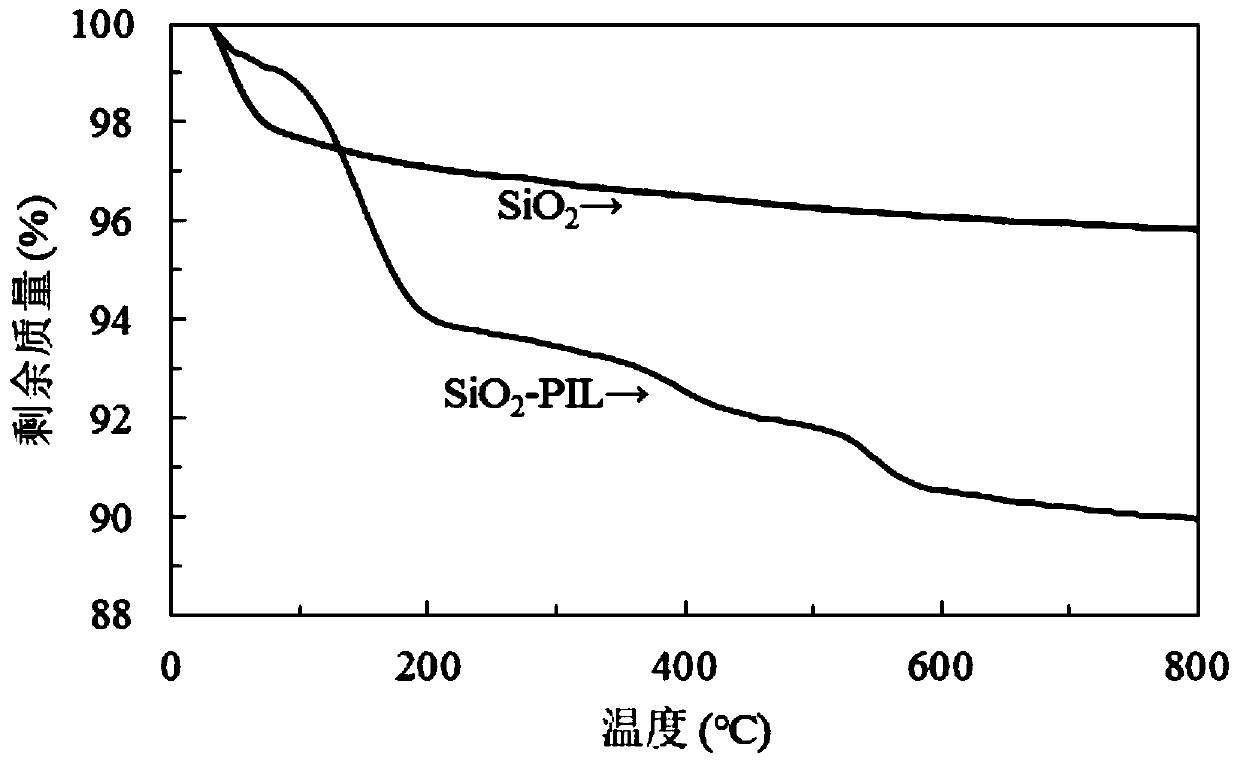

[0054] II The preparation process of the modified silica nanoparticles (silica-polyionic liquid particles) containing polyionic liquid on the surface is as follows:

[0055] Take 0.10 g of copper bromide, 0.10 g of 2,2'-bipyridine, 20 g of 1-allyl-3-methylimidazolium hexafluorophosphate and 5.0 g of SiO 2 -Cl was dispers...

Embodiment 2

[0060] Ⅰ The preparation process of modified silica nanoparticles containing halogen groups on the surface is as follows:

[0061] 10g SiO 2 (with a particle size of 7-40nm) was added to 250ml of N,N-dimethylformamide, and stirred to obtain a nanoparticle dispersion; while stirring, 6ml of 3-chloropropyltriethoxysilane was added, and kept stirring, at 80°C After reacting for 12 hours under the same conditions, take the reaction product and centrifuge it, wash it with absolute ethanol and centrifuge again, repeat the operation three times, dry it in vacuum for 48 hours, and grind the obtained solid substance with a mortar for 5 minutes to obtain SiO 2 -Cl;

[0062] II The preparation process of the modified silica nanoparticles (silica-polyionic liquid particles) containing polyionic liquid on the surface is as follows:

[0063] Take 0.10g of copper bromide, 0.10g of 2,2'-bipyridine, 20g of 1-allyl-3-methylimidazolium bromide and 5.0g of SiO 2 -Cl was dispersed in 200ml of N...

Embodiment 3

[0068] Ⅰ The preparation process of modified silica nanoparticles containing halogen groups on the surface is as follows:

[0069] 10g SiO 2 (with a particle size of 7-40nm) was added to 250ml of N,N-dimethylformamide, and stirred to obtain a nanoparticle dispersion; while stirring, 6ml of 3-chloropropyltriethoxysilane was added, and kept stirring, at 80°C After reacting for 12 hours under the same conditions, take the reaction product and centrifuge it, wash it with absolute ethanol and centrifuge again, repeat the operation three times, dry it in vacuum for 48 hours, and grind the obtained solid substance with a mortar for 5 minutes to obtain SiO 2 -Cl;

[0070] II The preparation process of the modified silica nanoparticles (silica-polyionic liquid particles) containing polyionic liquid on the surface is as follows:

[0071] Take 0.10 g of copper bromide, 0.10 g of 2,2'-bipyridine, 10 g of 1-allyl-3-methylimidazolium tetrafluoroborate and 5.0 g of SiO 2 -Cl was dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com